Powdery calcium-zinc complex heat stabilizer and preparation method and application thereof

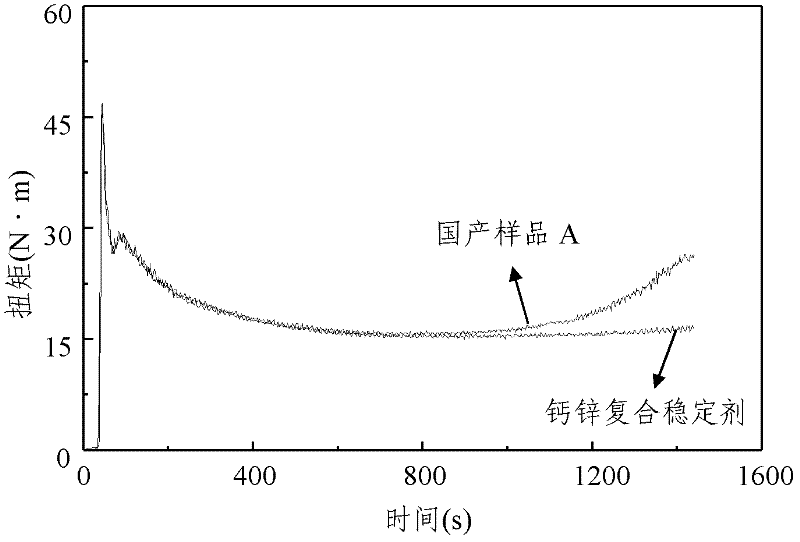

A technology of calcium-zinc composite heat stabilizer, which is applied in the field of powder calcium-zinc composite heat stabilizer and its preparation, can solve the problems of insufficient initial and long-term stability, vacancy, and inability to meet market demand, etc., and achieve the improvement of initial and long-term Thermal stability, improvement of dispersion performance and processability, effect of delaying zinc burning phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

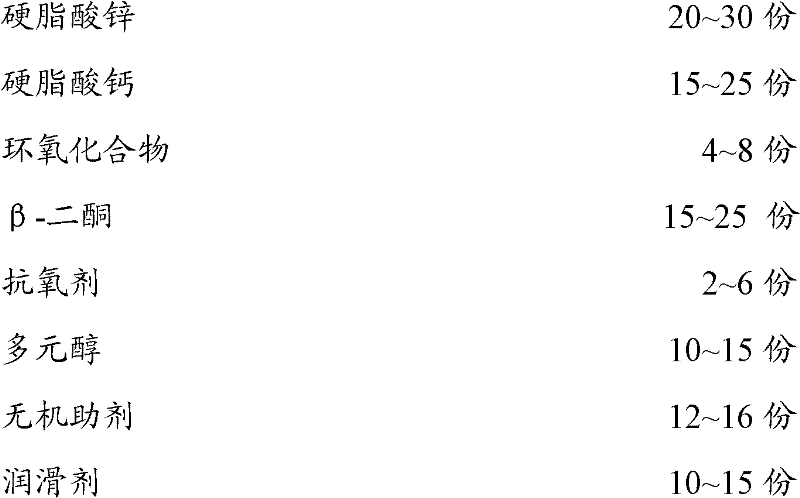

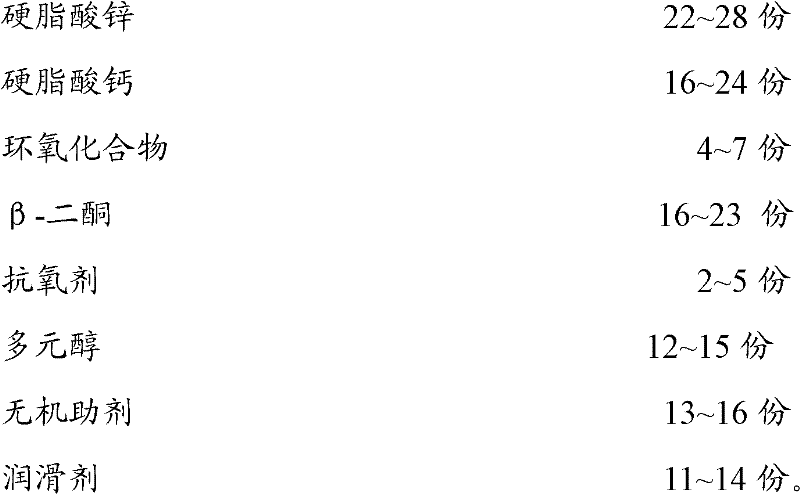

Embodiment 1

[0033] First take 8kg of epoxidized soybean oil into the reaction kettle, slowly raise the temperature to 50°C, then add 20kg of zinc stearate, 15kg of calcium stearate, 25kg of dibenzoylmethane, and 6kg of 2,6-di-tert-butyl-p-cresol , 15kg of pentaerythritol, 16kg of modified hydrotalcite (Dalian Haichen Chemical Mineral Co., Ltd.) and 15kg of polyethylene wax were mixed, melted, kept at 50°C and stirred for 2 hours, and the reaction mixture was cooled to room temperature to obtain a powder calcium-zinc composite thermal stabilizer 120kg.

Embodiment 2

[0035] First take 7kg of epoxy castor oil into the reactor, slowly heat up to 60°C, then add 22kg of zinc stearate, 16kg of calcium stearate, 23kg of stearoylbenzoylmethane, tetrakis [β-(3,5 -di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 5kg, sorbitol 15kg, modified hydrotalcite (Dalian Haichen Chemical Mining Co., Ltd.) 16kg mixes with oxidized polyethylene wax 14kg, melts, keeps The temperature was stirred at 60° C. for 3 hours, and the reaction mixture was cooled to room temperature to obtain 118 kg of powder calcium-zinc composite thermal stabilizer.

Embodiment 3

[0037] First take 6kg of epoxy linseed oil into the reaction kettle, slowly raise the temperature to 70°C, then add 24kg of zinc stearate, 20kg of calcium stearate, 22kg of dibenzoylmethane, tris[2.4-di-tert-butylphenyl] 4kg of phosphite, 14kg of maltitol, 15kg of modified zeolite (Ninghai County Jiahe Chemical Co., Ltd.) and 13kg of monoglyceride stearate were mixed, melted, kept at 70°C and stirred for 4 hours, and the reaction mixture was cooled to room temperature to obtain a powder Calcium-zinc composite heat stabilizer 118kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com