Multifunctional environment-friendly coating robot

A robotic and multi-functional technology, applied to the device for coating liquid on the surface, coating, etc., to solve the problem of easy-to-dry conjunctiva, improve work efficiency, and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

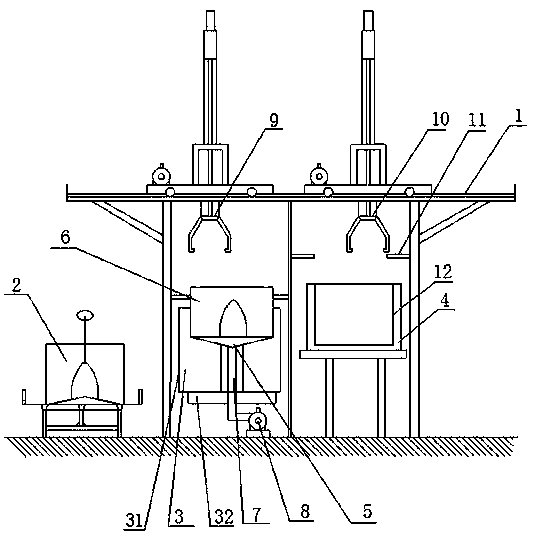

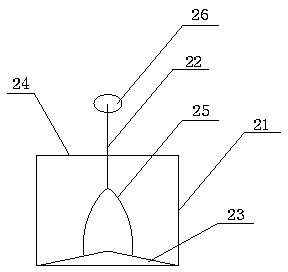

[0014] Such as figure 1 As shown, a multifunctional environment-friendly painting robot includes a portal frame 1 formed by a beam and a plurality of uprights. Below the beam of the portal frame 1, a dipping basket 2, a dipping cylinder 3, and a centrifugal Machine 4, dipping cylinder 3 comprises cylinder body 31 and lifting mechanism 32, and this lifting mechanism 32 is fixedly connected with cylinder body 31 and is used for controlling the lifting of dipping cylinder 3; A centrifugal drum 6 is installed on the centrifugal seat 5, the bottom of the centrifugal seat 5 is connected with a transmission shaft 7 that runs through the impregnation cylinder 3 longitudinally, and the other end of the transmission shaft 7 is connected with a centrifugal drive device 8; the impregnation basket 2 and the centrifugal The drum 6 is concentric; the first automatic manipulator 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com