Steel wire mesh bent reinforced Z-shaped section concrete column and making method

A technology of steel wire mesh and concrete columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of weak earthquake resistance, poor integrity, poor thermal insulation performance, etc., to increase the use area, improve bearing capacity, prevent The effect of brittle shear failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

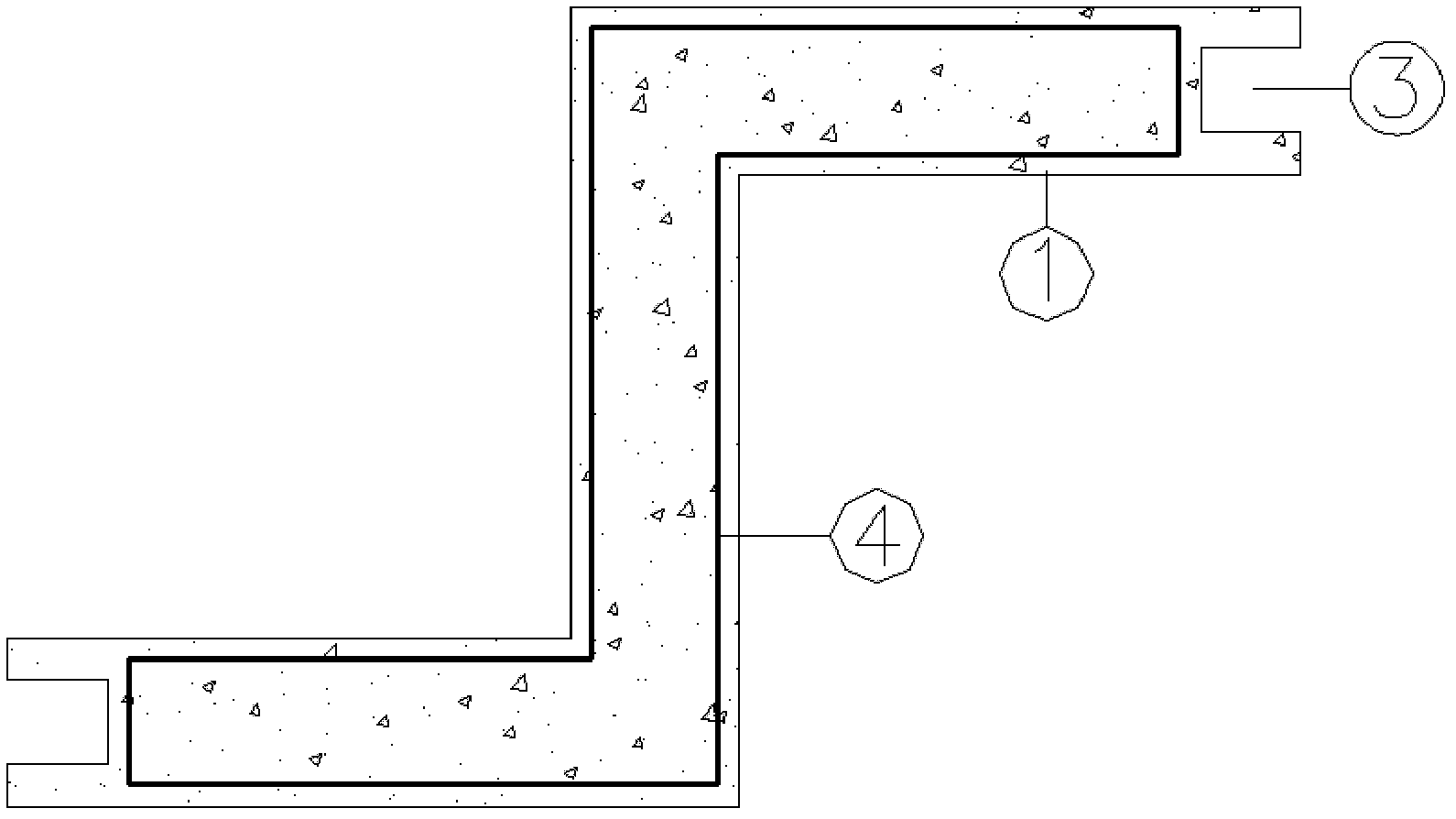

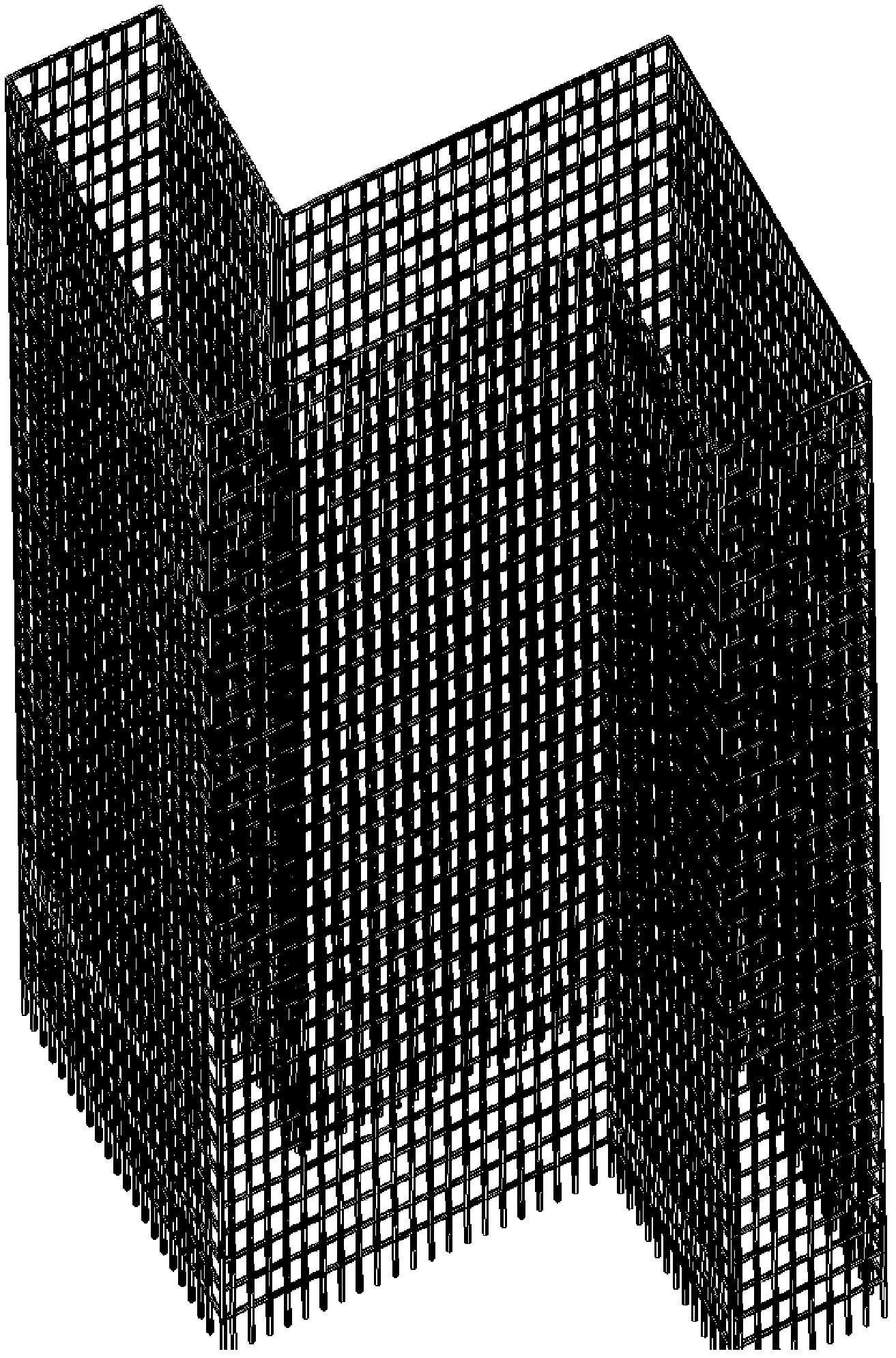

[0025] like Figure 1 to Figure 4 The steel wire mesh sheet bending forming type reinforced T-shaped concrete column is mainly composed of concrete 1, concave keyway 3 and T-shaped steel mesh skeleton 4; the column section is T-shaped, and the T-shaped concrete column along the T-shaped steel wire mesh skeleton 4 is embedded in the periphery of the T-shaped concrete column, and the shape of the T-shaped steel mesh skeleton 4 is a closed and hollow T shape; The concave keyway 3 used for connecting with the light insulation wall; the T-shaped steel wire mesh frame 4 is formed by bending the steel wire mesh 2 during prefabrication.

