Special oil for oil-bath type air cleaner

An air filter and special oil technology, which is applied in the chemical industry, can solve the problems of high cost, poor filtering effect, and failure to meet the use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

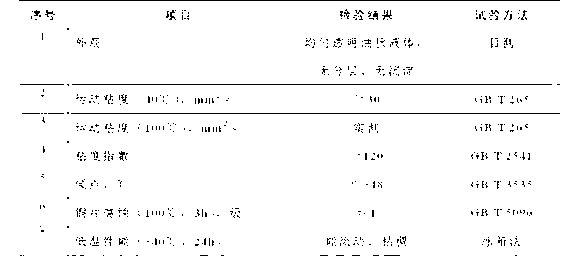

Image

Examples

Embodiment 1

[0030] The present invention makes the material parts by weight of oil composition and consists of:

[0031] L-AN32 total loss system oil base oil 87.0

[0032] Alkylated naphthalene pour point depressant (T801) 0.5

[0033] Ethylene Propylene Copolymer Viscosity Index Improver (T612) 2.0

[0034] Sodium petroleum sulfonate rust inhibitor (T702) 2.0

[0035] Benzotriazole copper corrosion inhibitor (T706) 0.1

[0036] Methyl silicone oil antifoam agent (T901) 0.0005.

[0037] Production Process:

[0038] 1. Add the specified amount of base oil into the container and heat it to 65℃±5℃ under stirring.

[0039] 2. Slowly add the pour point depressant to the base oil under the above temperature and stirring, and then continue stirring for about 30 minutes.

[0040] 3. Slowly add the viscosity index improver to the above oil under the above temperature and stirring, and then continue to stir for about 30 minutes.

[0041] 4. Slowly add the anti-rust agent into the above oil ...

Embodiment 2

[0046] The present invention makes the material parts by weight of oil composition and consists of:

[0047] L-AN32 total loss system oil base oil 91

[0048] Alkylated naphthalene pour point depressant (T801) 1.25

[0049] Ethylene-propylene copolymer viscosity index improver (T612) 3.5

[0050] Sodium petroleum sulfonate rust inhibitor (T702) 4

[0051] Benzotriazole copper corrosion inhibitor (T706) 0.2

[0052] Methyl silicone antifoam agent (T901) 0.00275.

[0053] Production technology is identical with embodiment 1.

Embodiment 3

[0055] The present invention makes the material parts by weight of oil composition and consists of:

[0056] L-AN32 total loss system oil base oil 95.0

[0057] Alkylated naphthalene pour point depressant (T801) 2.0

[0058] Ethylene Propylene Copolymer Viscosity Index Improver (T612) 5.0

[0059] Sodium petroleum sulfonate rust inhibitor (T702) 6.0

[0060] Benzotriazole copper corrosion inhibitor (T706) 0.3

[0061] Methyl silicone oil antifoam agent (T901) 0.005.

[0062] Production technology is identical with embodiment 1.

[0063] Use of the present invention:

[0064]The oil-bath air filter has upper and lower shells (with air inlet and outlet ports on the shell), and an oil pool inside the lower shell, and a certain amount (about 4L) of special oil (that is, the patented product of the present invention) is added to the oil pool. (It is not suitable for too much oil or too little oil). The upper shell is composed of filter screens wound with metal wires and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com