Preparation method and application of coupled modified nanometer yttrium oxide

A technology of nano-yttrium oxide and yttrium oxide, which is applied in the petroleum industry, lubricating compositions, etc., to achieve good extreme pressure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

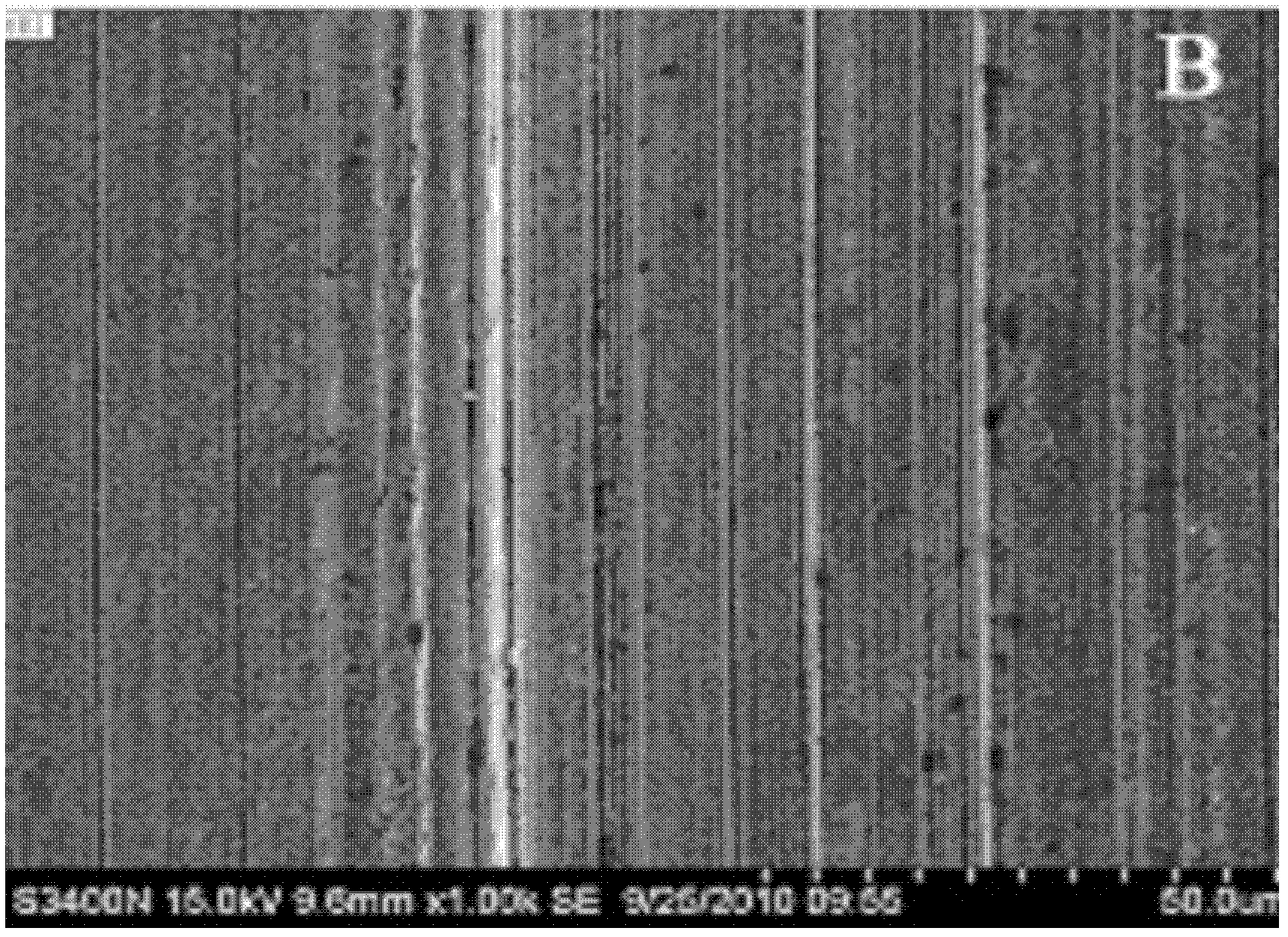

Image

Examples

Embodiment 1

[0019] Weigh nanometer yttrium oxide and ultrasonically disperse it in toluene solvent. Continue to add 0mL / g (Y 2 o 3 ) (this unit represents the volumetric amount of glacial acetic acid that needs to be added per gram of yttrium oxide, hereinafter the same) the amount of glacial acetic acid and silane coupling agent vinyltrimethylsilane, the ratio of yttrium oxide and silane coupling agent quality is 10: 2. Stir and react at 60°C for 2 hours, then centrifuge, use a Soxhlet extractor to extract homopolymers and unreacted monomers, and obtain silane coupling agent-modified yttrium oxide after vacuum drying. Then take the yttrium oxide modified by the silane coupling agent, and ultrasonically disperse it in toluene. The initiator azobisisobutyronitrile and the monomer methyl acrylate were respectively dissolved in toluene, the mass ratio of yttrium oxide to the monomer was 1:4, and the amount of the initiator was 0.4% relative to the mass of the monomer. Heated to 75°C under...

Embodiment 2

[0021] Weigh nanometer yttrium oxide and ultrasonically disperse it in toluene solvent. Continue to add 0.5mL / g (Y 2 o 3 ) amount of glacial acetic acid and silane coupling agent vinyltrimethylsilane, the mass ratio of yttrium oxide to silane coupling agent is 10:2, stirred and reacted at 90°C for 6h, then centrifuged, and extracted with a Soxhlet extractor The polymer and unreacted monomers are vacuum-dried to obtain yttrium oxide modified by a silane coupling agent. Then take the yttrium oxide modified by the silane coupling agent, and ultrasonically disperse it in toluene. The initiator azobisisobutyronitrile and the monomer methyl acrylate were respectively dissolved in toluene, the mass ratio of yttrium oxide to the monomer was 1:20, and the amount of the initiator was 2% relative to the mass of the monomer. Heated to 75°C under a nitrogen atmosphere, slowly added the initiator and reacted with the monomer for 5 hours, then centrifuged, extracted the homopolymer and un...

Embodiment 3

[0023] Weigh nanometer yttrium oxide and ultrasonically disperse it in toluene solvent. Continue to add 0.2mL / g (Y 2 o 3 ) amount of glacial acetic acid and silane coupling agent vinyltrimethylsilane, the mass ratio of yttrium oxide to silane coupling agent is 10:4, stirred and reacted at 70°C for 4h, then centrifuged, and extracted with a Soxhlet extractor The polymer and unreacted monomers are vacuum-dried to obtain yttrium oxide modified by a silane coupling agent. Then take the yttrium oxide modified by the silane coupling agent, and ultrasonically disperse it in toluene. The initiator azobisisobutyronitrile and the monomer methyl acrylate were respectively dissolved in toluene, the mass ratio of yttrium oxide to the monomer was 1:12, and the amount of the initiator was 1.3% relative to the mass of the monomer. Heated to 75°C under a nitrogen atmosphere, slowly added the initiator and reacted with the monomer for 3 hours, then centrifuged, extracted the homopolymer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com