Method for preparing baking-free load-bearing tile by curing desulfurization waste residues with semidry process at normal temperature

A semi-dry desulfurization and room temperature curing technology, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as unverified long-term durability of building mortar, disadvantageous mass processing and utilization of desulfurization slag, and application risks that cannot be ignored. The effect of short maintenance time, small investment and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

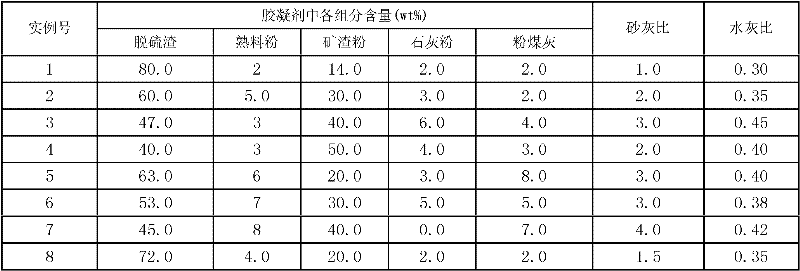

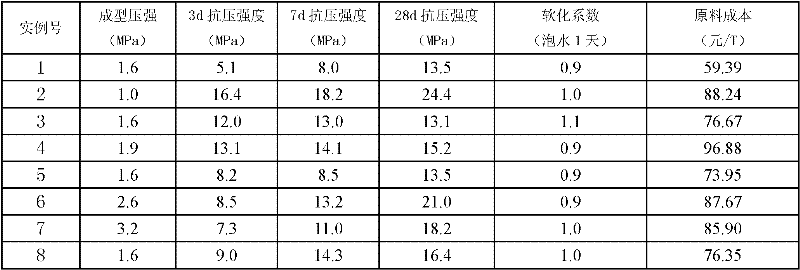

[0020] The present invention will be further described in detail below in conjunction with specific experimental examples.

[0021] First, according to the mass percentage of each raw material, they are 40-80wt% desulfurization slag, 14-50wt% slag powder, 2-8wt% clinker powder, 2-6wt% lime powder, 2-8wt% The ratio of fly ash is mixed to prepare the gelling agent. Among them, the desulfurization slag is off-white to light gray-yellow fine powder, with good dispersibility and fluidity, and meets the following conditions: the average particle size is 4-10um, and the specific surface area is 2-10m 2 / g, its composition is: the mass percent content is the CaO of 40-50%, the SO of 8-16% 3 , 10-18% SO 2 , 1-3% MgO, 1-2% TFe, 0.2-1.0% SiO 2 , 0.4-0.6% Al 2 o 3 , 1-5% K 2 O, 0.1-0.5% Na 2 O, 1-5% chloride, 15-25% loss on ignition, its radionuclide content complies with GB6566-2010 building main material nuclide content index, namely I Ra ≤1.0B q / Kg, I γ ≤1.0B q / Kg (testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com