Preparation method of transition metal phosphide MoP

A technology of transition metals and phosphides, which is applied in the direction of phosphides, can solve the problems of difficult control of product crystal phase, poor catalytic activity of products, and inability to prepare phosphides, etc., and achieves the effect of low price, low cost and novel synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Precursor preparation

[0021] Weigh at a molar ratio of 1:14 (NH 4 ) 6 Mo 7 o 24 4H 2 O and NH 4 h 2 PO 4 , solid-phase reaction occurs by grinding in a mortar; continue to grind until dry, and sinter the resulting powder at 500 °C for 5 h to obtain a precursor.

Embodiment 1

[0023] 1. Weigh the above precursor and KBH with a molar ratio of 1:1.5 4 , mix well in a mortar;

[0024] 2. The mixture was reacted under the protection of argon at 600°C for 30 minutes; the obtained product was finely ground, washed three times with distilled water and absolute ethanol, and then vacuum-dried at 60°C for 12 hours to obtain the product.

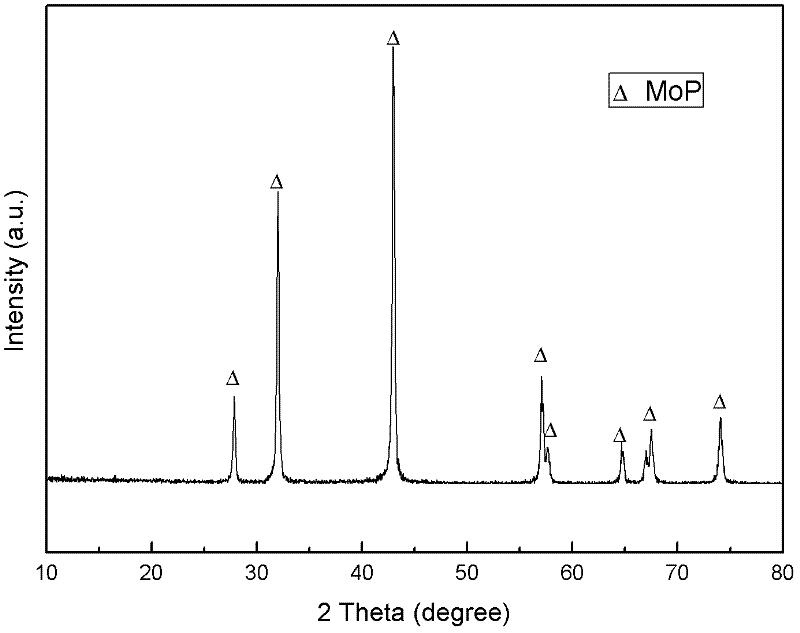

[0025] figure 1 is the XRD pattern of the obtained material. It can be seen from the standard card that the synthesized material is MoP.

Embodiment 2

[0027] 1. Weigh the above precursor and KBH with a molar ratio of 1:2 4 , mix well in a mortar;

[0028] 2. The mixture was reacted at 500°C under the protection of argon for 60 minutes; the obtained product was finely ground, washed three times with distilled water and absolute ethanol, and then vacuum-dried at 60°C for 12 hours to obtain the product.

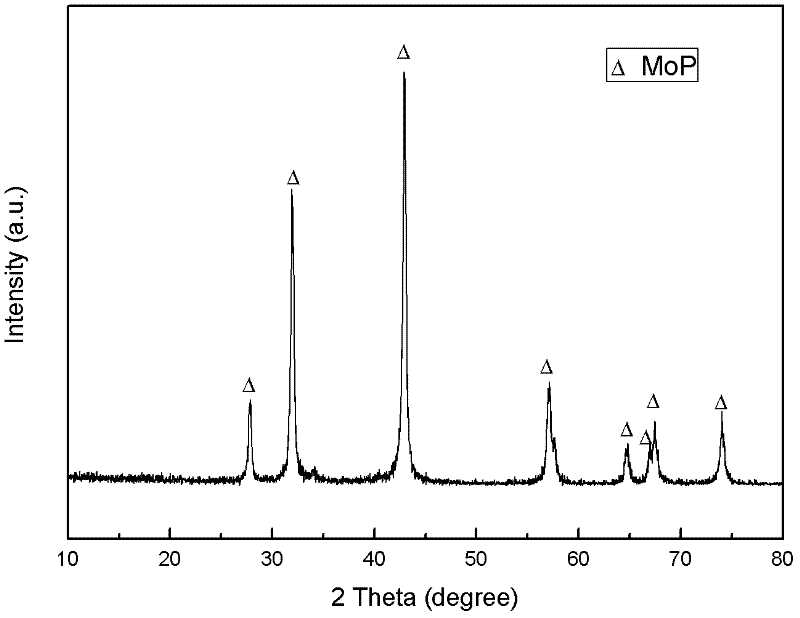

[0029] figure 2 is the XRD pattern of the obtained material. It can be seen from the standard card that the synthesized material is MoP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com