Anti-explosion and anti-impact bumper system of remote-control rail flat car

A bumper and anti-shock technology, which is applied in the direction of railway vehicle wheel guards/buffers, railway car body parts, transportation and packaging, etc., and can solve problems such as electrical equipment leakage or sparks, leakage of dangerous goods, fire or explosion, etc. Achieve the effects of reducing the loss of on-board cargo, reliable operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

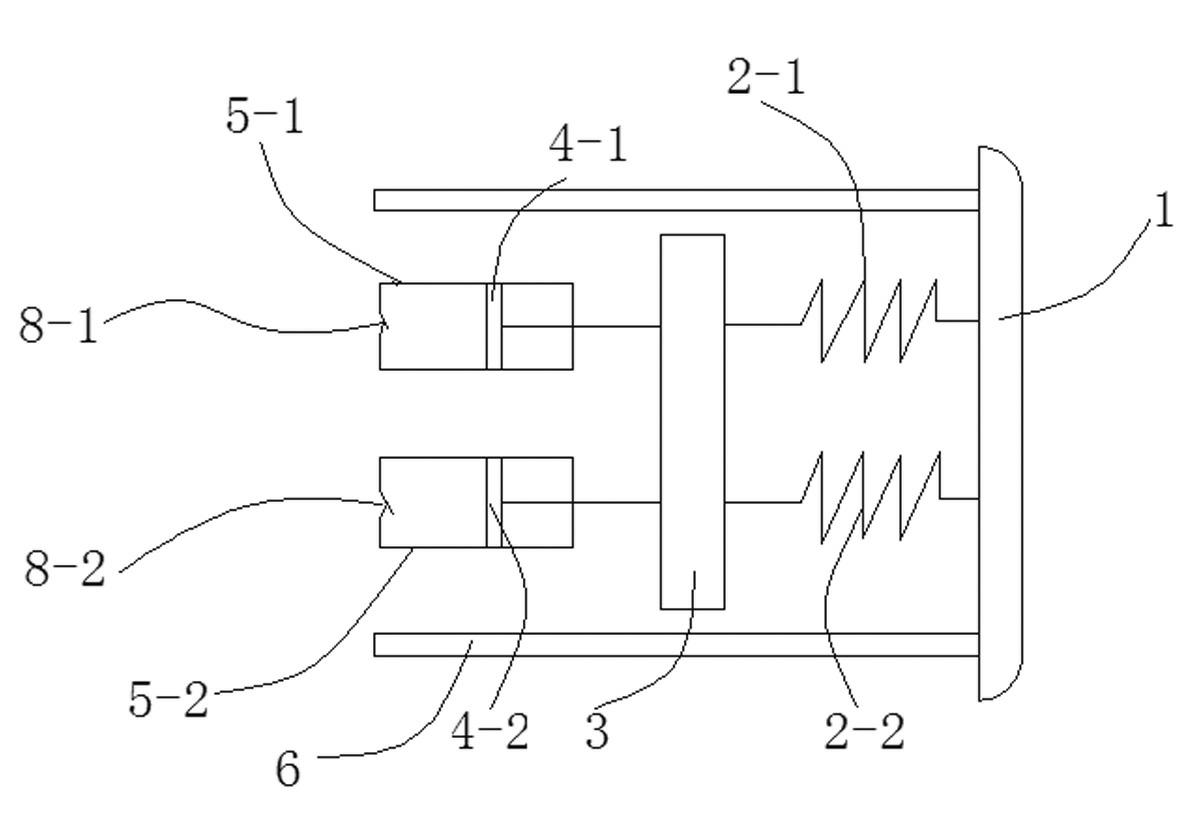

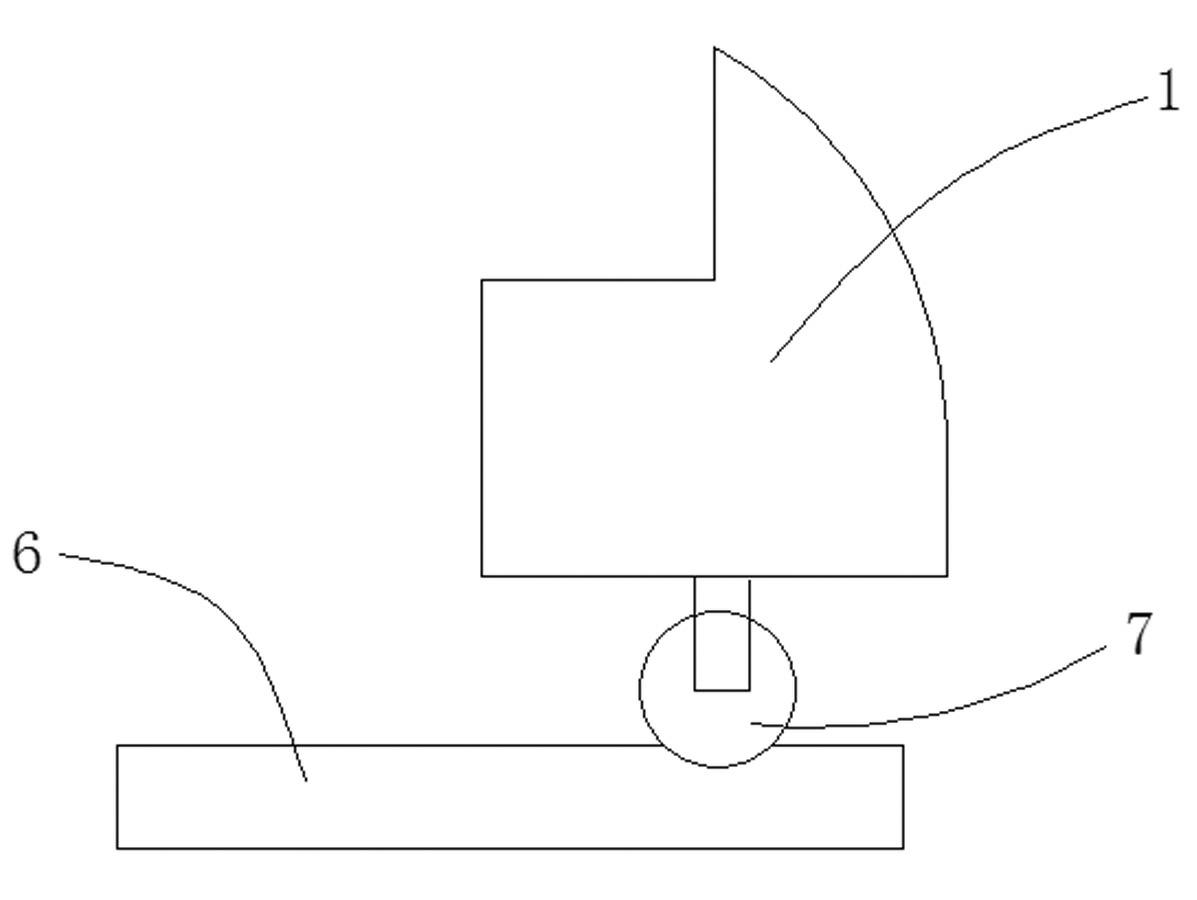

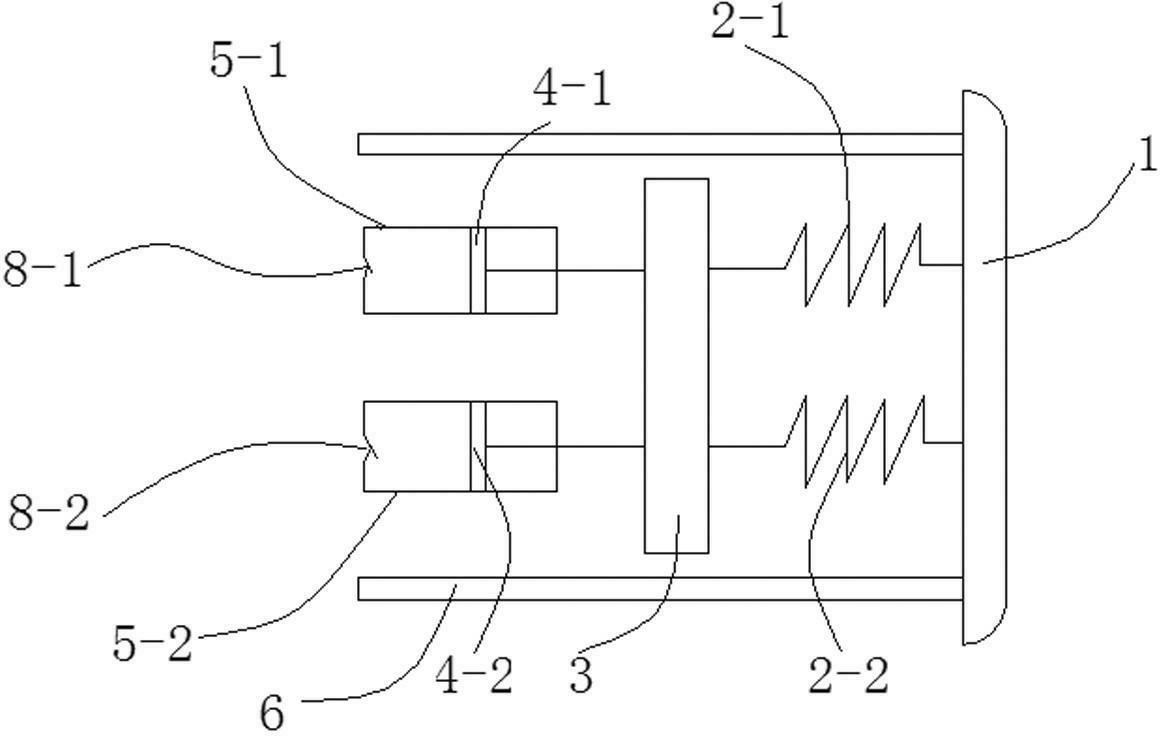

[0012] refer to figure 1 , this embodiment includes a bumper 1, a damping spring I2-1, a damping spring II2-2, a bracket 3, a piston I4-1, a piston II4-2, an air chamber I5-1 and an air chamber II5-2; the bumper 1 There are guide wheels on it ( figure 1 not shown), the air chamber I5-1 is provided with a one-way valve I8-1, and the air chamber II5-2 is provided with a one-way valve II8-2; the damping spring I2-1 and the damping spring One end of II2-2 is respectively connected with the bumper 1, and the other end is connected with the bracket 3; the piston I4-1 is located in the air chamber I5-1, and the piston II4-2 is located in the air chamber II5-2, and respectively pass through Piston rod links to each other with bracket 3.

[0013] When this embodiment is applied to a remote-controlled rail flat car, the bumper 1 is installed on the front or rear of the rail flat car, and other parts are installed on the bottom of the rail flat car; the bracket 3 is connected to the mo...

Embodiment 2

[0016] The difference between this embodiment and Embodiment 1 is that an air compression mechanism is provided at the end of the air chamber with a valve.

[0017] Usually, the air chamber is provided with a relatively high pressure gas (far less than the critical opening pressure of the valve). At this time, under the condition of attenuating the same impact energy, the required volume of the air chamber is greatly reduced, which is beneficial to the arrangement, or in the The attenuation efficiency and the total impact energy that can be attenuated can be improved under the same volume of the air chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com