Nano zero-valent iron modified composite mesoporous material and preparation method and application thereof

A technology of nano-zero-valent iron and mesoporous materials, applied in the field of composite materials, can solve the problems of easy agglomeration and passivation of nano-zero-valent iron, and achieve the advantages of low preparation cost, simple preparation process, and improved dispersibility and reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

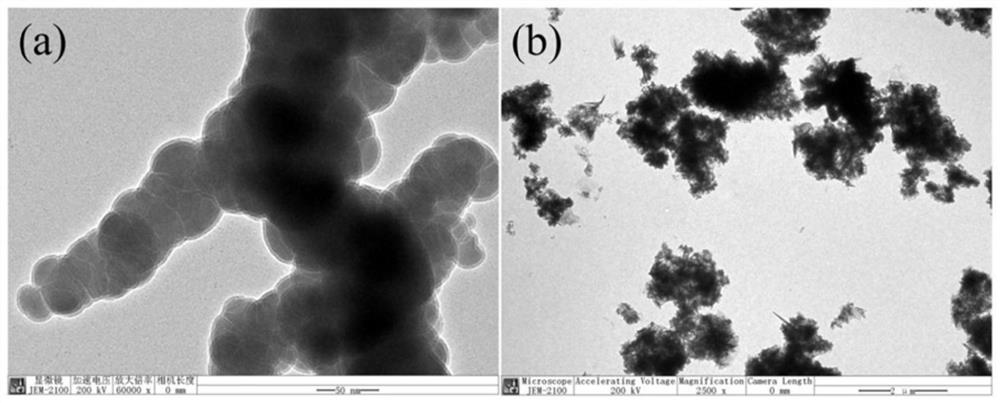

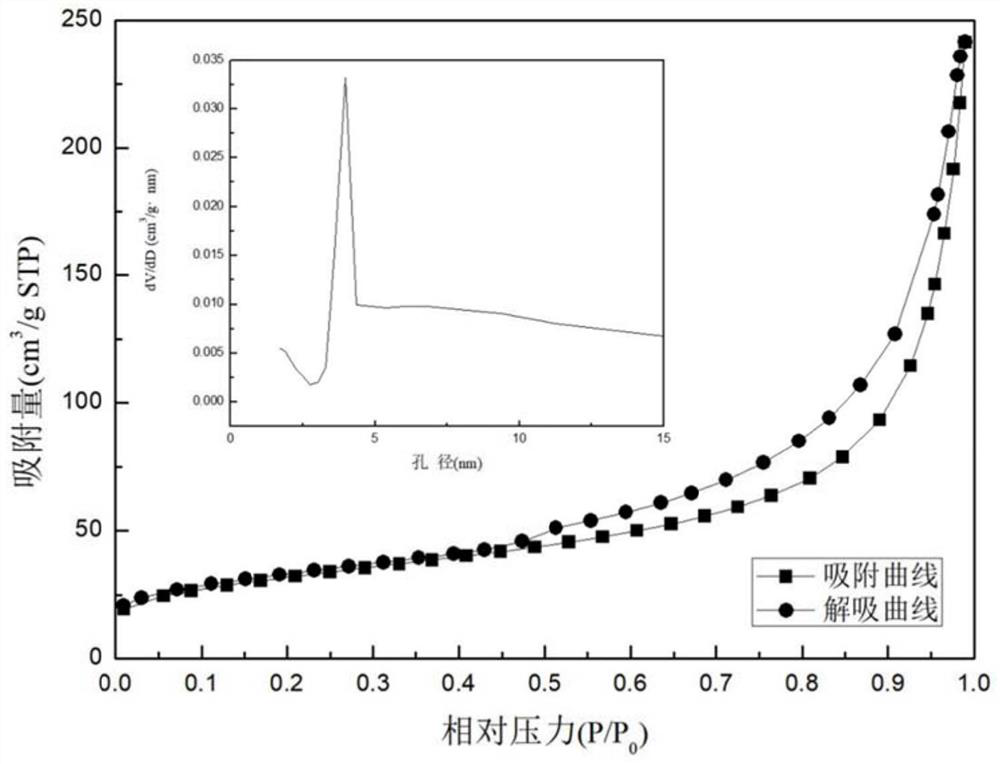

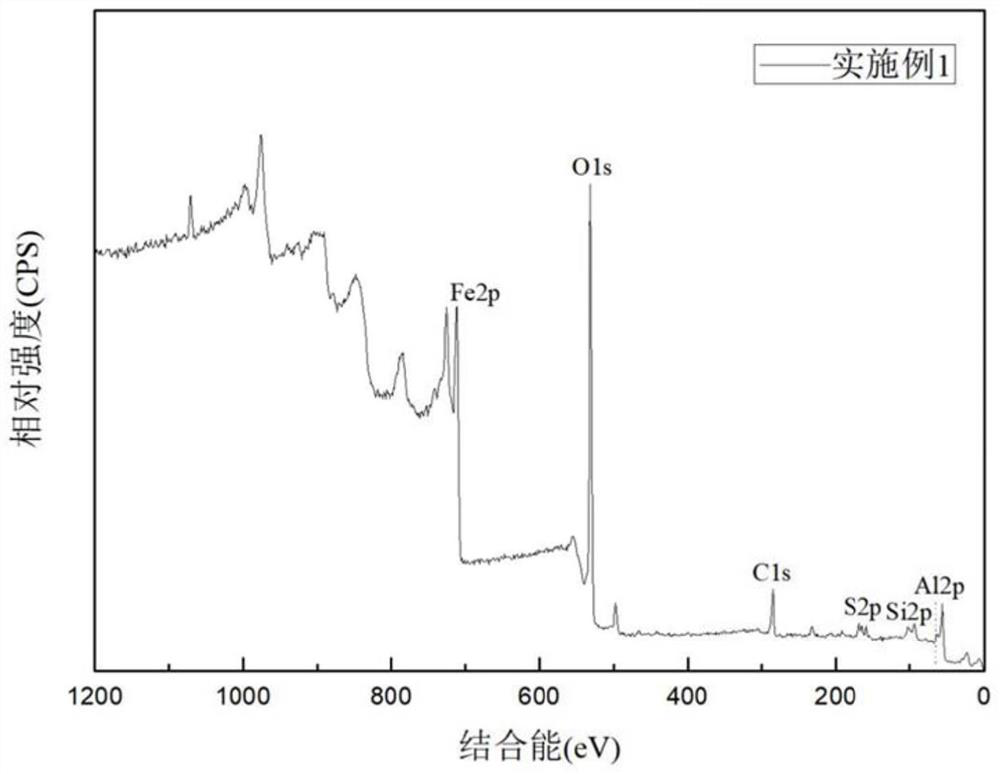

[0038] This embodiment provides a method for preparing a nano-zero-valent iron-modified composite mesoporous material, which specifically includes the following steps:

[0039] (1) Weigh 0.5g of ZSM-5 molecular sieve and dip it in 20mL of 0.059mol / L dilute hydrochloric acid solution for acid treatment, after magnetic stirring for 30min, wash with centrifugal water several times at 3000rpm;

[0040] (2) Mix and stir the acid-treated ZSM-5 molecular sieve and 10mL 2.983g (concentration 1.07%) graphene oxide solution in step (1) and then ultrasonically disperse. Dry at 110°C for 12 hours to obtain a dried product, which is washed several times by centrifugation at 3000 rpm, dried, and then ground into a powder for use;

