Multiple-mould changing system in parallel arrangement

A technology for molds and stamping molds, which is applied in the field of parallel mold change systems for multiple sets of molds. It can solve the problems of insufficient site space, inability to expand, and large space occupation, and achieve the effects of reducing process arrangements, saving handling work, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

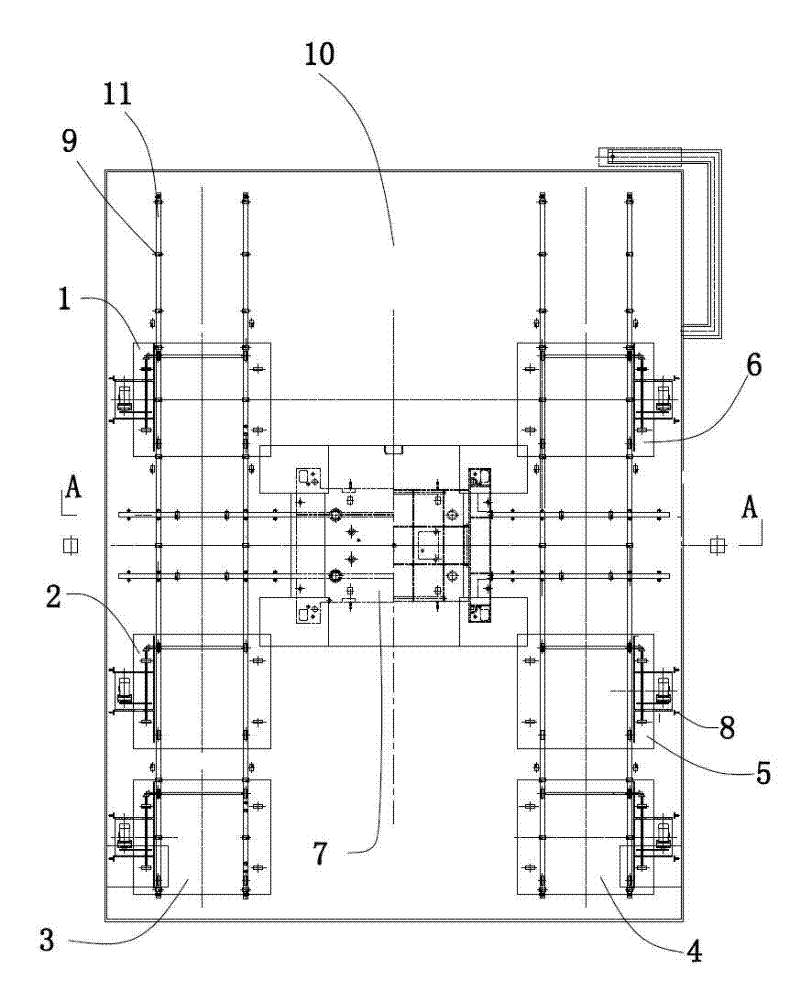

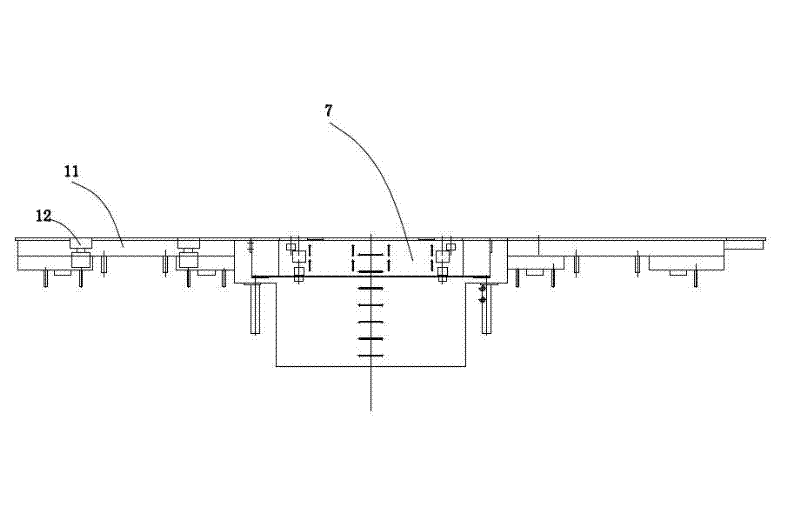

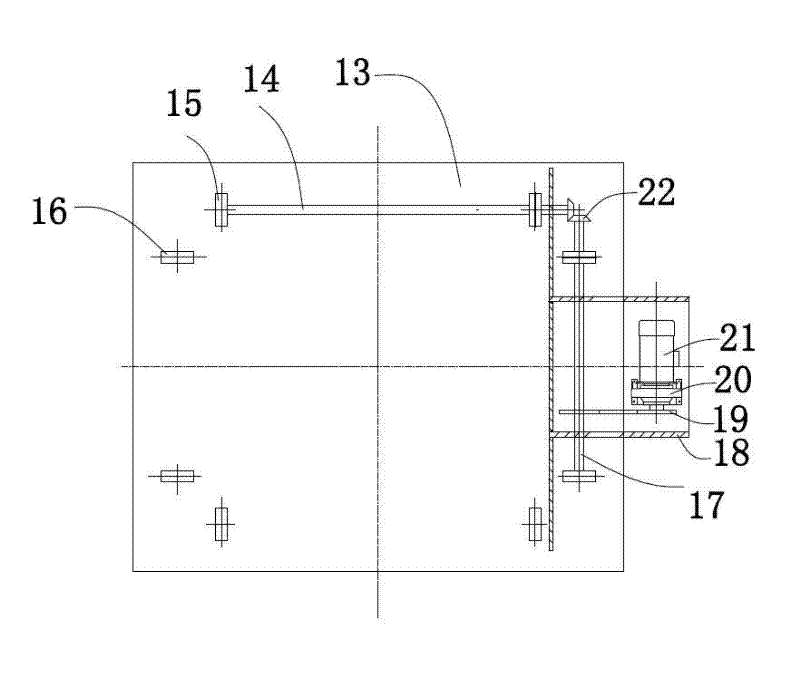

[0029] Embodiment: a kind of mold changing system of multiple sets of molds for body hemming machine (see attached figure 1 attached figure 2 ), which is set on the base 10 as a whole, including stamping die device, replacement mechanism and control system, and the stamping die device includes workbench 13 (see attached image 3 ) and the mold fixed on the workbench, the lower surface of the workbench is provided with four longitudinal wheels 15 and four transverse wheels 16, the diameter of the transverse wheels is smaller than the diameter of the longitudinal wheels, and the two longitudinal wheels pass through the longitudinal driving rod 14 connection, the two horizontal wheels are connected by a vertically arranged horizontal drive rod 17, the longitudinal drive rod and the horizontal drive rod are connected by a pair of meshing bevel gears 22, the drive motor 21 is fixed on the side of the table, and the drive motor 21 passes through the reducer 20 and transmission bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com