Preparing device for keratin original fibers with forked head ends and method

A keratin, slimming technology, applied in the direction of liquid/gas/vapor treatment transmission, fiber treatment, animal fiber, etc., can solve the problems of weak head end grip, easy slippage and damage, etc., to increase the grip point And the effect of holding area, abundant raw materials, and increased surface area increase rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

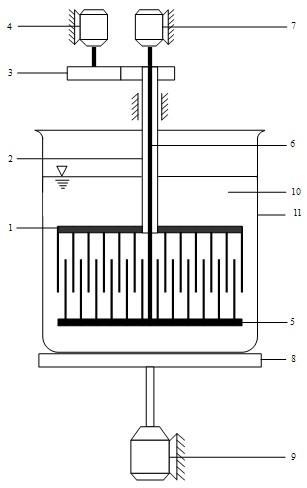

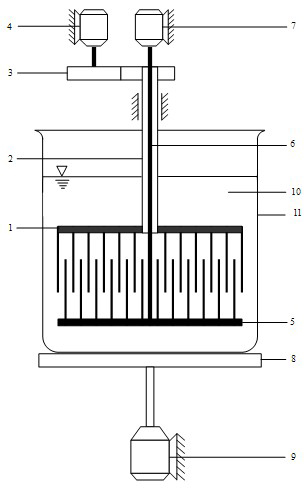

[0029] Such as figure 1 As shown, it is a structural schematic diagram of a differential mechanical stirring device. The differential mechanical stirring device includes at least one stirring rod arranged in the container 11, and the described stirring rod includes a first transmission rod 2 and a The second transmission rod 6 in the first transmission rod 2, one end of the first transmission rod 2 is connected with the stirring comb 1, and the other end is connected with the transmission gear 3, and the transmission gear 3 is connected with the stirring comb stepper motor 4, and the second transmission rod 6 One end is connected with the lower stirring comb 5, the other end is connected with the lower stirring comb stepping motor 7, and the upper stirring comb 1 and the comb pieces of the lower stirring comb 5 are opposite. The container 13 is arranged on the sample stage 8, and the sample stage 8 is connected to the stepping motor 9 through a rotating shaft. The size, s...

Embodiment 2

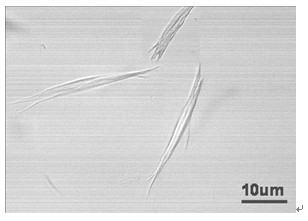

[0031] Cut the washed and dried wool into 5mm long fiber segments, immerse in 98% formic acid and boil for 10 minutes, then undergo ultrasonic vibration with a power of 400W for 10 minutes and then ultrasonic vibration with a power of 200W for 20 minutes to complete descaling. Immerse the descaled wool in 98% formic acid at a solid-to-liquid ratio of 1g / 100ml, and perform ultrasonic vibration at a frequency of 20kHz and a power of 200W in a constant temperature water bath at 20°C for 5h. Afterwards, undecomposed wool fibers were removed by filtration with a 100-mesh screen, and the filtrate was passed through a 400-mesh screen to obtain a spindle-shaped protofibril with a diameter of 4.8 μm and a length of 120.0 μm.

[0032] Using the differential mechanical stirring device described in Example 1, a formic acid solution 10 with a temperature of 20°C and a volume concentration of 85% was placed in a container 13, and a part of the spindle-shaped raw wool with a diameter of 4.8 μ...

Embodiment 3

[0034] The washed and dried cashmere was cut into 5 mm long fiber segments, which were consistent with the preparation method and steps of the wool protofibril in Example 1. Spindle-shaped fibrils with a diameter of 3.0 μm and a length of 105.5 μm were obtained.

[0035]Using the differential mechanical stirring device described in Example 1, place a formic acid solution 10 with a temperature of 40°C and a volume concentration of 70% in a container 13, and take a part of the cashmere spindle with a diameter of 3.0 μm and a length of 105.5 μm The fibrillar body is put into the formic acid solution 10, and the ultrasonic oscillation frequency is set to 20kHz, and the power is 150W; the rotation direction of the upper stirring comb 1 and the lower stirring comb 2 is opposite, the stirring frequency is 2Hz, and the rotation angle is 30°, using 6 There are two stirring rods, the number of comb pieces of the upper stirring comb 1 and the lower stirring comb 2 is 4, the rotational sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com