OTM (oxygen transport membrane)-integrated SOFC (solid oxide fuel cell)/AT (air turbine)/ST (steam turbine) composite power system with zero CO2 (carbon dioxide) emission

A compound power and zero-emission technology, applied in the direction of machines/engines, fuel cell additives, mechanical equipment, etc., can solve the problems of high and low energy consumption, achieve low energy consumption, reduce power consumption, and reduce useful work Effects of loss and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

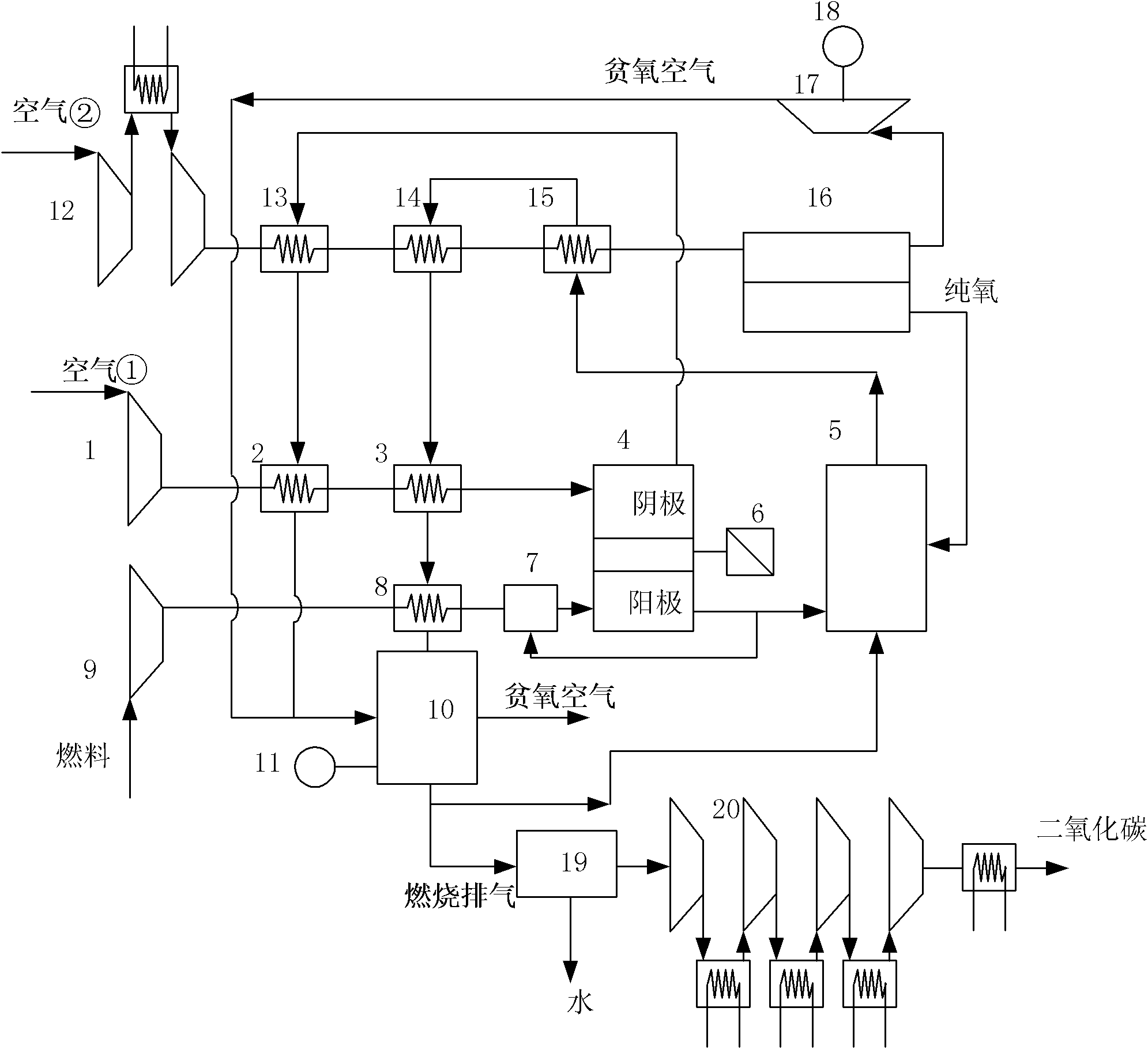

[0023] The present invention provides a CO with integrated OTM 2 The zero-emission SOFC / AT / ST composite power system, the present invention will be further described below through the description of the drawings and specific embodiments, wherein, AT is the abbreviation of air turbine, and ST is the abbreviation of steam turbine.

