Broad-spectrum bio-energizer for industrial wastewater treatment and preparation method thereof

A bio-promoting agent, industrial wastewater technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. single problem, to achieve the effect of improving the utilization rate of nutrients, improving the recovery ability, and speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First prepare the following ingredients:

[0033] 1) 5kg protease

[0034] 2) 11kg of fulvic acid

[0035] 3) 5kg of 75% phosphoric acid (phosphorus element 1.18kg)

[0036] 4) 1.15kg of trace element salts, specifically: Fe(NO 3 ) 3 9H 2 O 800g (Iron 110g), Mn(NO 3 ) 2 4H 2 O 250g (manganese 55g), ZnCO 3 100g (zinc 52g).

[0037] 5) 1.5kg cytokinin

[0038] 6) 15.5kg urea (nitrogen 7.54kg)

[0039] 7) 60.85 kg of water.

[0040] Mix 1) protease with 7) water, add 2), 3), 4), 5) and 6) in sequence, and then continue stirring for 4 hours.

Embodiment 2

[0042] First prepare the following ingredients:

[0043] 1) 4kg protease, 1kg cellulase

[0044] 2) 10kg of humic acid, 1kg of amino acid (0.25kg each of lysine, phenylalanine, threonine and isoleucine, or mixed in any ratio)

[0045] 3) 4.4kg of 85% phosphoric acid (phosphorus element 1.25kg)

[0046] 4) 1.05kg of trace element salts, specifically: Fe(NO 3 ) 3 9H 2 O 720g (iron 100g), Mn (NO 3 ) 2 4H 2 O 230g (manganese 51g), ZnCO 3 100g (zinc 52g).

[0047] 5) 1.5kg cytokinin

[0048] 6) 10kg urea, 14.5kg ammonium nitrate ((nitrogen 9.94kg)

[0049] 7) 52.55 kg of water.

[0050] Mix 1) and 7), add 2), 3), 4), 5), and 6) in sequence, and then continue stirring for 4 hours.

Embodiment 3

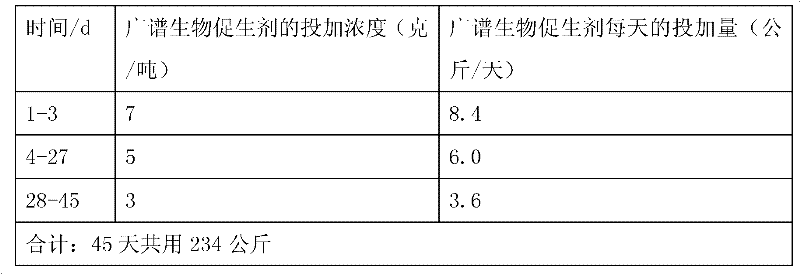

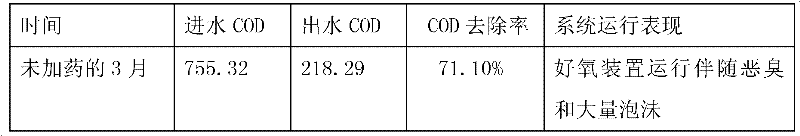

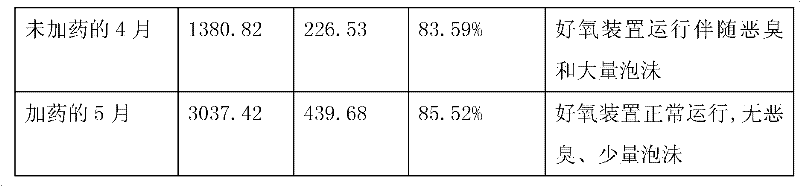

[0052] The wastewater treatment volume of the ethylene glycol plant of a petrochemical company is 2400m 3 / d, the influent COD is 2000-3500mg / L, and the biochemical section adopts hydrolytic acidification + contact oxidation process. Wastewater contains a lot of sulfonic acid surfactants. When the concentration of such organic matter is high, it is not only difficult to be decomposed by microorganisms, but also inhibits the activity of microorganisms. Moreover, a large amount of foam is generated during aeration, which affects the dissolved oxygen content of the water body. Partially anaerobic, producing foul odor, making it difficult for the biochemical system to operate normally. During the same period, the scale of production expanded, and the amount of wastewater treated by the company doubled on the original basis. However, due to the limitation of the factory site, it was impossible to add another set of treatment devices. However, if chemical oxidation or other methods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com