Calcium-complex starch-based microporous haemostatic material, and preparation method and application thereof

A hemostatic material, starch-based technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of difficult in vivo degradation, poor biocompatibility, and high production cost, and achieve good biocompatibility, low cost, and easy preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Preparation method of starch-based microporous hemostatic material

[0063] The preparation method of the starch-based microporous hemostatic material of the present invention comprises the following steps:

[0064] (1) Preparation of microporous starch

[0065] Add starch and enzymes to phosphate buffer, stir at 45-80°C and pH 5-7 to carry out enzymolysis reaction, centrifuge after 4-15 hours, and dry to obtain microporous starch; wherein,

[0066] The mass ratio of the starch and the enzyme is 1: (0.01-0.2);

[0067] The mass volume ratio of the total amount of the starch and enzyme to the phosphate buffer is 100g: (250-1000) ml;

[0068] (2) Carboxymethylation of microporous starch

[0069] Dissolve monochloroacetic acid in ethanol, add sodium hydroxide solution to pH 6.5-7, mix it into the microporous starch prepared in the step (1) of dissolving with ethanol, stir well, and put it under the condition of 50-80°C Continue to stir and keep warm to react for 4-8 ho...

Embodiment 1

[0110] First, weigh 100g of tapioca starch and 1g of glucoamylase, add them into 250ml of phosphate buffer solution with pH=5, stir evenly, carry out hydrolysis reaction at 45°C for 4 hours, centrifuge at 4000r / min, and Vacuum dried for 24 hours to obtain microporous starch.

[0111] Dissolve 8g of monochloroacetic acid in ethanol, adjust it to neutral with 0.3mol / L sodium hydroxide solution, mix it into the above-prepared microporous starch dissolved in 80g of ethanol, stir well and move it into a constant temperature tank. Under the condition of 50° C., the reaction was carried out with continuous stirring and heat preservation at 45 r / min. After 4 hours, the reaction was completed, and acetic acid was added to neutralize the pH to 6.5, filtered, washed 3 times with ethanol, and dried for 24 hours to obtain carboxymethyl microporous starch.

[0112] Finally, add the carboxymethylated microporous starch obtained in the above reaction into a saturated calcium chloride solutio...

Embodiment 2~4

[0114] Examples 2-4 Repeat the experimental steps of Example 1, the difference lies in some experimental conditions, as shown in Table 1-3.

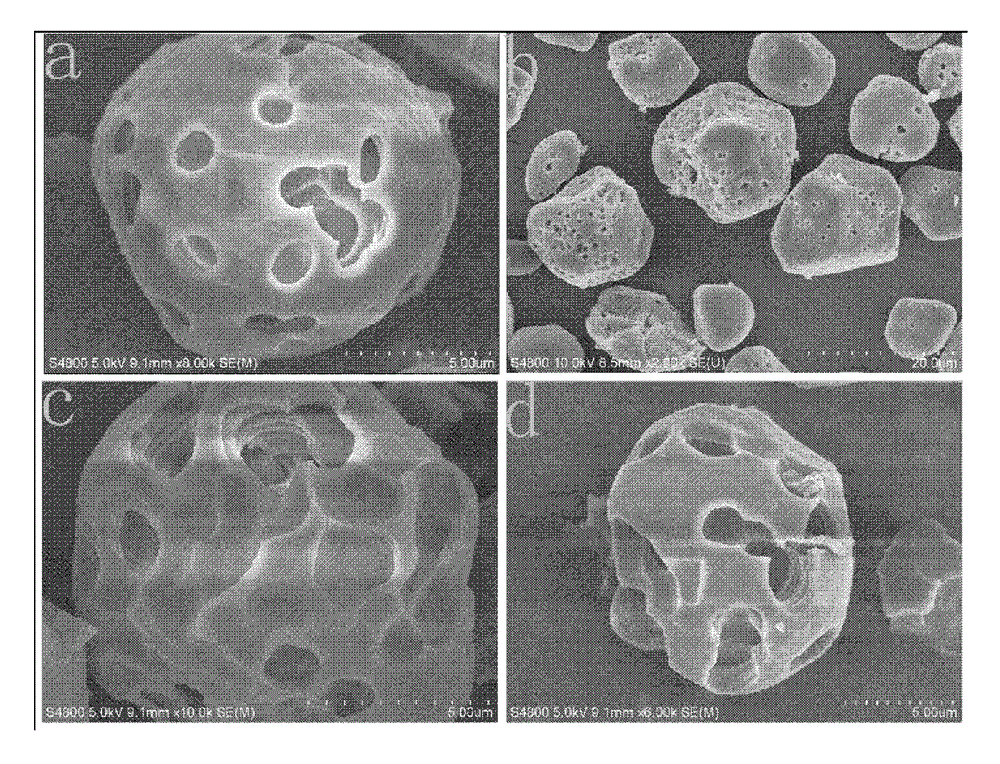

[0115] Adopt scanning electron microscope (SEM) to observe respectively the pure microporous starch that embodiment 1 prepares (see appendix figure 2 (a) and (b)) and the microscopic appearance of the calcium complex type microporous starch prepared by embodiment 2, embodiment 4 (see attached figure 2 (c) and 2(d)). It can be seen from the figure that the diameter of the prepared calcium-complexed microporous starch particles is about 10-20 μm, and the surface is covered with small pores with a diameter of about 1-5 μm, and the pores are embedded from the surface to the center to form a cavity.

[0116] The average pore size of the calcium-complexed microporous starch prepared in Examples 1-4 is shown in Table 4. It can be seen from Table 4 that with the prolongation of the enzymatic hydrolysis reaction time, the average pore size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com