Rubber composite for sidewall of colored truck radial tire

A radial tire and rubber composition technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of flex fatigue resistance, reinforcement performance, and the inability to bring aesthetic enjoyment to people, and achieve excellent Flex fatigue resistance, bright color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

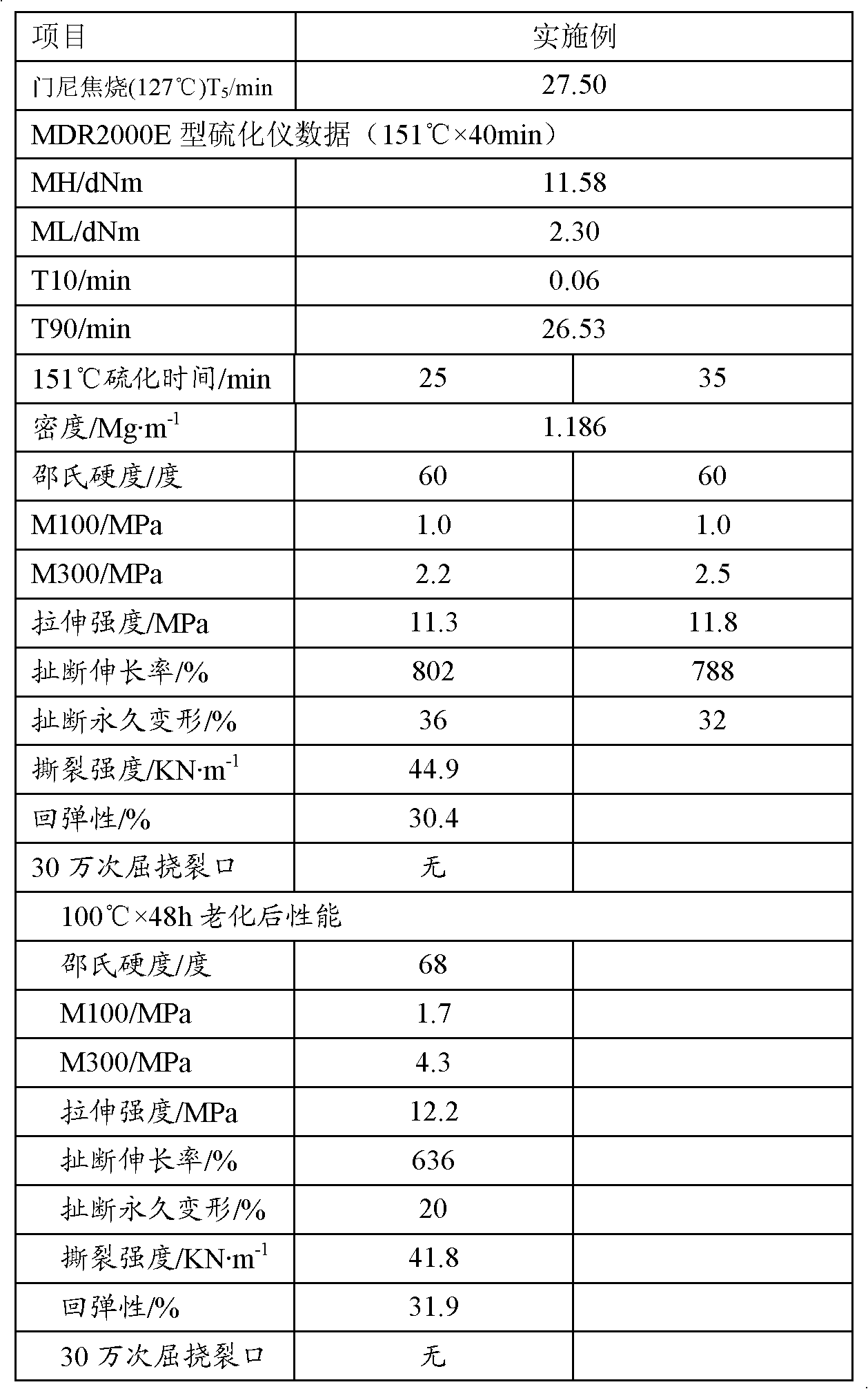

Examples

Embodiment Construction

[0014] The natural rubber in the base rubber of the rubber composition for sidewalls of colored radial truck tires of the present invention may be any general natural rubber, and may be used alone or in combination, regardless of origin. As the natural rubber, natural rubbers of grades such as RSS#3 and TSR are suitably used, for example. By weight (mass) ratio, based on 100 parts of the base rubber, the content of the natural rubber in the base rubber is preferably 30 parts or more. This is because when the content of natural rubber is less than 30 parts, the breaking strength of the rubber decreases. In addition, the content of natural rubber in the base rubber is preferably less than 70 parts, and when it exceeds 70 parts, the flex fatigue resistance of the rubber composition for sidewall tends to decrease. The content of natural rubber is more preferably 60 parts or less.

[0015] Halogenated butyl rubber (rubber) can improve the flex crack resistance and anti-aging perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com