HCl dehydration and purification method suitable for synthesis of trichlorosilane

A technology of trichlorosilane and purification method, which is applied in the direction of silicon halide compound and halosilane, etc., which can solve the problems of high dehydration cost of molecular sieve, increase of production cost, increase of silicon powder unit consumption, etc., and achieve inhibition of by-product tetrachloride Effects of silicon formation, yield improvement, and avoidance of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

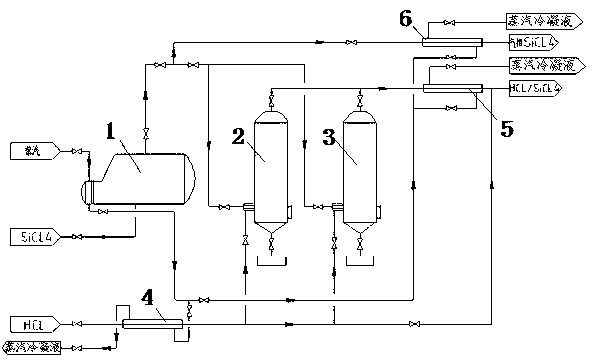

[0038] Such as figure 1 As shown, the device includes silicon tetrachloride vaporizer 1, silicon dioxide separator a 2 and silicon dioxide separator b 3, HCl heating jacket 4, HCl / SiCl 4 Mixed gas heating sleeve 5 and gas phase silicon tetrachloride heating sleeve 6 .

[0039] A kind of HCl dehydration purification technology applicable to the synthesis of trichlorosilane, comprising the following steps:

[0040] 1) Vaporize silicon tetrachloride in silicon tetrachloride vaporizer 1 with steam above 0.9Mpa, and vaporize to above 150°C.

[0041] 2) For HCl whose temperature is lower than 140°C, first heat the HCl to above 140°C through a heating sleeve 4, and the heating sleeve uses the steam condensate after heat exchange of the silicon tetrachloride vaporizer to heat, making full use of energy .

[0042] 3) A certain amount of gaseous silicon tetrachloride and HCl heated to above 140°C through the heating sleeve 4 enter the silica separator a 2 and two The silica separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com