Fibrous gypsum ecological wood material and preparation method thereof

A fiber gypsum, ecological technology, applied in the field of preparation of fiber gypsum ecological wood and production methods, can solve the problems of known patents and technical microstructure, hydration mechanism and molding methods, etc., to avoid high temperature thermal mismatch and save natural resources , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

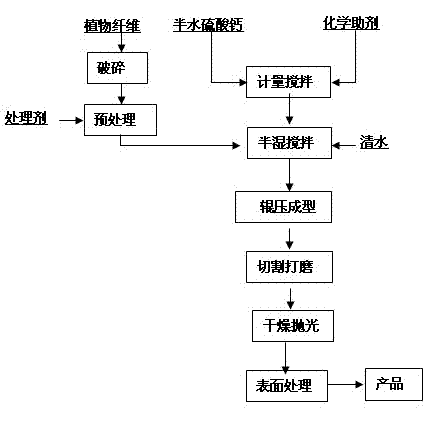

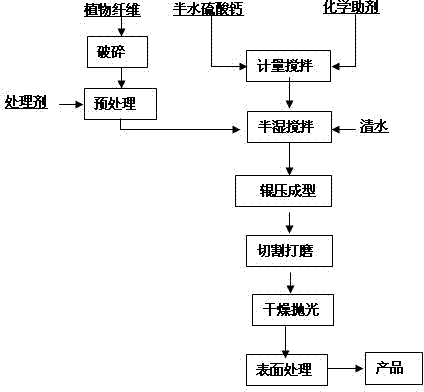

Method used

Image

Examples

Embodiment 1

[0026] 1. Composition of weight formula

[0027] 1) Calcium sulfate hemihydrate: 80 parts of β-type desulfurized hemihydrate gypsum, 20 parts of α-desulfurized hemihydrate gypsum;

[0028] 2) Plant fiber: 20 parts of bagasse;

[0029] 3) Chemical additives: 1.0 parts of water-soluble dispersible powder, 1.0 parts of waterproof silicon powder, 0.05 parts of sodium sulfoaluminate, and 0.03 parts of potassium citrate;

[0030] 4) Clear water: 18.75 parts.

[0031] 2. Production and preparation process:

[0032] (1) Raw material pretreatment: Bagasse is crushed into debris or short filaments with a length of 5-12 mm, a width of 0.5-5 mm, and a thickness of 0.1-5 mm, directly soaked and cooked in aqueous solution of sodium silicate and lime for 2 hours, and then centrifuged Dehydrate to a moisture content of 20-25%.

[0033] (2) Metering and stirring: 80 parts of β-type desulfurized hemihydrate gypsum, 20 parts of α-desulfurized hemihydrate gypsum, 20 parts of bagasse, and 2.0...

Embodiment 2

[0039] 1. Composition of weight formula

[0040] 1) Calcium sulfate hemihydrate: 100 parts of β-type desulfurized hemihydrate gypsum;

[0041] 2) Plant fiber: 20 parts of bagasse;

[0042] 3) Chemical additives: 1.0 parts of water-soluble dispersible powder, 1.0 parts of waterproof silicon powder, 0.08 parts of sodium sulfoaluminate, and 0.05 parts of potassium citrate;

[0043] 4) Clear water: 20 parts.

[0044] 2. Production and preparation process:

[0045] (1) Raw material pretreatment: Bagasse is crushed into debris or short filaments with a length of 5-12 mm, a width of 0.5-5 mm, and a thickness of 0.1-5 mm, directly soaked and cooked in aqueous solution of sodium silicate and lime for 2 hours, and then centrifuged Dehydrate to a moisture content of 20-25%.

[0046] (2) Metering and stirring: 100 parts of β-type desulfurized hemihydrate gypsum, 20 parts of bagasse, and 2.13 parts of chemical additives are respectively accurately measured and mixed in the mixer to form...

Embodiment 3

[0052] 1. Composition of weight formula

[0053] 1) Calcium sulfate hemihydrate: 100 parts of α-type desulfurized hemihydrate gypsum;

[0054] 2) Plant fiber: 12 parts of bagasse, 8 parts of sawdust;

[0055] 3) Chemical additives: 0.8 parts of water-soluble dispersible powder, 0.8 parts of waterproof silicon powder, 0.05 parts of sodium sulfoaluminate, and 0.03 parts of potassium citrate;

[0056] 4) Clear water: 19.17 parts.

[0057] 2. Production and preparation process:

[0058] (1) Raw material pretreatment: Bagasse is crushed into chips or short filaments with a length of 5-12mm, a width of 0.5-5mm, and a thickness of 0.1-5mm. The sawdust is used directly. After the two are measured according to the ratio, the silicon The aqueous solution of sodium bicarbonate and lime is soaked and boiled for 2 hours, then centrifuged and dehydrated to a moisture content of 20-25%.

[0059] (2) Metering and stirring: 100 parts of α-type desulfurized hemihydrate gypsum, 12 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com