Rear windshield glass electric-heating hot line and bus bar shape of automobile

A rear windshield and electric heating technology, applied in the direction of transparent/reflective heating devices, etc., can solve the problems of uneven glass surface temperature, glass fragmentation, high glass surface temperature, etc., and achieve low glass surface temperature, not easy to break, and save energy The effect of silver paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Please refer to the accompanying drawings for a further description of the present invention.

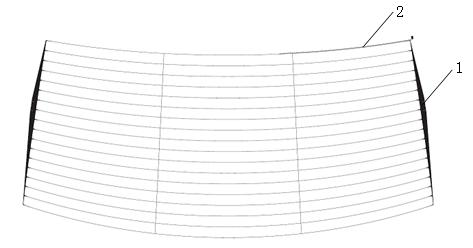

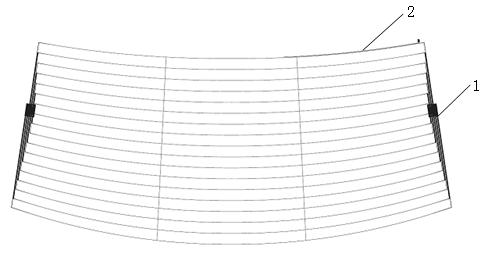

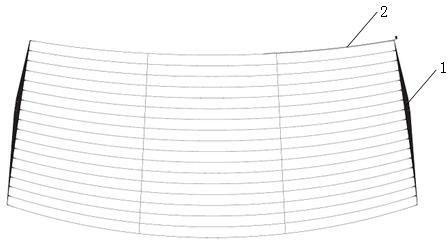

[0014] Such as figure 1 with figure 2 As shown, the present invention provides a shape of the busbar of the windshield heating wire after electric heating of the automobile, and the shape of the busbar 2 connected and converging with each heating wire 2 is spindle-shaped or radial.

[0015] Use graphic design software to change the shape of the busbar 1 into a spindle shape or a radial shape, and make this image as a photographic negative; follow the screen printing process, expose the photographic negative and the screen frame together, and then develop it, and the printing screen is what you need graphic shape.

[0016] Measure the temperature of the outer surface of the glass at the busbar, and compare the surface temperature with that of products whose busbar is rectangular, as shown in Table 1.

[0017]

[0018] Cooling effect: From Table 1, it can be calculated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com