Comprehensive nutrition powder and preparation method thereof

A nutritional powder and comprehensive technology, applied in the field of nutrients, to achieve the effects of comprehensive nutrition, improved palatability, and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of comprehensive nutrition powder, is finished by following preparation method:

[0052] (1) Impurity removal: choose natural air-dried corn, and remove impurities twice;

[0053] (2) Moisturizing: Wetting the corn so that the surface moisture content is 25%;

[0054] (3) Peeling and degerming: three times of peeling and degerming to make it 99.9% pure;

[0055] (4) Crushing: crush the corn in step (3) to a particle size of 1 mm;

[0056] (5) Expansion: Grinding 50% of the corn granules in step (4) to 60 mesh and then puffing, and then grinding to 120 mesh again after puffing to obtain corn puffed powder;

[0057] (6) Grinding: Grinding the remaining 50% of the corn grains in step (4) to 120 mesh to obtain fine corn flour;

[0058] (7) Flour blending: 10 parts by weight of puffed corn flour, 20 parts of fine corn flour, 5 parts of fine soybean flour and 65 parts of wheat flour are evenly mixed to prepare comprehensive nutrition powder.

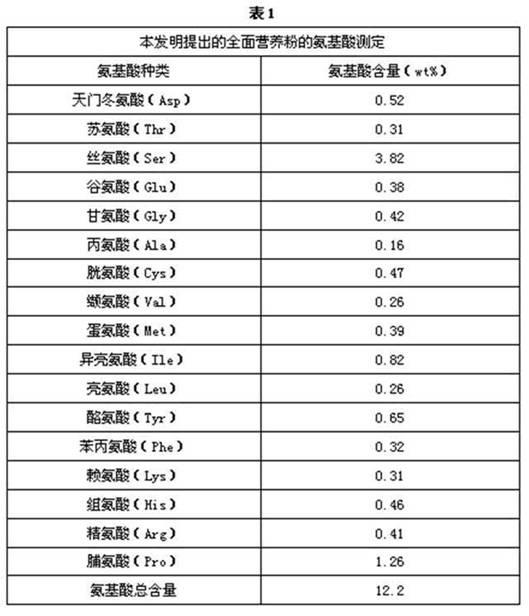

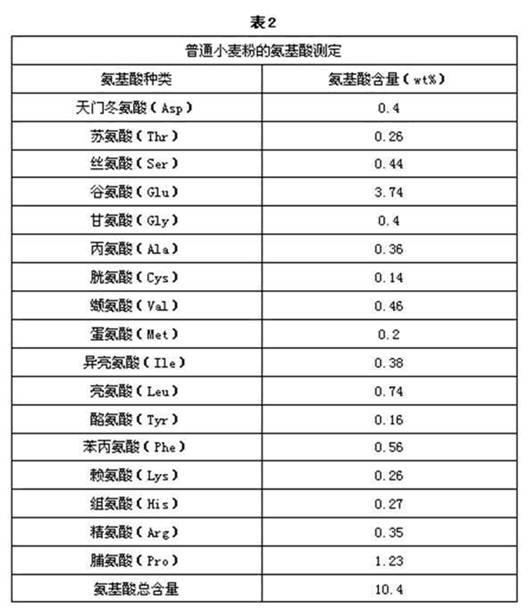

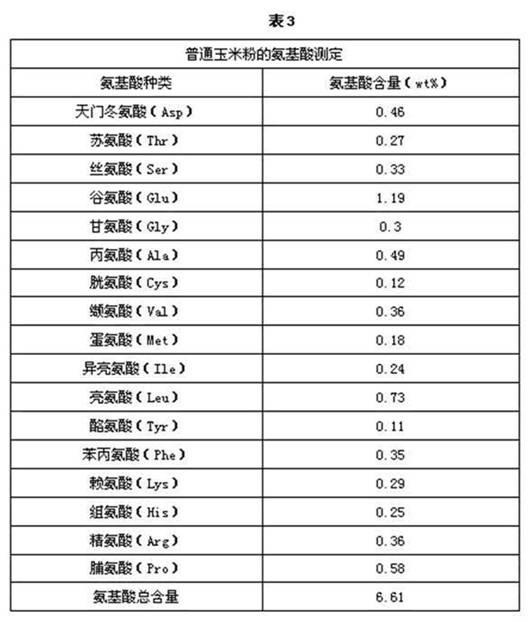

[0059] Wherein, the n...

Embodiment 2

[0071] A kind of comprehensive nutrition powder, is finished by following preparation method:

[0072] (1) Impurity removal: choose natural air-dried corn and perform 3 times of impurity removal;

[0073] (2) Moisturizing: Wetting the corn so that the surface moisture content is 25%;

[0074] (3) Peeling and degerming: four times of peeling and degerming, so that the purity is 95%;

[0075] (4) Crushing: crush the corn in step (3) to a particle size of 3 mm;

[0076] (5) Expansion: Grinding 50% of the corn granules in step (4) to 40 mesh and then puffing, and then grinding to 120 mesh again after puffing to obtain corn puffed powder;

[0077] (6) Grinding: Grinding the remaining 50% of the corn grains in step (4) to 120 mesh to obtain fine corn flour;

[0078] (7) Flour blending: 20 parts by weight of puffed corn flour, 10 parts of fine corn flour, 5 parts of fine soybean flour and 65 parts of wheat flour are evenly mixed to prepare comprehensive nutrition powder.

Embodiment 3

[0080] A kind of comprehensive nutrition powder, is finished by following preparation method:

[0081] (1) Impurity removal: choose natural air-dried corn and perform 3 times of impurity removal;

[0082] (2) Moisturizing: Wetting the corn so that the surface moisture content is 25%;

[0083] (3) Peeling and degerming: three times of peeling and degerming, so that the purity is 96%;

[0084] (4) Crushing: crush the corn in step (3) to a particle size of 2mm;

[0085] (5) Expansion: Grinding 50% of the corn granules in step (4) to 50 mesh and then puffing, and then grinding to 120 mesh again after puffing to obtain corn puffed powder;

[0086] (6) Grinding: Grinding the remaining 50% of the corn grains in step (4) to 120 mesh to obtain fine corn flour;

[0087] (7) Flour blending: 20 parts by weight of puffed corn flour, 20 parts of fine corn flour, 2 parts of fine soybean flour and 58 parts of wheat flour are evenly mixed to prepare a comprehensive nutritional powder.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com