Manufacture method of dielectric substrate and metamaterial

A dielectric substrate and gel technology, applied in the field of metamaterials, can solve the problems of non-uniform distribution of the dielectric constant of the dielectric substrate, the dielectric substrate does not have the electromagnetic modulation function, etc., and achieve the effect of flexible design and extended function application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a dielectric substrate, comprising the following steps:

[0032] a. Using ethyl orthosilicate as the silicon source, take 104 grams of ethyl orthosilicate, 31.5 grams of water, and 92-460 grams of ethanol and mix evenly. The molar ratio is equivalent to ethyl orthosilicate: water: ethanol is 1: 3.5 : 4-20, obtain silica sol;

[0033] b. Pour the above-mentioned silica sol into a mold. The shape of the mold can be arbitrarily designed according to the application requirements of the dielectric substrate. In this embodiment, a flat plate is used, and ammonia water with a concentration of 0.35mol / L is added dropwise to adjust the pH value. To 2.5-3.5, stand still, make the silica sol age and form a gel;

[0034] c. Use ethanol or acetone as a replacement agent to replace the water in the gel, and obtain a gel block after demoulding;

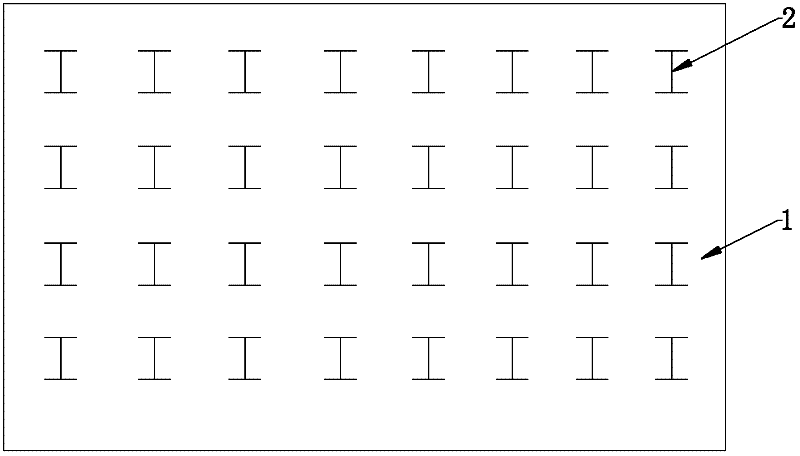

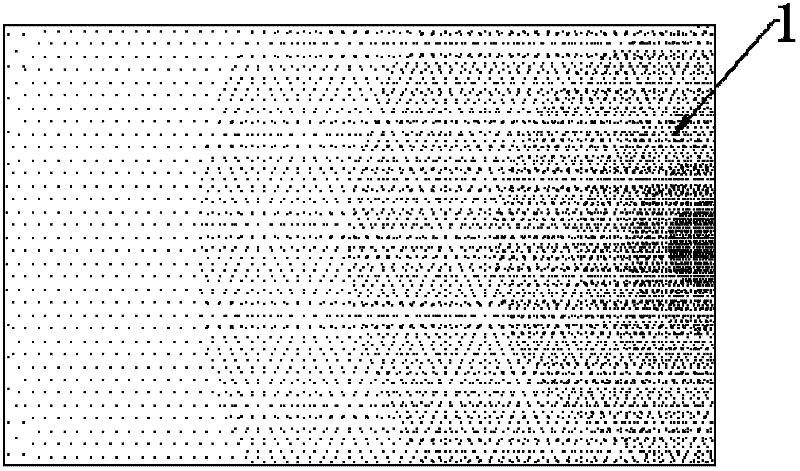

[0035] d. The above-mentioned gel block is heated non-uniformly with a single thermal radiation infrared lamp. In t...

Embodiment 2

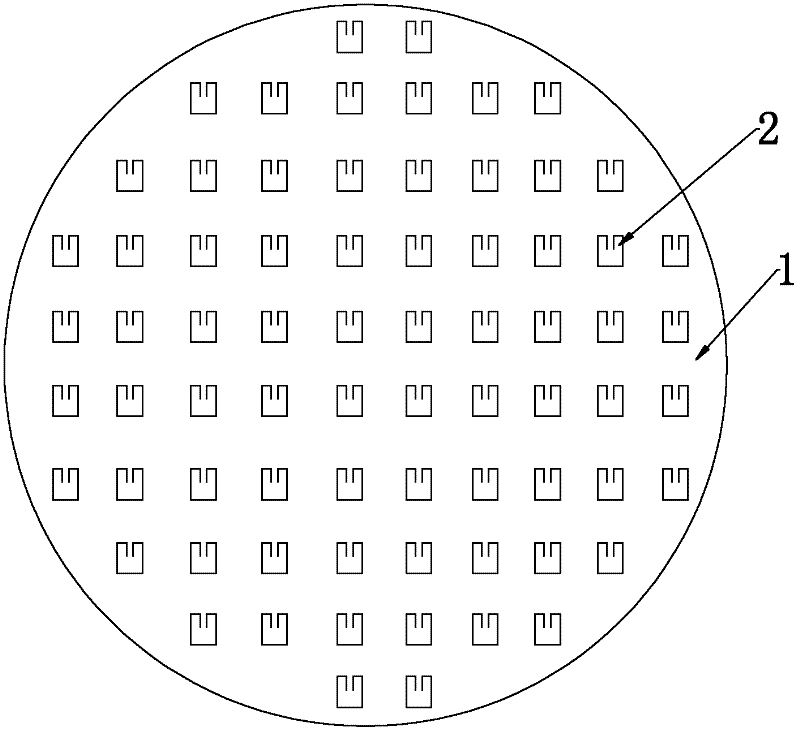

[0038] A method for preparing a dielectric substrate, comprising the following steps:

[0039] a. Methyl orthosilicate: water: ethanol: HCl according to 1: 3.5: 8: 8.4 × 10 -4 The molar ratio is mixed to obtain a mixed solution. In order to increase the porosity, formamide and ethylene glycol can be added as a drying control agent, and a constant temperature water bath is kept at 60°C for 2 hours to obtain a silica sol;

[0040] b. Place a layer of organic fiber cloth on the bottom of a mould. The shape of the mold can be arbitrarily designed according to the application requirements of the dielectric substrate. Drop in hydrochloric acid with a mass fraction of 1.5%, adjust the pH value to 11-12, and let it stand to age the silica sol to form a gel;

[0041] c. Using ethanol or acetone as a displacing agent, remove the water in the gel, use the surface modifier trimethylchlorosilane to hydrophobically treat the gel, and obtain a gel block after demoulding;

[0042] d. The ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com