Liquid edible fungus strain culture device and culture method

A technology of liquid strains and cultivating devices, which is applied in the fields of botanical equipment and methods, applications, and horticulture, can solve the problems of difficult detection of hidden bacteria, low success rate, and small amount of cultivation, and achieves low equipment price, The effect of avoiding pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

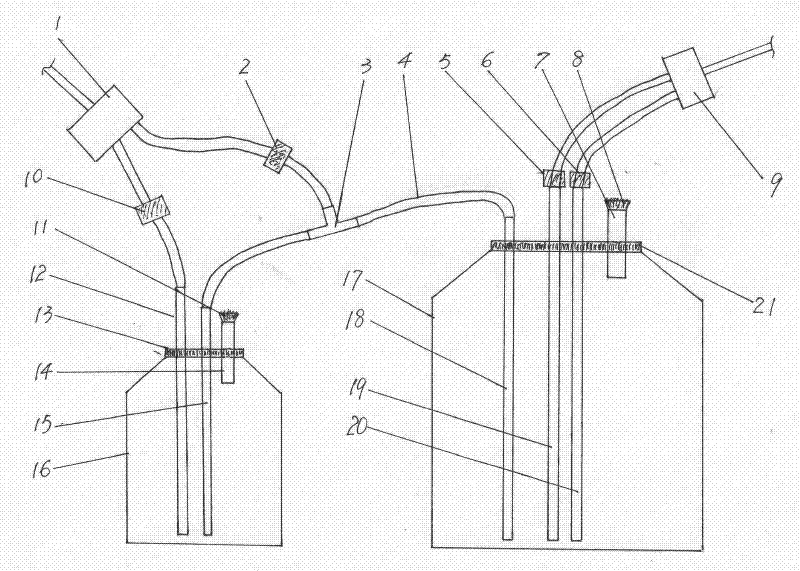

[0009] as attached figure 1 As shown, the culture device comprises a 5-liter glass primary fermentation bottle 16, a 75-liter plastic secondary fermentation tank 17, liquid medium inlet and outlet pipes 15, 18, air inlet pipes 12, 19, 20, air outlet pipe 7, etc. , first boil 60 liters of liquid culture medium with a stainless steel barrel, pour it into 56 liters in the secondary fermentation tank 17 while it is hot, and pour 4 liters in the primary fermentation bottle 16. The inoculation test tube 14 of 18 millimeters of diameters is inserted on the sealing rubber stopper 13 of primary fermentation bottle 16, and inoculation test tube 14 is bottomless, and the bottom is provided with a line net, and the nozzle stopper has cotton plug 11, is used for inoculation and exhaust, Insert the glass inlet pipe 12 and the liquid culture medium inlet and outlet pipe 15 for air intake of 8 millimeters of calibers again; Insert the liquid culture medium inlet and outlet pipe 18, the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com