Coal direct hydrogenation liquefaction method rich in aromatics

A technology for hydroliquefaction and hydrocracking, which is applied in the preparation of liquid hydrocarbon mixture, hydrotreating process, and treatment of hydrocarbon oil, etc., can solve the problems of low energy utilization efficiency, underutilization, long process route, etc. Competitiveness, high aromatic potential, and the effect of increasing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

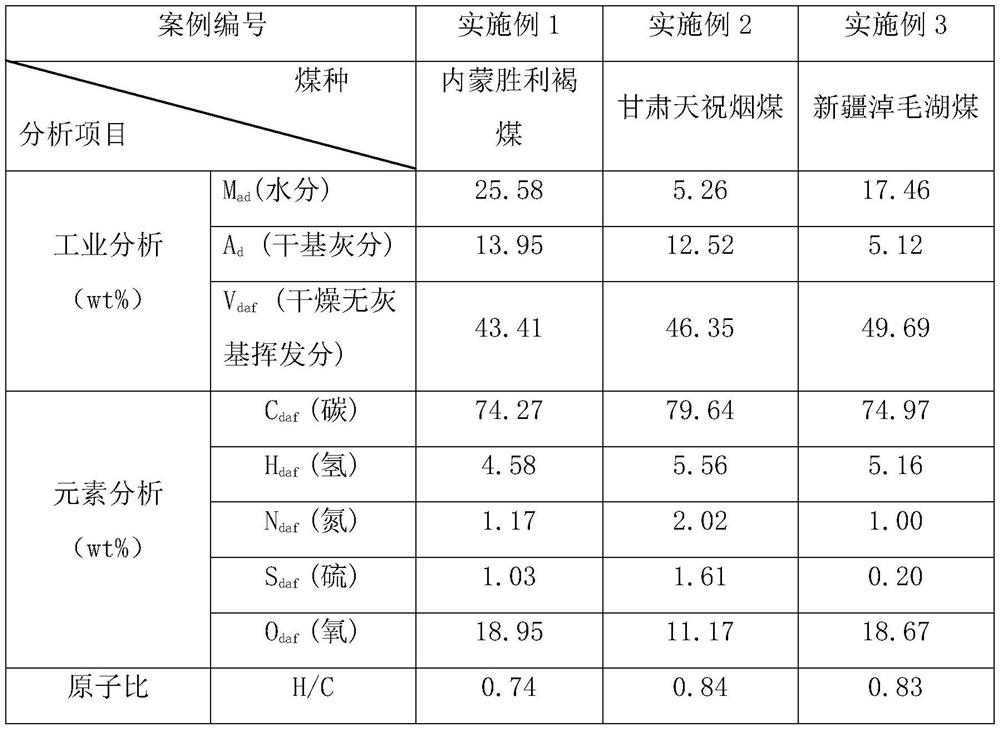

Embodiment 1

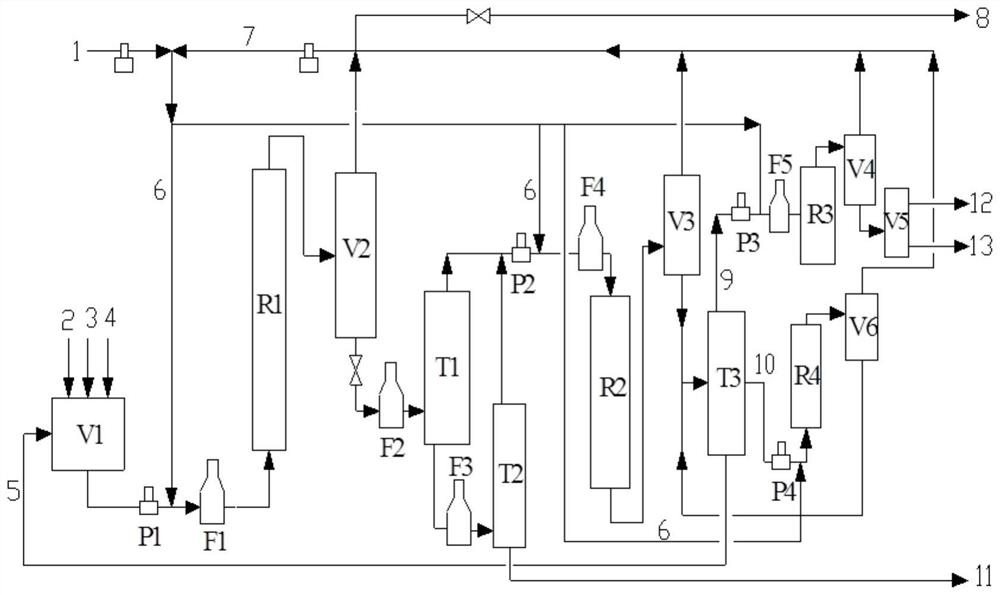

[0080] Such as figure 1 As shown, an embodiment of the present invention proposes a method for directly hydrogenating liquefaction of coal rich in aromatics, which includes:

[0081] The fresh hydrogen 1 is mixed with the circulating hydrogen 7 to obtain the mixed hydrogen 6; the raw coal 3 is pretreated, dried and broken into coal powder, and the external solvent 2, catalyst and co-catalyst 4, and circulating solvent 5 are added to the coal slurry preparation unit V1 in a certain proportion , stir and mix in V1 to form an oil-coal slurry with a viscosity lower than 500cp (60°C). The oil-coal slurry from V1 is pressurized by the high-pressure coal slurry pump P1 and mixed with the mixed hydrogen 6. After mixing, it is preheated by the preheater F1. The preheated oil-coal slurry enters the liquefaction reactor R1, and the The reaction product is sent to the gas-liquid separator V2 for gas-liquid separation. A part of the gas phase material in the separator V2 is mixed with fre...

Embodiment 2

[0087] An embodiment of the present invention proposes a method for directly hydrogenating liquefaction of coal rich in aromatics, which includes:

