Process for manufacturing printed circuit boards having high-frequency and low-frequency mixed board structures

A technology of printed circuit board and manufacturing process, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit components, etc., can solve the problems of delamination and explosion, achieve the goal of reducing volume, saving cost, and improving product assembly density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

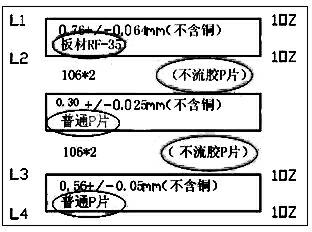

[0021] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0022] 1) Cutting material:

[0023] l When cutting the material, it is necessary to measure the thickness of the cutting substrate within the tolerance range to ensure that the cutting plate can meet the thickness requirements of the laminated plate;

[0024] l Cutting size: 605*300mm; material: IT158 and RF-35;

[0025] 2) Inner graphics:

[0026] l Make the inner layer graphics of high-frequency panels and low-frequency panels;

[0027] 3) Pressing

[0028] l Browning: browning of light board and core board, browning speed: 3.0~3.2m / min;

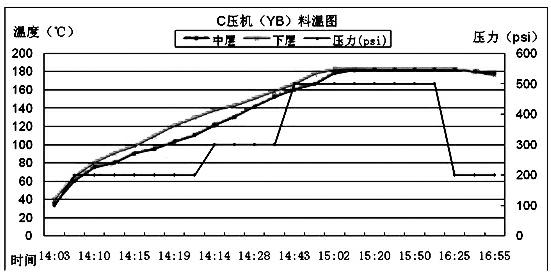

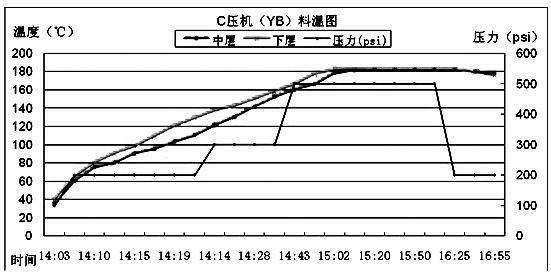

[0029] l Pressing: A. The hot pressing parameters are shown in Table 1: use the following parameters; kraft paper: 20 sheets (new) for each top and bottom;

[0030] B. When typesetting, pay attention to cleaning the PP powder on the copper surface of the step plate;

[0031] C. The number of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com