Method for reducing decomposition of cephalosporin C

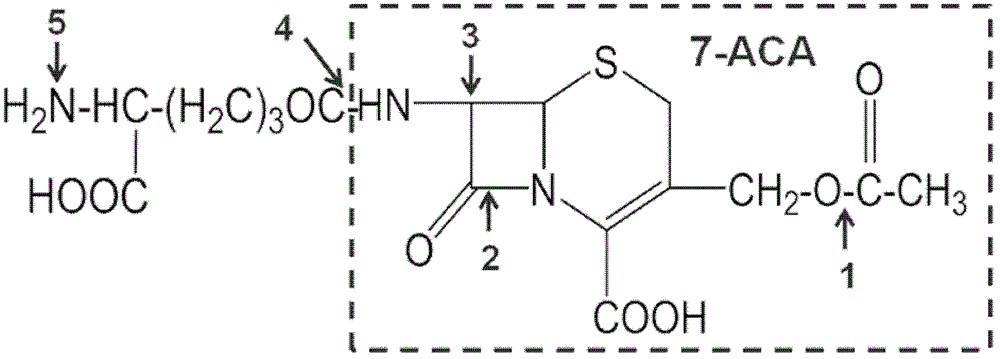

A technology of cephalosporin and aminocephalosporanic acid, which is applied in the field of bioengineering, can solve the problems of low utilization rate of CPC and reduce the decomposition of cephalosporin C, etc., achieve the improvement of substrate utilization rate, reduce the cost of raw materials, and the operation method is fast and efficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Decomposition of CPC by E.coli JM105 (Saibaisheng Company), JM109 (DE3) (Dingguo Company) and BL21 (DE3) (Promega Company) cell lysate

[0032] (1) Preparation of cell lysate and crude enzyme solution:

[0033] In the 10ml LB medium containing 50mg / L kanamycin (the medium consists of: peptone 10g.L -1 , yeast powder 5g.L -1 , sodium chloride 10g.L -1 , pH 7.0) were inoculated with single colonies of Escherichia coli JM105, JM109(DE3) and BL21(DE3), cultured at 37°C and 200rpm for 12h, and made seed bottles. Take 1mL of bacterial solution and transfer to a solution containing 50mg.L -1 Kanamycin 50ml (300ml shake flask) fermentation medium. Among them, the inducible medium of Escherichia coli JM109 (DE3) and BL21 (DE3) is: corn steep liquor 50g.L -1 , yeast extract 10g.L -1 , NH 4 Cl 2.5g.L -1 , glycerin 5g.L -1 , KH 2 PO 4 2.3g.L -1 , K 2 HPO 4 .3H 2 O 20.4g.L -1 , Lactose 3g.L -1 , pH 7.5. The constitutive medium of Escherichia coli JM105 is: corn st...