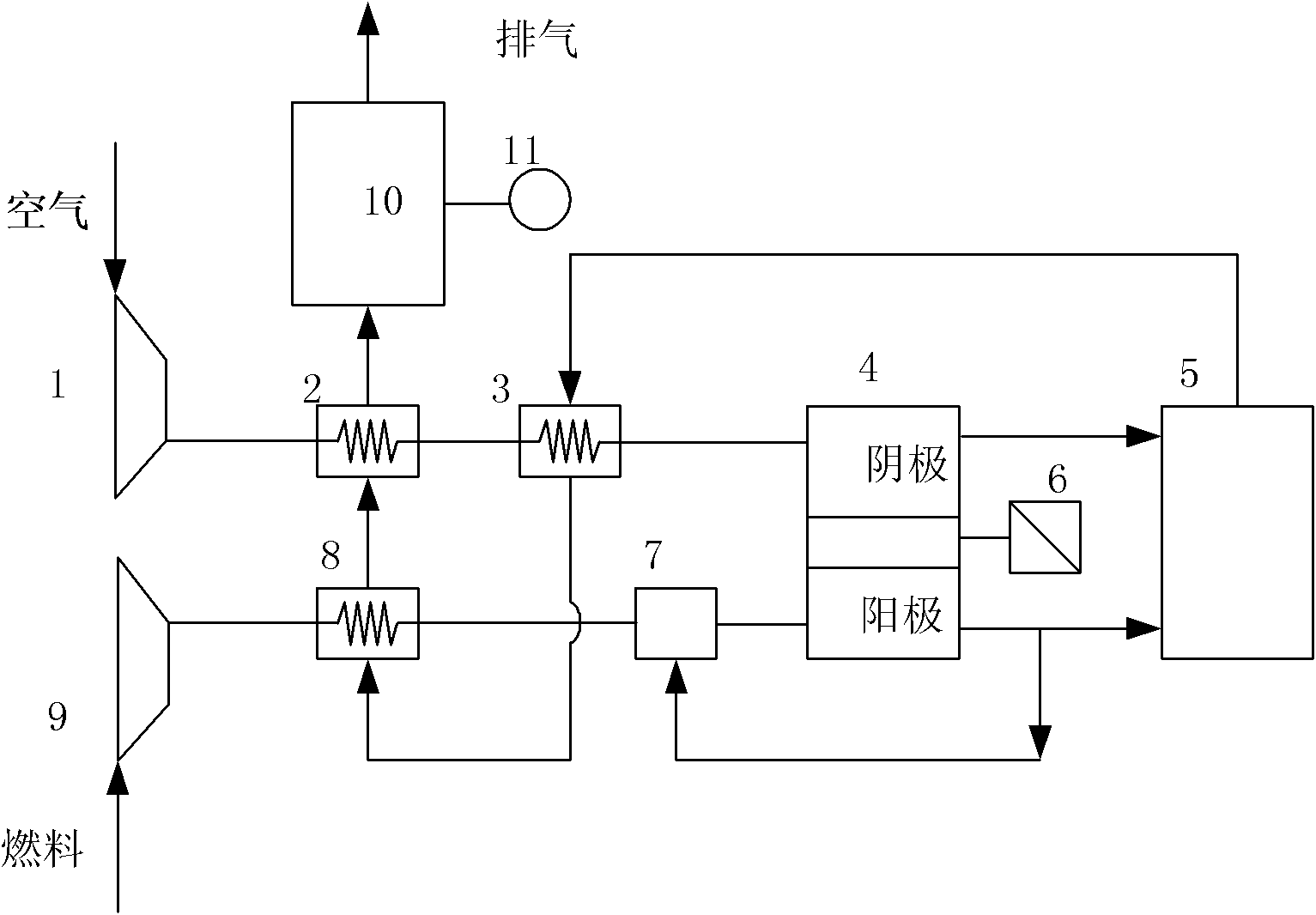

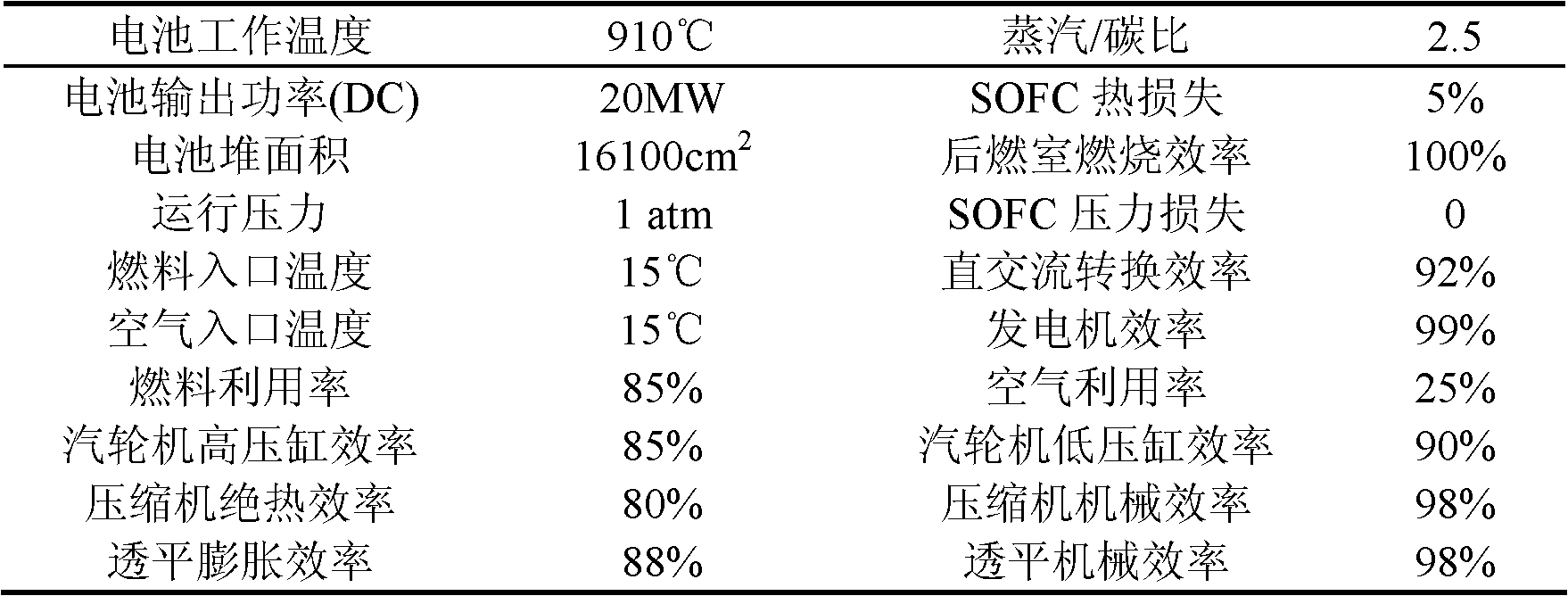

[0024] The benchmark system is a normal pressure system, and the compressor pressurizes the air and fuel only to overcome the pressure loss in the flow process. Its structure diagram is as follows: figure 1 Shown: After the air is compressed by the air compressor 1, it flows through the first heat exchanger 2 and the second heat exchanger 3 in turn, and enters the cathode of the SOFC cell stack 4, and the fuel is compressed by the fuel compressor 9 and passes through the third heat exchanger 8 After heat exchange, it enters the pre-reformer 7 and mixes and reforms with the recycled part of the anode exhaust gas, and then enters the anode of the SOFC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com