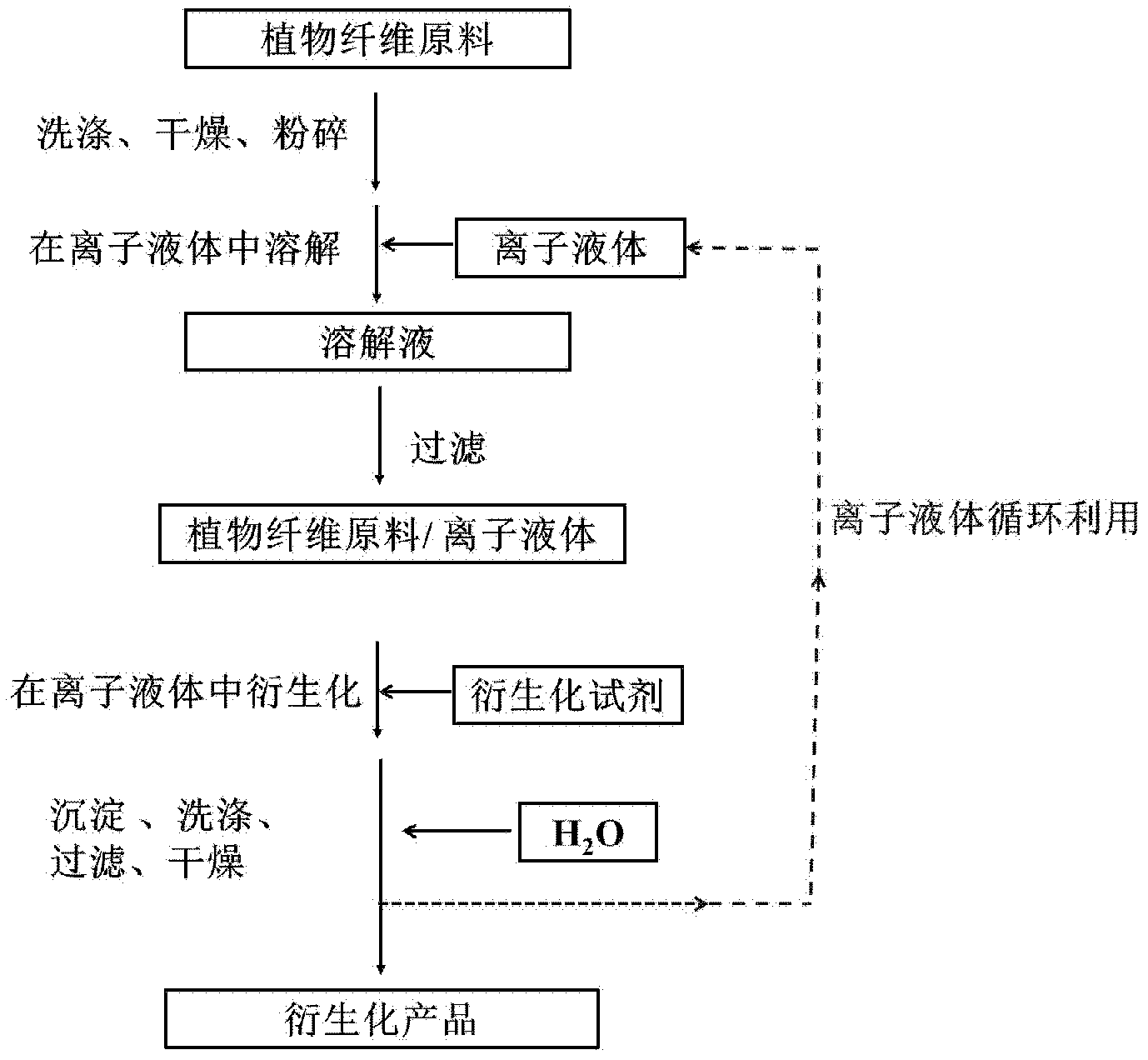

Method for homogeneously derivatizing plant fiber raw material by taking ionic liquid as medium

A plant fiber and ionic liquid technology, applied in the direction of organic chemistry, can solve problems such as difficult solvent recovery, environmental pollution, and process complexity, and achieve strong industrial application prospects, easy dissolution and recovery, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

