Acrylamide ultrahigh molecular weight polymerization reaction initiator

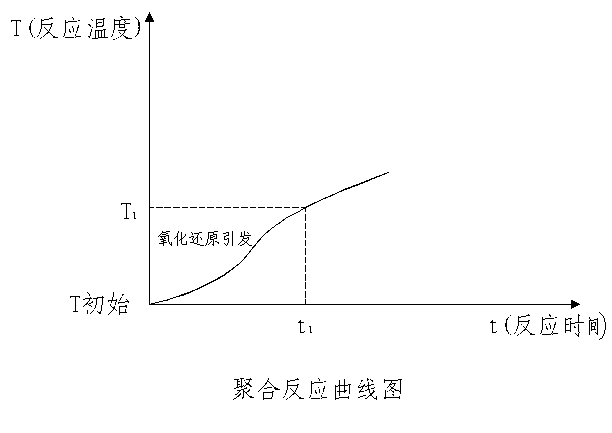

An ultra-high molecular weight, polymerization reaction technology, applied in the field of special composite initiators, can solve the problems of speeding up the polymerization reaction, difficult to control, non-reaction, and high reaction activation energy, and achieves good product solubility, little influence on molecular weight, and uniform polymerization reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

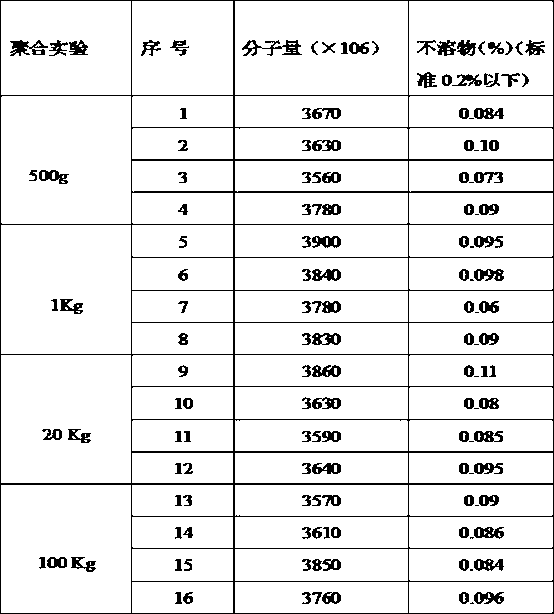

Examples

Embodiment 1

[0028] The acrylamide ultra-high molecular weight polymerization initiator of the present invention is composed of methyl isobutyl ketone, 4-heptanone, dimethylformamide, azobisisoheptanonitrile, azobisisobutyronitrile, azobisisobutyronitrile Dimethyl butyrate; the mass parts of each component are: 20 parts of methyl isobutyl ketone, 10 parts of 4-heptanone, 3 parts of dimethylformamide, 10 parts of azobisisoheptanonitrile, azo 3 parts of diisobutyronitrile, 10 parts of dimethyl azobisisobutyrate;

[0029] Its preparation method is as follows:

[0030] a. First, mix methyl isobutyl ketone, 4-heptanone, and dimethylformamide, and stir evenly at a temperature of 25-30°C;

[0031] b. Add dimethyl azobisisobutyrate and azobisisobutyronitrile to the mixed solution prepared in step a, and stir until fully dissolved while keeping the temperature not higher than 35°C;

[0032] c. Add azobisisoheptanonitrile to the mixed solution prepared in step b, and stir until completely disso...

Embodiment 2

[0034] The acrylamide ultra-high molecular weight polymerization initiator of the present invention is prepared from the following components in parts by mass: 50 parts of methyl isobutyl ketone, 40 parts of 4-heptanone, 10 parts of dimethylformamide, 30 parts of azobisisoheptanonitrile, 5 parts of azobisisobutyronitrile, 30 parts of dimethyl azobisisobutyrate;

[0035] Its preparation method is with embodiment 1.

Embodiment 3

[0037] The acrylamide ultra-high molecular weight polymerization initiator of the present invention is prepared from the following components in parts by mass: 30 parts of methyl isobutyl ketone, 15 parts of 4-heptanone, 3 parts of dimethylformamide, 15 parts of azobisisoheptanonitrile, 3 parts of azobisisobutyronitrile, 15 parts of dimethyl azobisisobutyrate;

[0038] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com