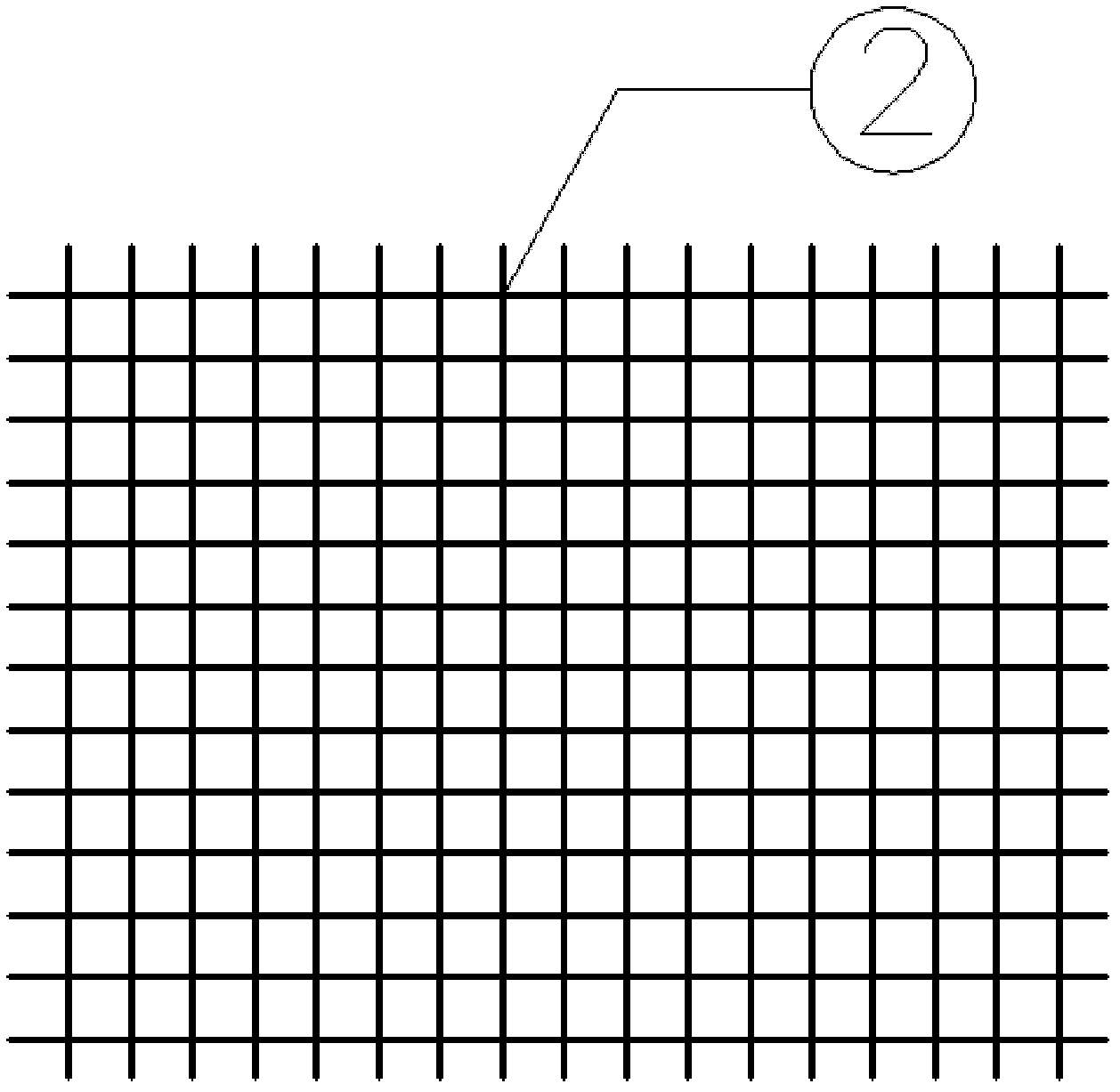

[0026] The steel wire mesh 2 is a square grid spliced by horizontal and vertical 8# lead wires or galvanized iron wires with a diameter of 4mm. The length of one side of the grid is greater than the particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com