Thin film scandium-tungsten cathode and preparation method thereof

A tungsten cathode and cathode technology, which is applied in thermionic cathode manufacturing, electrical components, discharge tube/lamp parts, etc., can solve the problems of complex film forming process and poor controllability, and achieve uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

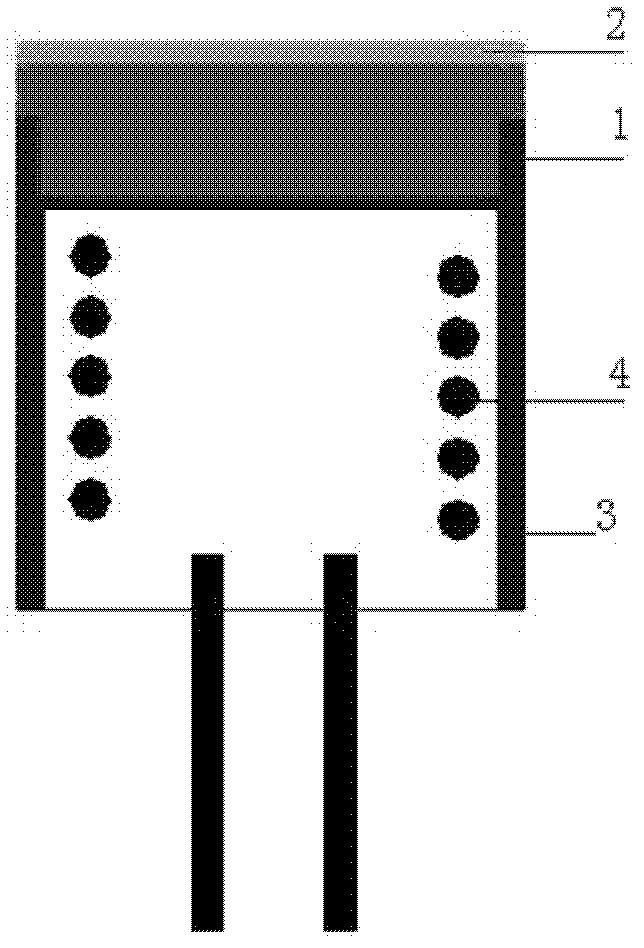

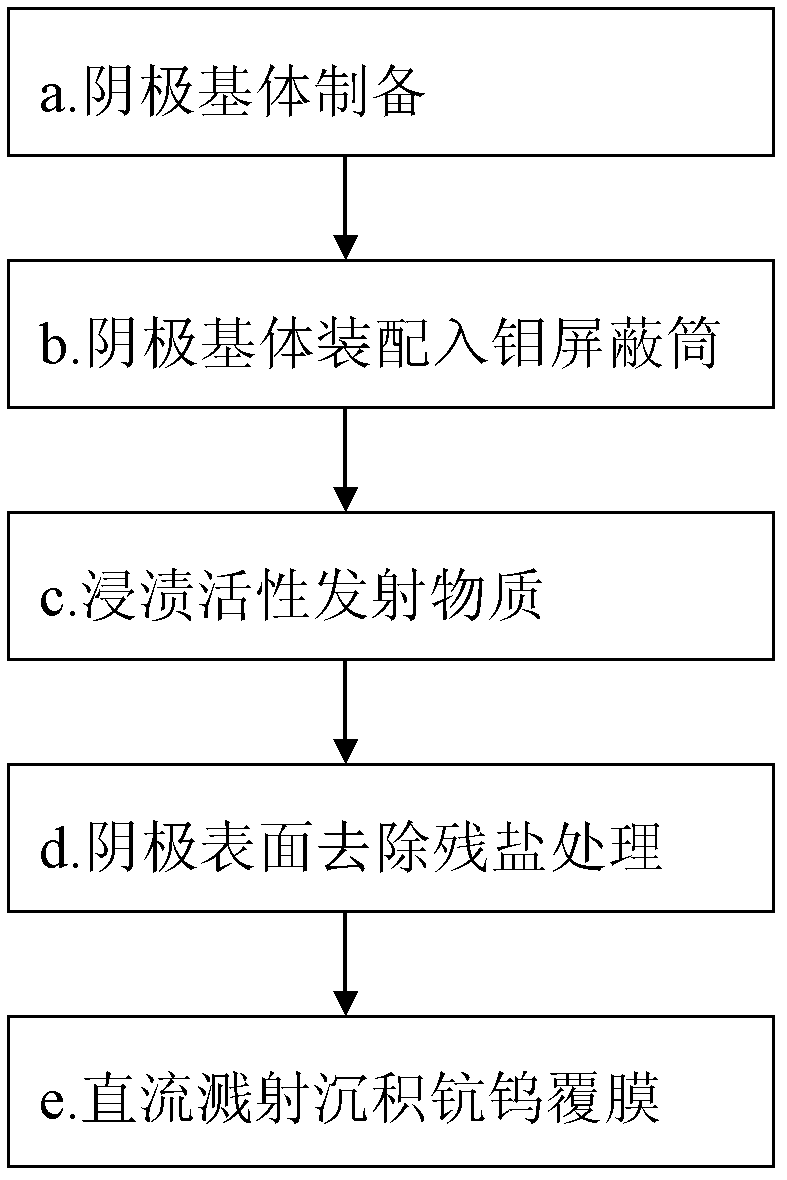

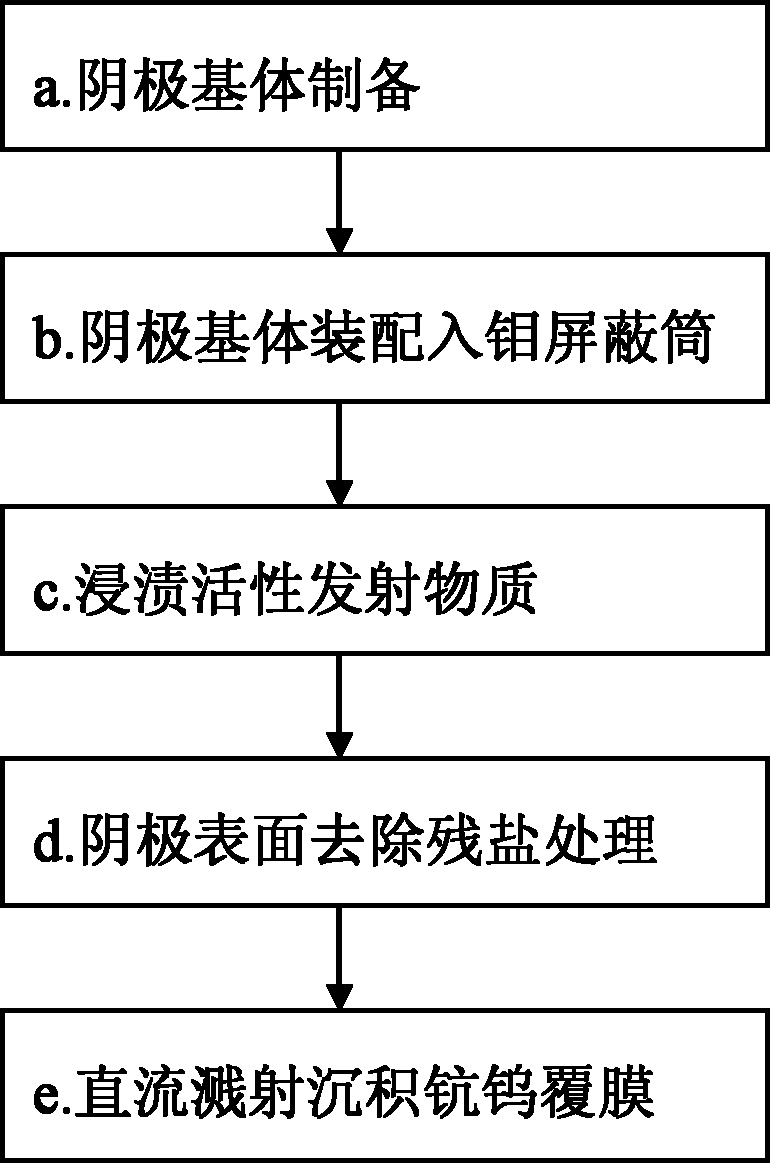

[0021] refer to figure 1 , showing a schematic diagram of the structure of a thin-film scandium-tungsten cathode, 1 in the figure shows the cathode substrate, which is a conventional porous tungsten substrate with aluminate added, and a scandium-tungsten coating film 2 is synthesized on the top surface of the surface, and the lower part is a molybdenum shielding cylinder 3. Inside the shielding cylinder is the thermal subassembly 4. refer to figure 2 , represents the process flow diagram of the thin-film scandium-tungsten cathode preparation method, and its specific implementation is operated according to the following steps:

[0022] a. Preparation of cathode substrate;

[0023] b. Assemble the cathode substrate and the molybdenum support cylinder;

[0024] c. The assembled cathode is impregnated with an active emission material, wherein the molar ratio of the active material is BaO: CaO: Al 2 o 3 =6:1:2;

[0025] d. Cathodic surface treatment to remove residual salt o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com