[0041] (3) Take by weighing 0.498g ferrous sulfate heptahydrate and step (2) gained powdery product into three-necked flask together, add 70mL deionized water and 30mL dehydrated alcohol, after ultrasonic dispersion 15min, in N 2 Continuous mechanical stirring u...

Embodiment 2

[0049] This embodiment provides a method for preparing a nano-zero-valent iron-modified composite mesoporous material, which specifically includes the following steps:

[0050] (1) Weigh 0.5g of ZSM-5 molecular sieve and dip it in 20mL of 0.059mol / L dilute hydrochloric acid solution for acid treatment, after magnetic stirring for 30min, wash with centrifugal water several times at 3000rpm;

[0051] (2) Mix and stir the acid-treated ZSM-5 molecular sieve and 10mL 2.983g (concentration 1.07%) graphene oxide solution in step (1) and then ultrasonically disperse. Dry at 110°C for 12 hours to obtain a dried product, which is washed several times by centrifugation at 3000 rpm, dried, and then ground into a powder for use;

[0052] (3) Take by weighing 0.498g ferrous sulfate heptahydrate and step (2) gained powdery product into three-necked flask together, add 70mL deionized water and 30mL dehydrated alcohol, after ultrasonic dispersion 15min, in N 2 Continuous mechanical stirring u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com