Jar frame for truck

A battery and truck technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as unstable sliding, high material costs, loud noise, etc., and achieve overall function optimization, light structure, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

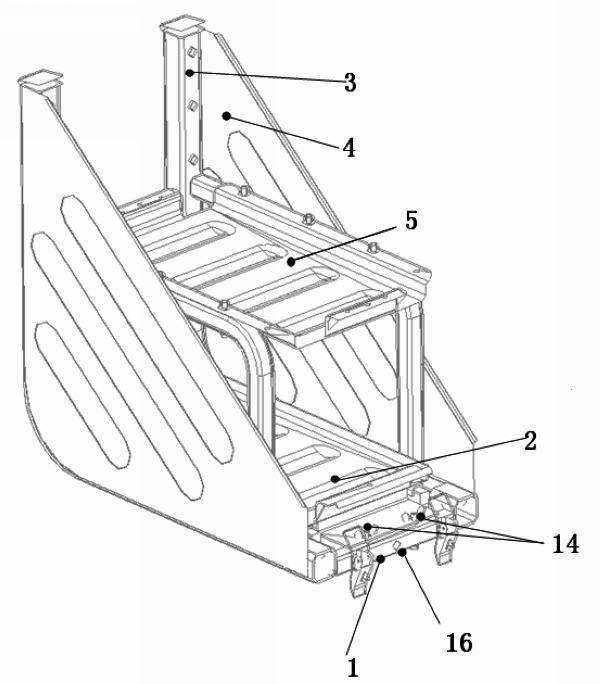

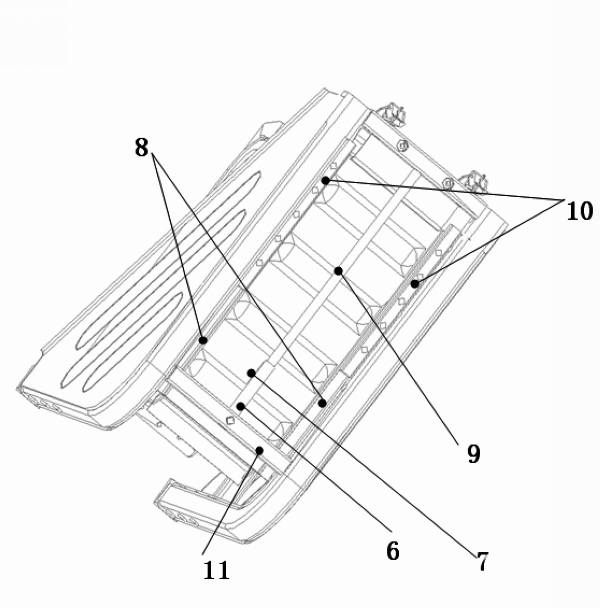

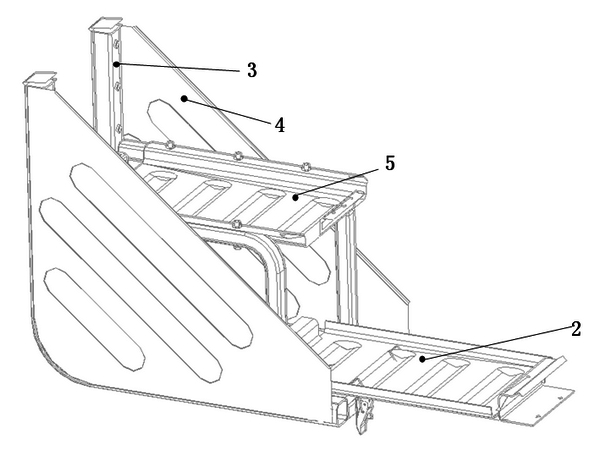

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the upper frame 5 is fixed on the main frame 3 with connecting bolts; the side plate is welded on the main frame 3; the ball slideway 10 of the slideway mechanism is welded on the main frame 3, and the ball made of 20*20 square steel Stepped holes are evenly distributed on the type slideway 10, and the balls 12 are installed in the holes through the plugs 13. There is a gap of 0.5 mm between the balls 12 and the bolt plugs 13 to facilitate the rolling of the balls 12. The holes for placing the balls 12 are processed by numerical control. To ensure its smoothness, the movable bottom plate 2 that can slide on the ball-type slideway 10 is in direct contact with the balls 12, and the movable bottom plate 2 is fixed on the front fixing bracket 1 of the battery frame by bolts 14 to prevent the movable bottom plate 2 from sliding back and forth, and the movable The bottom plate 2 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com