As-cast bainite vermicular graphite cast iron cylinder jacket and its preparation method

A technology of vermicular graphite cast iron and bainite, which is applied in the field of as-cast bainite vermicular graphite cast iron cylinder liner, can solve the problem that the explosion pressure increases, and the alloy bainite is difficult to meet the working requirements and design life of high-end engines. Further improvement and other issues to achieve the effect of improved reliability, high strength, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

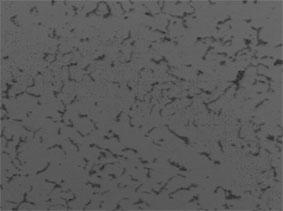

Embodiment 1

[0027] The chemical components are prepared according to the following weight percentages: 3.71% carbon, 1.23% silicon, 0.22% manganese, 0.075% phosphorus, 0.020% sulfur, 0.89% copper, 0.63% molybdenum, 0.15% titanium, and the balance is Fe; use an intermediate frequency induction furnace For smelting ingredients, control the temperature of the molten iron to 1540°C; then transfer the molten iron to a pouring furnace with a temperature of 1520°C; Creeping occurs, and the addition of vermiser and SiFe75 inoculant is 0.9% of the weight of molten iron; pour the vermisified molten iron into a centrifugal casting mold, and adopt the conventional process of centrifugal casting of metal mold wet paint to produce cylinder liners Castings; control the casting temperature at 900°C, then rapidly cool the castings for 1.5 minutes to lower the casting temperature to 500°C; transfer the castings to an incubator for slow cooling for 2 hours; then temper at 520°C for 2.5 hours to obtain a cyli...

Embodiment 2

[0029] The chemical components are prepared according to the following weight percentages: 3.82% carbon, 1.26% silicon, 0.32% manganese, 0.09% phosphorus, 0.025% sulfur, 1.05% copper, 0.99% molybdenum, 0.09% titanium, and the balance is Fe; use a medium frequency induction furnace For smelting ingredients, control the molten iron temperature to 1580°C; then transfer the molten iron to a pouring furnace with a temperature of 1510°C; Creeping occurs, and the addition of vermiser and SiFe75 inoculant is 0.9% of the weight of molten iron; pour the vermisified molten iron into a centrifugal casting mold, and adopt the conventional process of centrifugal casting of metal mold wet paint to produce cylinder liners Castings; control the casting temperature at 850°C, then rapidly cool the castings for 2 minutes to lower the casting temperature to 500°C; transfer the castings to an incubator for slow cooling for 1.5 hours; then hold at 500°C for 2 hours for tempering to obtain the finishe...

Embodiment 3

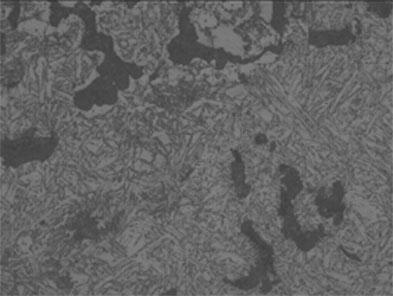

[0031] The chemical components are prepared according to the following weight percentages: 3.88% carbon, 1.53% silicon, 0.42% manganese, 0.075% phosphorus, 0.022% sulfur, 1.15% copper, 1.15% molybdenum, 0.11% titanium, and the balance is Fe; use an intermediate frequency induction furnace For smelting ingredients, control the temperature of the molten iron to 1560°C; then transfer the molten iron to a pouring furnace with a temperature of 1505°C; Creeping occurs, and the addition of vermiser and SiFe75 inoculant is 0.9% of the weight of molten iron; pour the vermisified molten iron into a centrifugal casting mold, and adopt the conventional process of centrifugal casting of metal mold wet paint to produce cylinder liners Castings; control the casting temperature at 750°C, then rapidly cool the castings for 1.5min to lower the casting temperature to 400°C; transfer the castings to an incubator for slow cooling for 1.5h; then hold at 550°C for 2h for tempering to obtain a cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com