A hydrocracking method for producing chemical raw materials

A technology of hydrocracking and chemical raw materials, which is applied in the fields of hydroprocessing process, petroleum industry, hydrocarbon oil treatment products, etc., and can solve the problem that the yield of heavy naphtha is not enough to meet the product demand, and the yield of light naphtha or light hydrocarbons High quality, increased complexity of the device, etc., to achieve the effect of excellent tail oil quality, small device investment, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

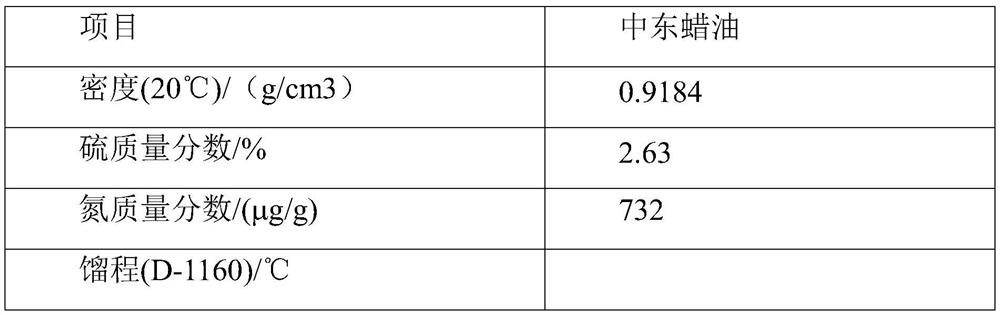

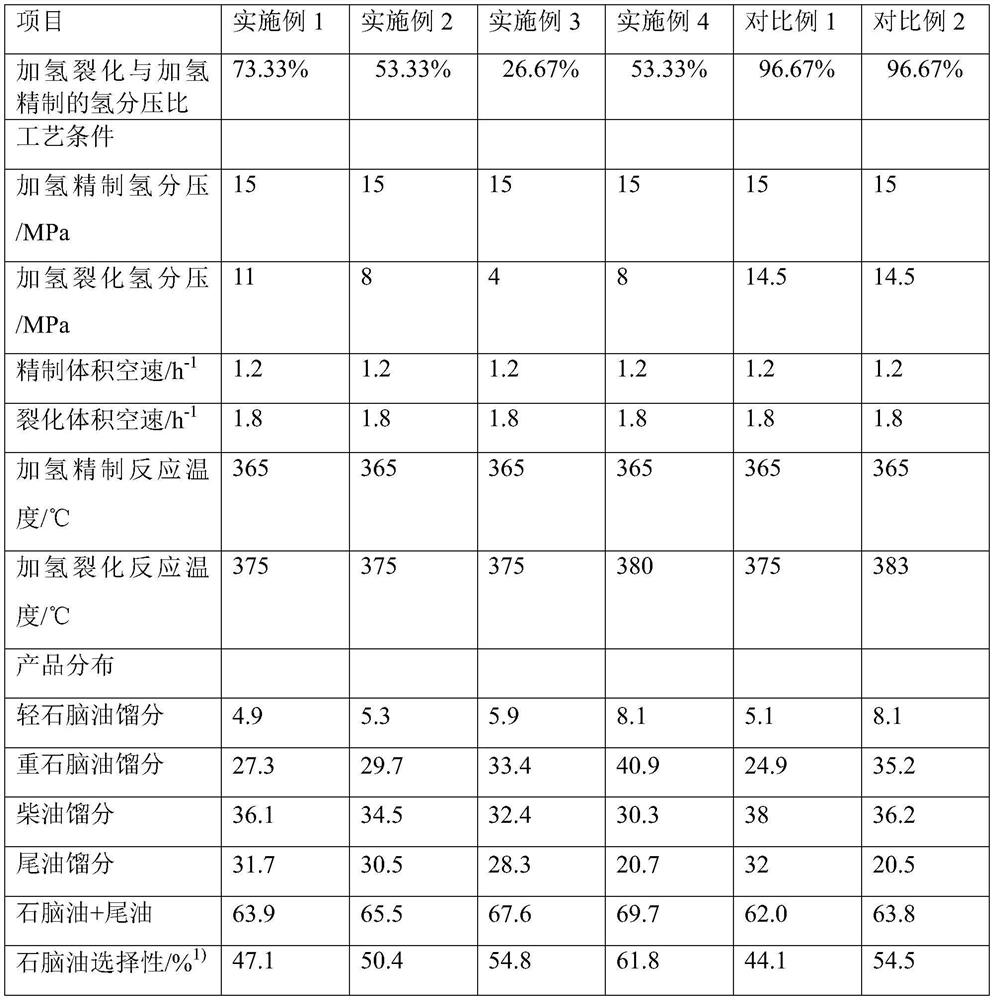

[0053] The raw materials in Table 1 are used as the feed, and the raw oil enters the hydrorefining reaction zone and the hydrocracking reaction zone successively for hydrogenation reaction in the presence of hydrogen, and the obtained reaction product is subjected to gas-liquid separation and fractionation to obtain pumice Naphtha fraction, heavy naphtha fraction, diesel oil fraction and tail oil fraction, the hydrofinishing reaction zone is filled with hydrofinishing catalyst RN-32V, and the hydrocracking reaction zone is filled with hydrocracking catalyst RHC-5. Process conditions, product distribution, and key product properties are listed in Tables 2 and 3.

[0054] As shown in Table 2 and Table 3, the hydrogen partial pressure in the hydrofinishing reaction zone is 15MPa, under the medium pressure of 11MPa hydrogen partial pressure in the hydrocracking reaction zone and the hydrocracking reaction temperature of 375°C, Middle East Wax After the oil is processed by the meth...

Embodiment 2

[0057] The raw materials in Table 1 are used as the feed, and the raw oil enters the hydrorefining reaction zone and the hydrocracking reaction zone successively for hydrogenation reaction in the presence of hydrogen, and the obtained reaction product is subjected to gas-liquid separation and fractionation to obtain pumice Naphtha fraction, heavy naphtha fraction, diesel oil fraction and tail oil fraction, the hydrofinishing reaction zone is filled with hydrofinishing catalyst RN-32V, and the hydrocracking reaction zone is filled with hydrocracking catalyst RHC-5. Process conditions, product distribution, and key product properties are listed in Tables 2 and 3.

[0058] As shown in Table 2 and Table 3, under the condition that the hydrogen partial pressure in the hydrocracking reaction zone is 8MPa and the hydrocracking reaction temperature is 375°C, after the Middle East wax oil is treated by the method in Example 2, the naphtha in the product+ The total yield of tail oil rea...

Embodiment 3

[0061] The raw materials in Table 1 are used as the feed, and the raw oil enters the hydrorefining reaction zone and the hydrocracking reaction zone successively for hydrogenation reaction in the presence of hydrogen, and the obtained reaction product is subjected to gas-liquid separation and fractionation to obtain pumice Naphtha fraction, heavy naphtha fraction, diesel oil fraction and tail oil fraction, the hydrofinishing reaction zone is filled with hydrofinishing catalyst RN-32V, and the hydrocracking reaction zone is filled with hydrocracking catalyst RHC-5. Process conditions, product distribution, and key product properties are listed in Tables 2 and 3.

[0062] As shown in Table 2 and Table 3, under the condition of low pressure of hydrogen partial pressure of 4MPa and cracking reaction temperature of 375°C in the hydrocracking reaction zone, after the Middle East wax oil is treated by the method in Example 3, naphtha+tail The total yield of oil reaches 67.6%, the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com