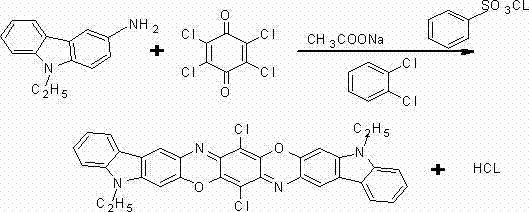

Environment-friendly production method for permanent violet RL

A production method, permanent violet technology, applied in the field of synthetic technology of permanent violet RL, can solve the problems of low conversion rate, harsh transportation and storage management conditions, high cost of use, etc., to achieve convenient temperature control, high product quality and The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

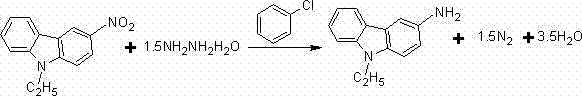

Method used

Image

Examples

Embodiment 1

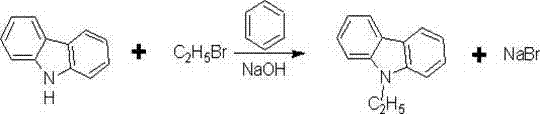

[0033] 1. Alkylation

[0034] 1. Put 500kg of recovered liquid caustic soda into the enamel alkylation reaction kettle, with an alkalinity of 31~33% (mass percentage concentration), and then use 96~99% solid sodium hydroxide (industrial grade) to adjust the alkalinity to reach 40~42%;

[0035] 2. Adjust the temperature to 28~32°C while stirring, and then put in 200kg of carbazole and 3.2kg of catalyst benzyltriethylammonium chloride;

[0036] 3. After adding carbazole and catalyst, cover the lid of the kettle, and add 110kg of pure benzene (from the high level tank of pure benzene) under stirring;

[0037] 4. Then add bromoethane 133.5kg (from bromoethane high level tank) in 20~30 minutes, and control the temperature here at 30~35℃;

[0038] 5. After adding, heat up to 88~90°C in 70~90 minutes, and keep the temperature at 88~90°C for 4.5~5 hours;

[0039] 6. After the heat preservation reaction is completed, heat up to 126~130°C, and recover pure benzene by distillation; af...

Embodiment 2

[0087] 1. Alkylation

[0088] 1. Put 500kg of recovered liquid caustic soda into the enamel alkylation reaction kettle, with an alkalinity of 31-33% (mass percentage concentration), and then use 96-99% solid sodium hydroxide (industrial grade) to adjust the alkalinity to 40 ~42%;

[0089] 2. Adjust the temperature to 28~32°C while stirring, and then put in 200kg of carbazole and 3.2kg of catalyst benzyltriethylammonium chloride;

[0090] 3. After adding carbazole and catalyst, cover the lid of the kettle, and add 110kg of pure benzene (from the high level tank of pure benzene) under stirring;

[0091] 4. Then add bromoethane 140kg (from bromoethane high level tank) in 20~30 minutes, and control the temperature here at 30~35℃;

[0092] 5. After adding, heat up to 85~87°C in 70~90 minutes, and keep the temperature at 85~87°C for 4.5~5 hours;

[0093] 6. After the heat preservation reaction is completed, heat up to 126~130°C, and recover pure benzene by distillation; after the...

Embodiment 3

[0142] 1. Alkylation

[0143] 1. Put 500kg of recovered liquid caustic soda into the enamel reaction kettle, with an alkalinity of 31~33% (mass percentage concentration), and then use solid potassium hydroxide (industrial grade) with a content of 96~99% to adjust the alkalinity to 46~48% ;

[0144] 2. Adjust the temperature to 28~32°C while stirring, and then put in 200kg of carbazole and 3.2kg of catalyst benzyltriethylammonium chloride;

[0145] 3. After adding carbazole and catalyst, cover the lid of the kettle, and add 110kg of pure benzene (from the high level tank of pure benzene) under stirring;

[0146] 4. Then add bromoethane 140kg (from bromoethane high level tank) in 20~30 minutes, and control the temperature here at 30~35℃;

[0147] 5. After adding, heat up to 85~87°C in 70~90 minutes, and keep the temperature at 85~87°C for 4.5~5 hours;

[0148] 6. After the heat preservation reaction is completed, heat up to 126~130°C, and recover pure benzene by distillation;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com