Anion slow-cracking asphalt emulsifying agent and preparation method thereof

The technology of asphalt emulsifier and anion is applied in the field of anionic slow-cracking asphalt emulsifier and its preparation, which can solve the problems of unguaranteed quality of emulsified asphalt and CA mortar, poor fluidity and high cost, and achieves easy product quality assurance, The effect of simplifying the preparation process and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An example of preparing the anionic slow-cracking asphalt emulsifier of the present invention is as follows: after taking 5 parts of fatty alcohol polyoxyethylene ether for heating and dissolving (temperature 55 ℃-60 ℃), add 1 part of water, the temperature is controlled at 55 ℃-60 ℃, slowly (Process 2 hours) After adding 2.5 parts of sodium lignosulfonate, add 1.5 parts of carboxylate anionic surfactant, and let it react for 2 hours at a constant temperature of 55°C-60°C to obtain a product with a pH value of 8-10.

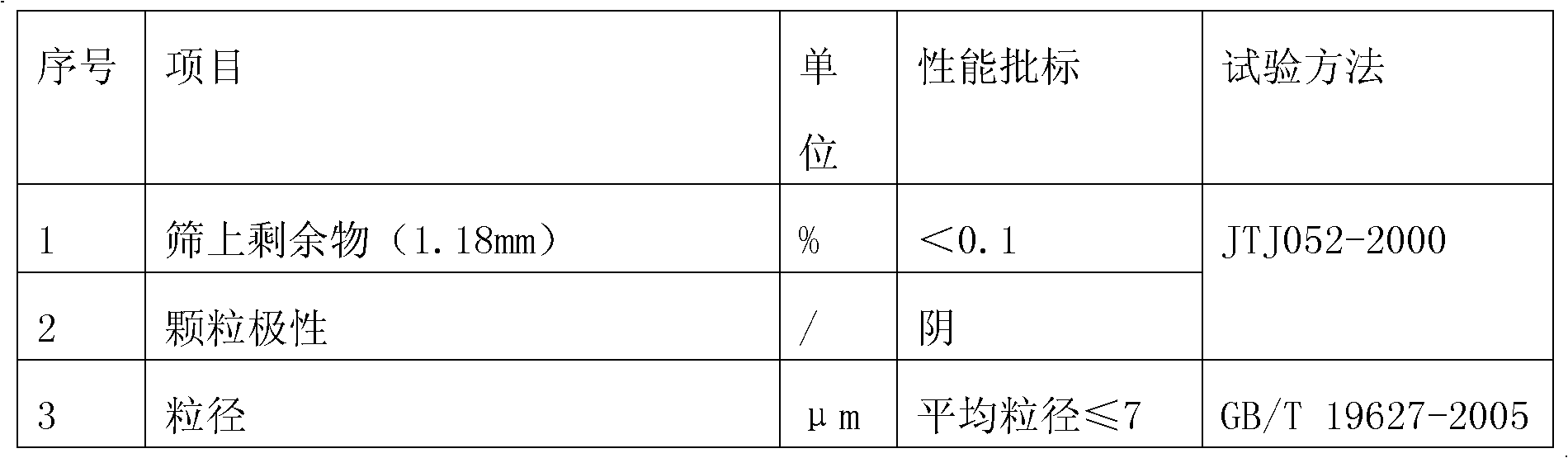

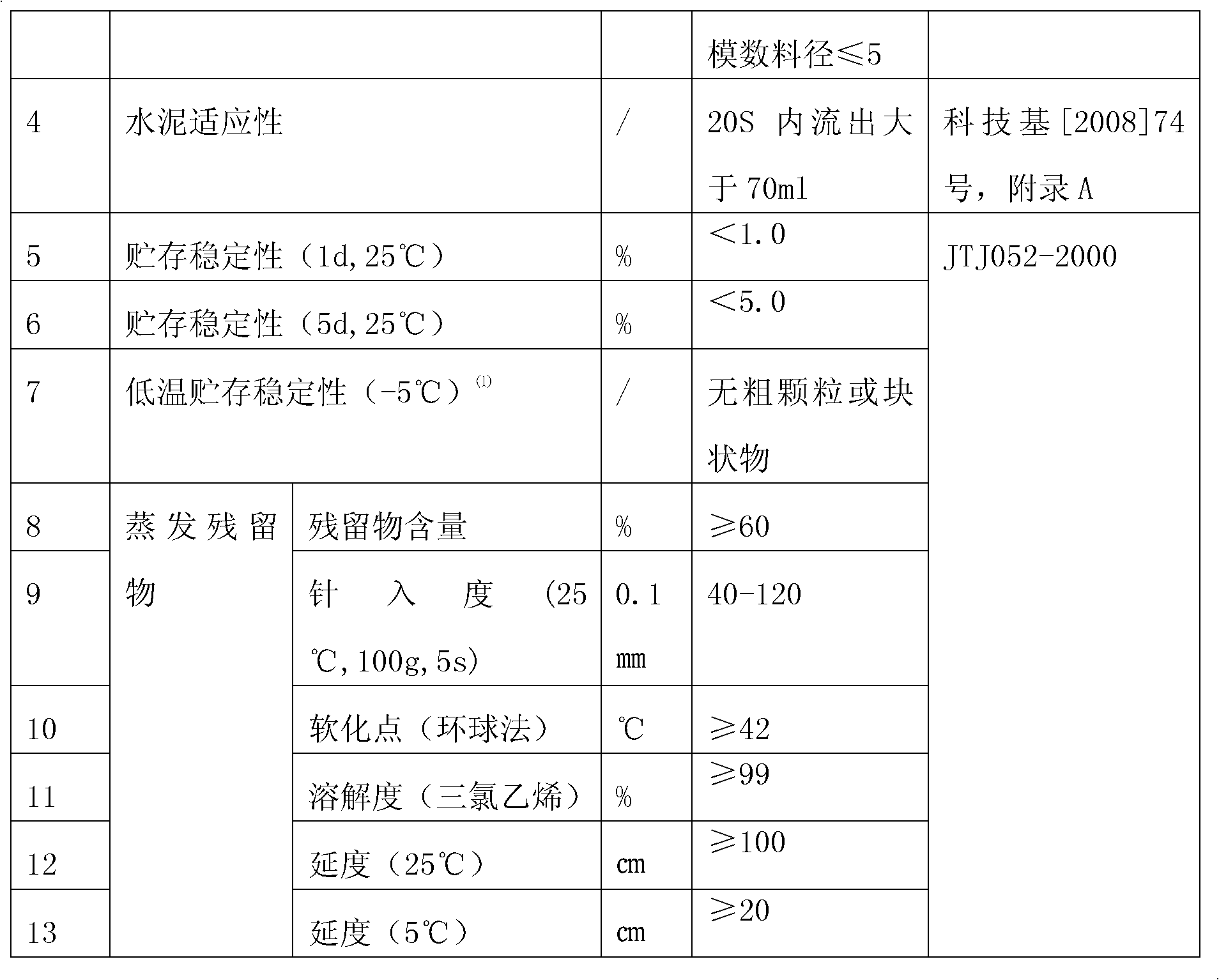

[0011] The use method when preparing emulsified asphalt with the above-mentioned embodiment is: asphalt ≥ 60%; 3-4% of anionic slow-cracking asphalt emulsifier of the present invention, 0.05-0.1% of JY-WD2 anionic stabilizer (dissolved in cold water 1:300 before use) ); water was added to 100%; adjusted to PH11-12 with alkali; oil temperature 135 ℃-145 ℃; emulsion temperature 55 ℃-60 ℃. The above ingredient percentages are by weight. The detection indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com