Preparation method of superalloy

A technology of superalloy and deformed superalloy, which is applied in the field of superalloy preparation, can solve the problems of small hot working process window, difficult deformation, poor formability, etc., and achieves the effect of short ball milling time, few process steps, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of superalloy in the present embodiment is:

[0044] Preparation of high-purity master alloys by double or triple smelting of vacuum induction melting and / or electroslag remelting and / or vacuum induction consumable melting;

[0045] Then use argon atomization to prepare spherical superalloy particles;

[0046] Put the superalloy particles, oxide powder, grinding balls and ball milling tank into the hand box to evacuate, turn off the vacuum pump, fill with argon, when the pressure inside and outside the hand box is consistent, put the superalloy particles, oxide powder and grinding Put the ball into the jar, tighten the ball mill jar, then take out the ball mill jar from the hand box, and install it on the ball mill;

[0047] Start the ball mill for mixing ball milling, the ball-to-material ratio is 2:1-10:1, the ball milling speed is 300-600rad / min, and the ball milling time is 10-30h. The setting of the ball milling speed and time depends on the...

Embodiment 1

[0052]In the preparation method of the superalloy in this embodiment, the composition of the deformed superalloy particles is: Co 20%, Cr 15%, Ti 5.5%, Al 2%, W 2%, Mo 2%, Nb 1%, Ni Bal. These raw materials are smelted in a vacuum induction melting furnace according to the ratio, then refined in an electroslag furnace, and finally further refined in a vacuum induction consumable furnace. Before each step of refining, the ingot is peeled and the head and tail are cut. The prepared ingot is atomized by argon gas to prepare spherical superalloy particles.

