Novel thermal insulation fireproof wall calcium silicate board and preparation method thereof

A technology of thermal insulation and calcium silicate board, which is applied in the field of boards, can solve problems such as inability to achieve practical performance and low thermal conductivity, and achieve strong elasticity and toughness, good fire performance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail:

[0024] Preparation of 1000 kg of calcium silicate board for new thermal insulation firewall body:

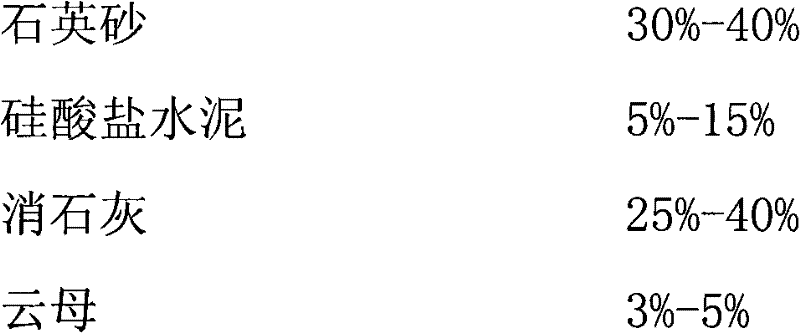

[0025] Step 1: Prepare raw materials according to the following components and their mass percentages: 350 kg of quartz sand, 150 kg of Portland cement, 250 kg of slaked lime, 50 kg of mica, 130 kg of vermiculite, and 70 kg of wood pulp fiber;

[0026] Step 2: Shredding: put the paper blocks into the shredder with water, set the shredding time according to different types of paper, control the shredded paper concentration within 10%, and then pump the shredded pulp into the paper storage pool , start the refiner, the current is controlled at 150-170A, and the degree of pulp debonding is controlled at 30-35SR. , the temperature and weight are controlled at 4-5g, and finally the crushed pulp is stored in the pulp pool for later use;

[0027] Step 3: Pulping: according to the propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com