[0088] The fresh hydrogen 1 is mixed with the circulating hydrogen 7 to obtain the mixed hydrogen 6; the raw coal 3 is pretreated, dried and broken into coal powder, and the external solvent 2, catalyst and co-catalyst 4, and circulating solvent 5 are added to the coal slurry preparation unit V1 in a certain proportion , stir and mix in V1 to form an oil-coal slurry with a viscosity lower than 500cp (60°C). The oil-coal slurry from V1 is pressurized by the high-pressure coal slurry pump P1 and mixed with the mixed hydrogen 6. After mixing, it is preheated by the preheater F1. The preheated oil-coal slurry enters the liquefaction reactor R1, and the The reaction product is sent to the gas-liquid separator V2 for gas-liquid separation. A part of the gas phase material in the separator V2 is mixed with fresh hydrogen and recycled, an...

Embodiment 3

[0094] An embodiment of the present invention proposes a method for directly hydrogenating liquefaction of coal rich in aromatics, which includes:

[0095]The fresh hydrogen 1 is mixed with the circulating hydrogen 7 to obtain the mixed hydrogen 6; the raw coal 3 is pretreated, dried and broken into coal powder, and the external solvent 2, catalyst and co-catalyst 4, and circulating solvent 5 are added to the coal slurry preparation unit V1 in a certain proportion , stir and mix in V1 to form an oil-coal slurry with a viscosity lower than 500cp (60°C). The oil-coal slurry from V1 is pressurized by the high-pressure coal slurry pump P1 and mixed with the mixed hydrogen 6. After mixing, it is preheated by the preheater F1. The preheated oil-coal slurry enters the liquefaction reactor R1, and the The reaction product is sent to the gas-liquid separator V2 for gas-liquid separation. A part of the gas phase material in the separator V2 is mixed with fresh hydrogen and recycled, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com