[0053] Including the following steps,

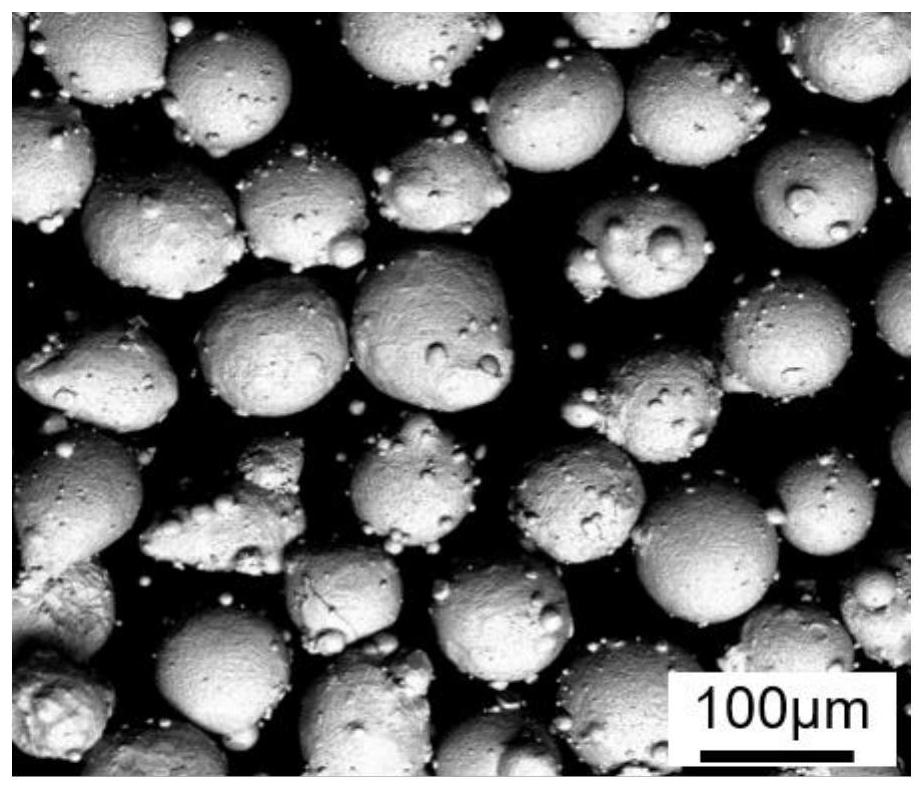

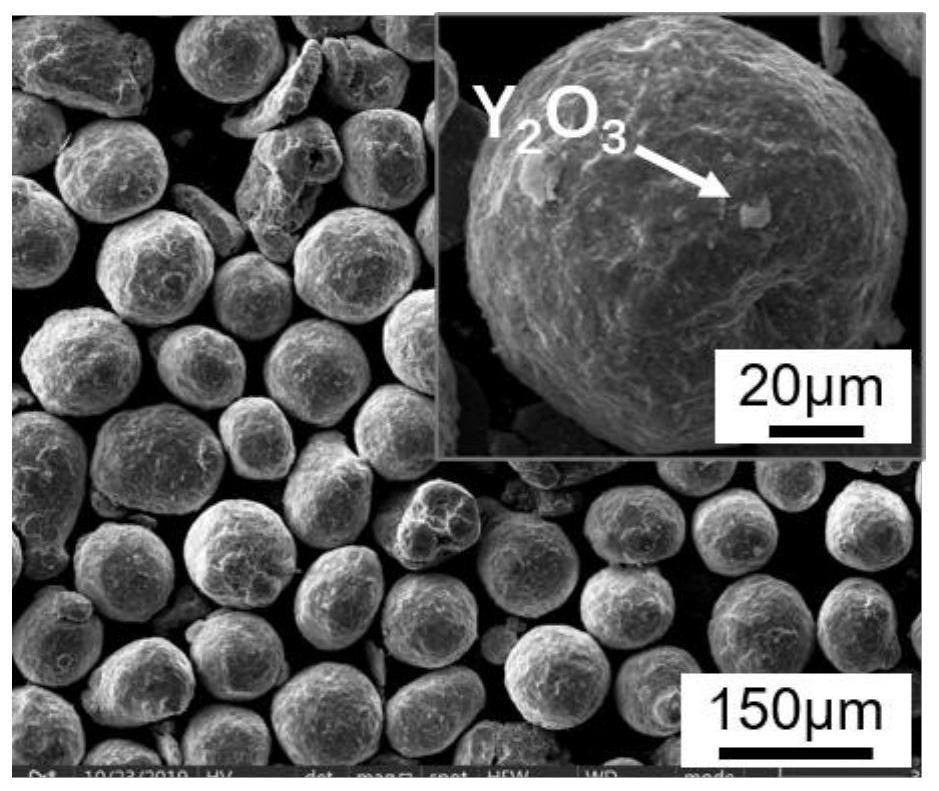

[0054] Step 1, ball milling: use a ball mill to grind superalloy particles with an average diameter of 100 μm (such as figure 1 ) and Y with an average size of 100nm 2 o 3 The powder is evenly mixed, Y 2 o 3 The mass fraction of the powder is 0.5%, the ball-to-material ratio is 2:1, the ball milling speed is 300rad / min, the ball milling time is 30h, and the Y 2 o 3 Embedded on the...

Embodiment 2

[0060] In the preparation method of the superalloy in this embodiment, the composition of the deformed superalloy particles is: Co 20%, Cr 15%, Ti 5.5%, Al 2%, W 2%, Mo 2%, Nb 1%, Ni Bal. These raw materials are smelted in a vacuum induction melting furnace according to the ratio, then refined in an electroslag furnace, and finally further refined in a vacuum induction consumable furnace. Before each step of refining, the ingot is peeled and the head and tail are cut. The prepared ingot is atomized by argon gas to prepare spherical superalloy particles.

[0061] Including the following steps,

[0062] Step 1, ball milling: use a ball mill to mix superalloy particles with an average diameter of 900 μm and ThO with an average size of 500 nm 2 Powder homogeneously mixed, ThO 2 The mass fraction of the powder is 1%, the ball-to-material ratio is 5:1, the ball milling speed is 400rad / min, the ball milling time is 20h, and ThO 2 Inlaid on the surface of large-sized deformed super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com