Carbide slag powdering process and system

A technology of powder making system and calcium carbide slag, which is applied in the field of calcium carbide slag powder making technology and system, which can solve the problems of low desulfurization efficiency, insufficient oxygen content, easy absorption of water and moisture of calcium carbide slag and block the screen, etc., and achieves high screening accuracy and is not easy The effect of bonding and ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

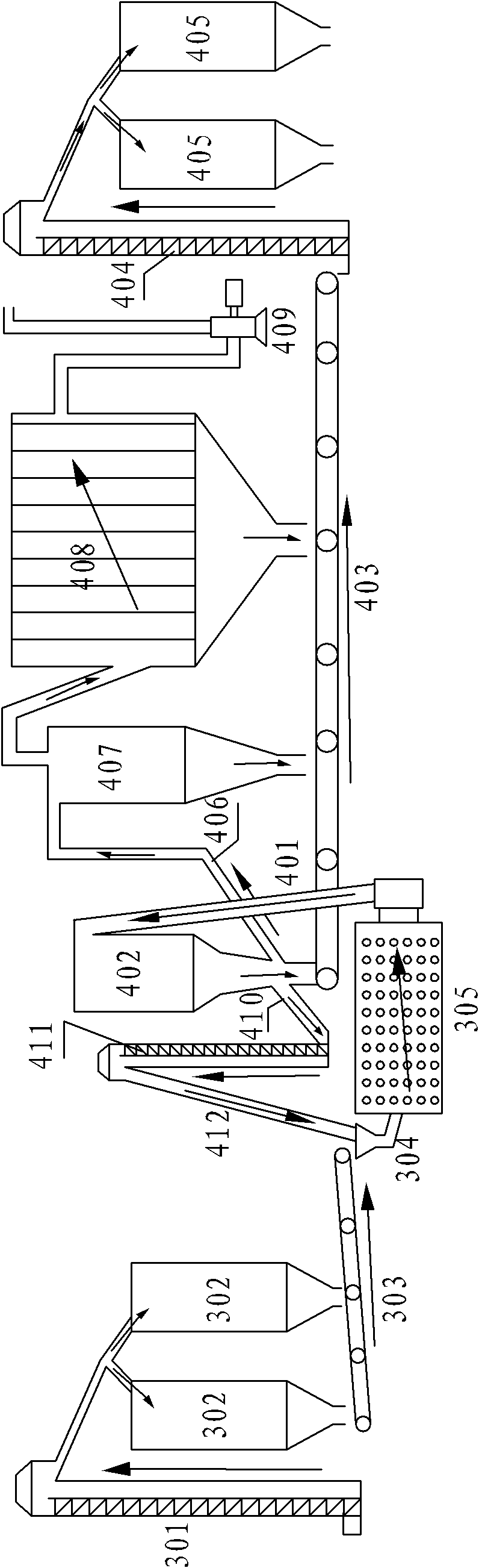

Image

Examples

Embodiment 1

[0036] A certain place is rich in calcium carbide slag resources, the price of carbide slag is 30-50 yuan / ton, and there is a stable source of raw materials. The price of limestone is between 150-300 yuan / ton according to the quality difference, and the price of lime is 400-600 yuan / ton. There are many coal-fired power plants within 300 kilometers, and 90% of them adopt desulfurization processes such as limestone-gypsum wet method, carbide slag-gypsum wet method, and slaked lime semi-dry method.

[0037] The calcium carbide slag powder preparation project has an investment of 5 million yuan, a total installed capacity of 300Kw, an annual output of 80,000 tons, an operating cost of 2 million yuan, and a finished carbide slag powder price of 150-200 yuan / ton, bringing economic benefits of more than 5 million yuan per year.

Embodiment 2

[0039] A calcium carbide slag mill adopts the process system provided by the patent of the present invention. The quality parameters of the calcium carbide slag feed are: moisture content -32%, Ca(OH) 2 -85% (dry basis), CaCO 3 -11% (dry basis), impurity (containing sulfur, phosphorus and other reducing substances) -4%, COD-9.3mg / g (dry basis), directly applied to this calcium carbide slag desulfurization system, hourly calcium carbide slag (wet base) consumption is 12t, the gypsum purity of the desulfurization system is 89.5%, the sulfite content is 6%, the COD of desulfurization wastewater raw water is 800mg / L, and it can reach 300mg / L by aeration treatment.

[0040] When processing the calcium carbide slag, the temperature of the rotary kiln is controlled at 850-900°C, and the powder separator with a particle size greater than 325 mesh is sent back to the ball mill for circular grinding. , Ca(OH) 2 -31.6%, CaCO 3 -1.5%, impurity (containing sulfur, phosphorus and other r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com