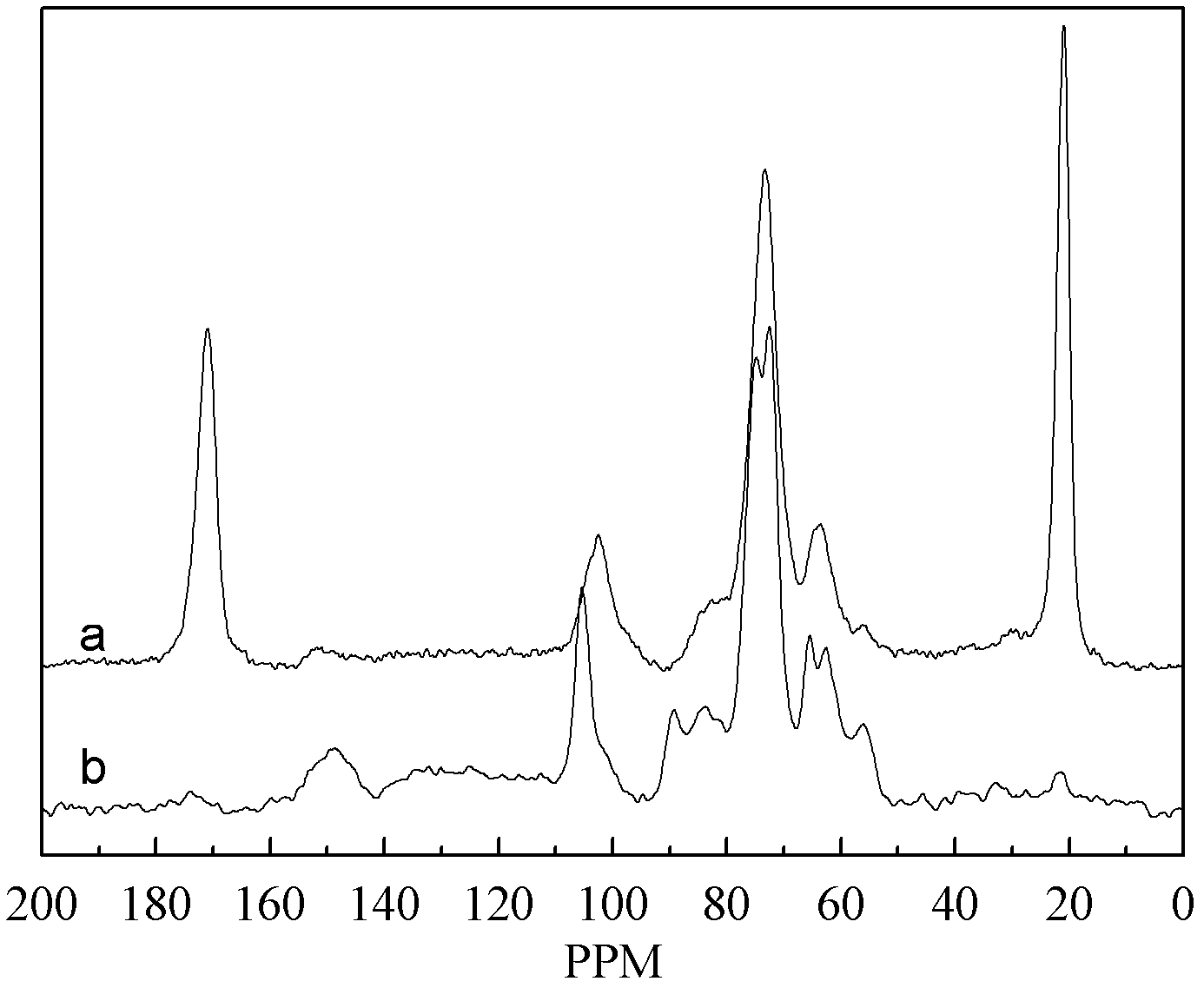

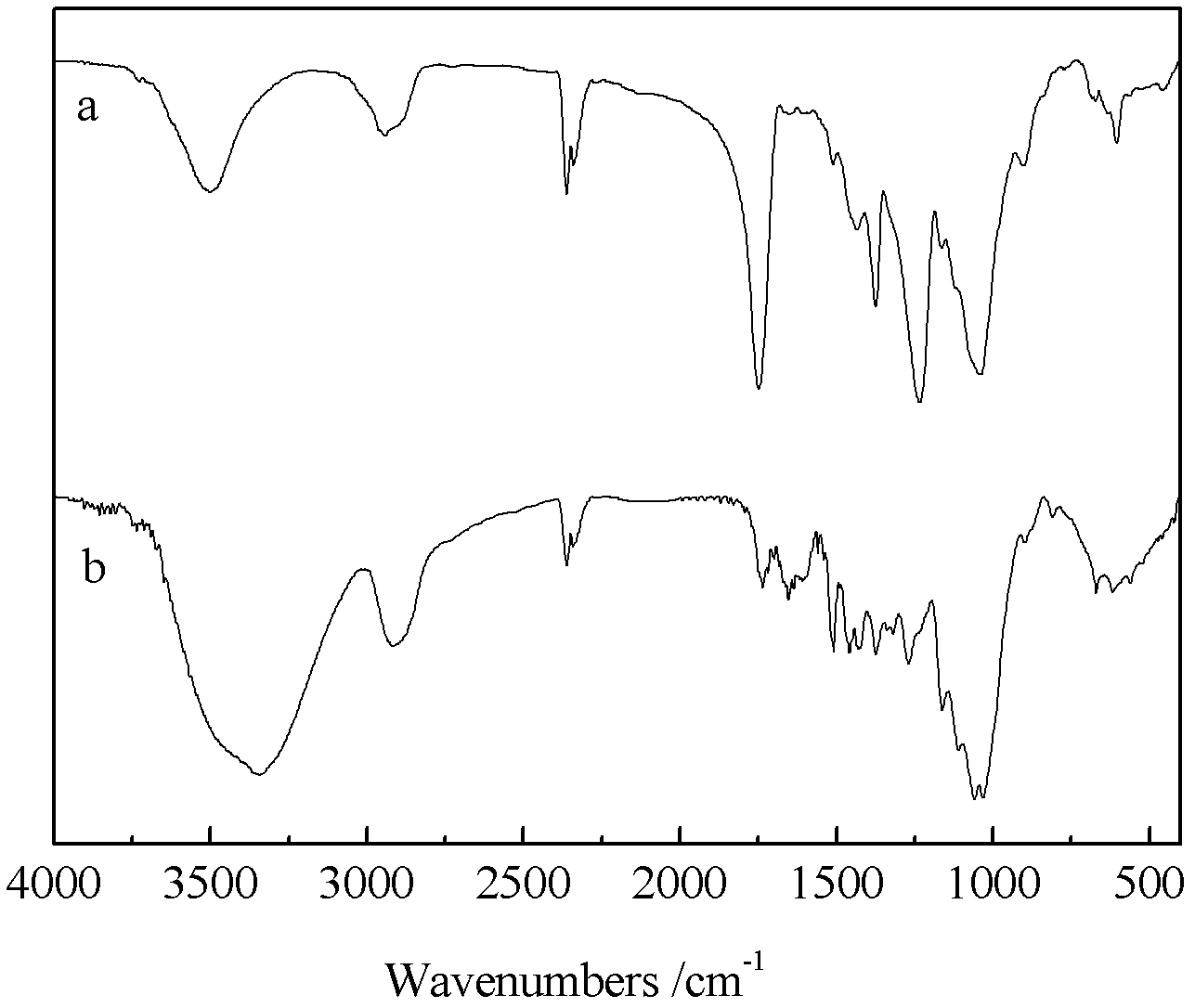

Embodiment 1

[0039] Weigh about 0.5 g of pine sawdust and 50.0 g of ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl), put them into a round-bottomed flask, heat to 110°C with microwave, and vigorously stir mechanically for 2 hours. After the dissolution, use a 300-mesh stainless steel filter to filter and separate.

[0040] Add 1.4 g of acetic anhydride to the filtrate, heat at 70° C. for 2 h, and add water to precipitate the product after the reaction is complete. Filtration, washing, and drying yielded a derivatized product with a WPG value of 156%.

Embodiment 2

[0042] Weigh about 0.5 g of pine sawdust and 50.0 g of ionic liquid 1-ethyl-3-methylimidazolium acetate (EmimAc), put them into a round-bottomed flask, heat to 100°C with microwave, and vigorously stir mechanically for 2 hours. After the dissolution, use a 400-mesh stainless steel filter to filter and separate.

[0043] Add 0.7 g of acetic anhydride to the filtrate, heat at 70° C. for 3 h, and add water to precipitate the product after the reaction is complete. Filter, wash, and dry to obtain a derivatized product with a WPG value of 95%.

Embodiment 3

[0045] Weigh about 0.5 g of pine sawdust and 50.0 g of ionic liquid 1-butyl-3-methylimidazolium chloride (BmimCl), put them into a round-bottomed flask, heat to 100°C with microwave, and vigorously stir mechanically for 3 h. After the dissolution, use a 280-mesh stainless steel filter to filter and separate.

[0046] Add 2.3 g of acetic anhydride to the filtrate, heat at 80° C. for 24 h, and add water to precipitate the product after the reaction is complete. Filtration, washing and drying yielded a derivatized product with a WPG value of 149%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com