Method for selective hydrocracking of light oil

A hydrocracking and selective technology, applied in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc., can solve the problem of high production cost, achieve high light oil selectivity, high chemical raw material selectivity, and diffusion-friendly technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

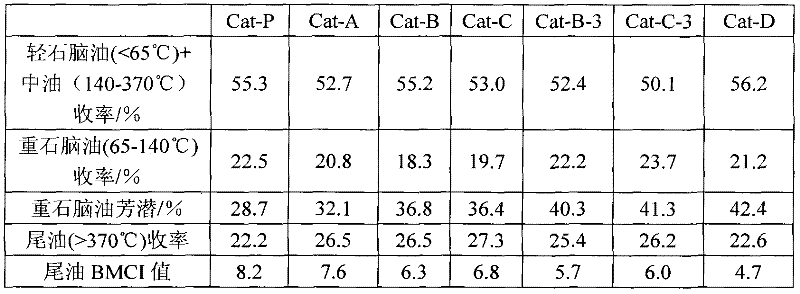

Examples

Embodiment 1

[0022] Prepare the directing agent and mother liquor according to Comparative Example 1. After the mother liquor is prepared, add 4.0 g of solid β molecular sieve with a silicon-aluminum ratio of 25 to the mother liquor of Y molecular sieve, and stir vigorously to obtain a suspension containing β molecular sieve, then add the guiding agent dropwise into the mother liquor, and stir vigorously 20min. The above materials were placed in a 300mL polytetrafluoroethylene-lined crystallization kettle, aged at room temperature for 24h, and then crystallized at 100°C for 22h. After the crystallization is completed, filter and wash until the pH of the filtrate is less than 9, and dry to obtain the Na-type β / Y composite molecular sieve. Add β / Y composite molecular sieve to 1.0mol L -1 NH 4 NO 3 In the aqueous solution, the solid-to-liquid ratio was 1:10, and stirred in a constant temperature reactor at 95°C for 3h. After the exchange, filter and wash until neutral, fully dry, and roa...

Embodiment 2

[0025] Prepare the directing agent and mother liquor according to Comparative Example 1. Then the directing agent was added dropwise to the mother liquor and stirred vigorously for 20 minutes. Then add 4.0g of solid β molecular sieve with a silicon-aluminum ratio of 25 into the synthesis system of Y molecular sieve, and after vigorous stirring to obtain a suspension containing Y molecular sieve, put the above material in a 300mL crystallizer with a polytetrafluoroethylene liner. In the kettle, it was aged at room temperature for 24h, and then crystallized at 100°C for 22h. After the crystallization is completed, filter and wash to pH-1 NH 4 NO 3 In the aqueous solution, the solid-to-liquid ratio was 1:10, and stirred in a constant temperature reactor at 95°C for 3h. After the exchange, filter and wash until neutral, fully dry, and roast in a muffle furnace at 500°C for 3 hours to obtain H-type β / Y composite molecular sieves.

[0026] The rest of the steps were prepared acc...

Embodiment 3

[0028] The addition of the β molecular sieve among the embodiment 1 is increased to 7g, and the content of the β molecular sieve in the composite molecular sieve becomes 30% this moment, all the other steps are unchanged, and the gained catalyst is recorded as Cat-B-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com