Embodiment 2

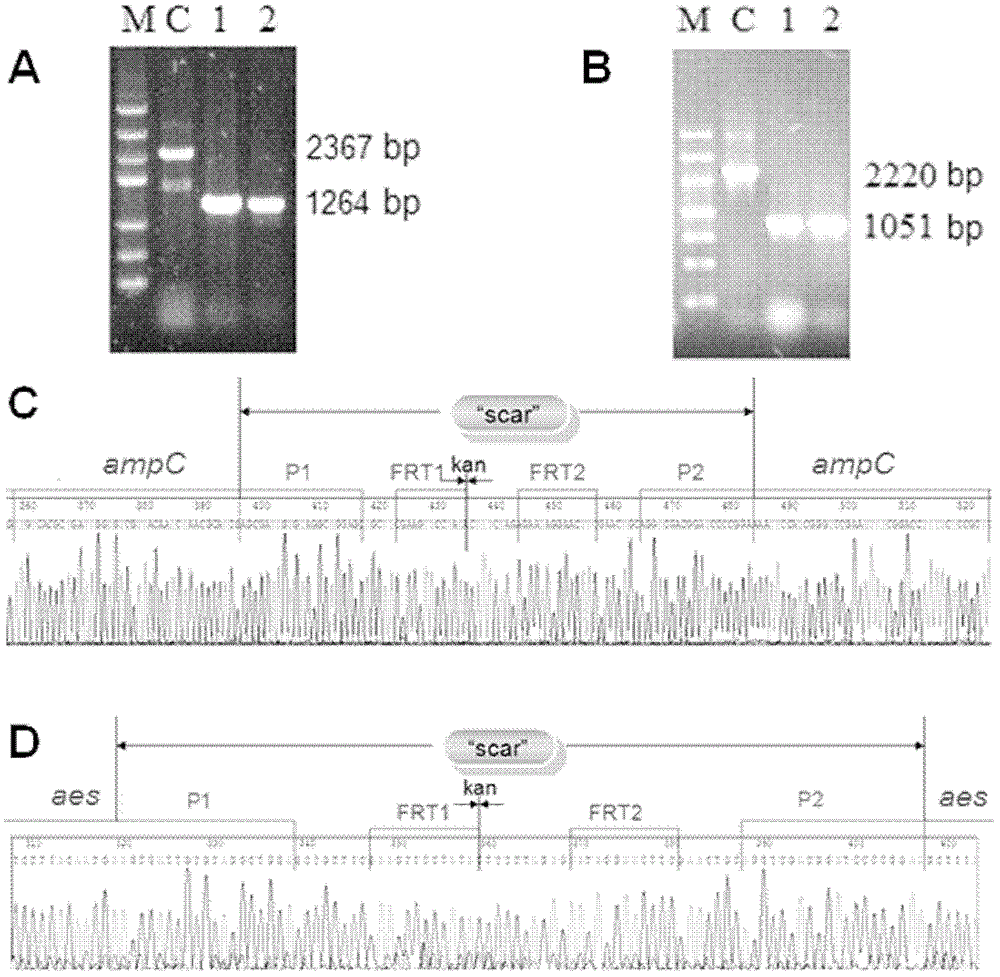

[0039] Knockout of β-lactamase and acetylesterase in E.coli JM105 and JM109(DE3)

[0040] (1) Knockout of β-lactamase gene ampC:

[0041] The genome sequence analysis of Escherichia coli E.coli K12 showed that the β-lactamase gene ampC (E.coli K12 gene ID948669) and the acetyl esterase gene aes existed in the genomes of E.coli JM105 and JM109(DE3) (E. coli K12 gene ID 947514). Homologous arm primer pair ampCP1 / ampCP2 were designed, respectively containing 40bp upstream and downstream fragments of ampC gene and 19bp kanamycin resistance gene fragment, which were synthesized by Yingwei Jieji Bioengineering Technology Co., Ltd. (Beijing). The helper plasmid pKD13 was used as a template to amplify the DNA fragment of the kanamycin resistance gene inside and the ampC homology arm outside. A 50 μL system was used for PCR amplification, and the composition was as follows:

[0042]

[0043]

[0044] Among them, rTaq DNA polymerase and dNTPs were purchased from Takara Company ...

Embodiment 3

[0056] Decomposition of CPC by Cell Lysate of β-lactamase and Acetylesterase Knockout Engineering Bacteria

[0057] According to the method described in Example 1, cultivate the following three kinds of β-lactamase and acetyl esterase knockout type engineering bacteria E.coli JM105 (ΔampC), E.coli JM105 (Δaes), E.coli JM105 ( ΔampC, Δaes), and E.coli JM105 was used as the control. Determination of cell growth curves, such as Figure 4 As shown in A. The results showed that knockout of β-lactamase and acetylesterase had no significant effect on the growth of recombinant bacterial cells. According to the method as described in Example 1, the cell lysate of each bacterial strain was prepared, and the cell lysate of the bacterial strain before natural degradation and double enzyme knockout was used as a control to investigate the effect of each cell lysate CPC decomposition, the results are as follows Figure 4 Shown in B. The E.coli JM105 cell lysate without gene knockout deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com