Method for measuring rotational inertia of transmission system

A technology of moment of inertia and transmission machinery, which is applied in the field of measuring the moment of inertia of the transmission system, and can solve problems such as failure to meet tension accuracy requirements, fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

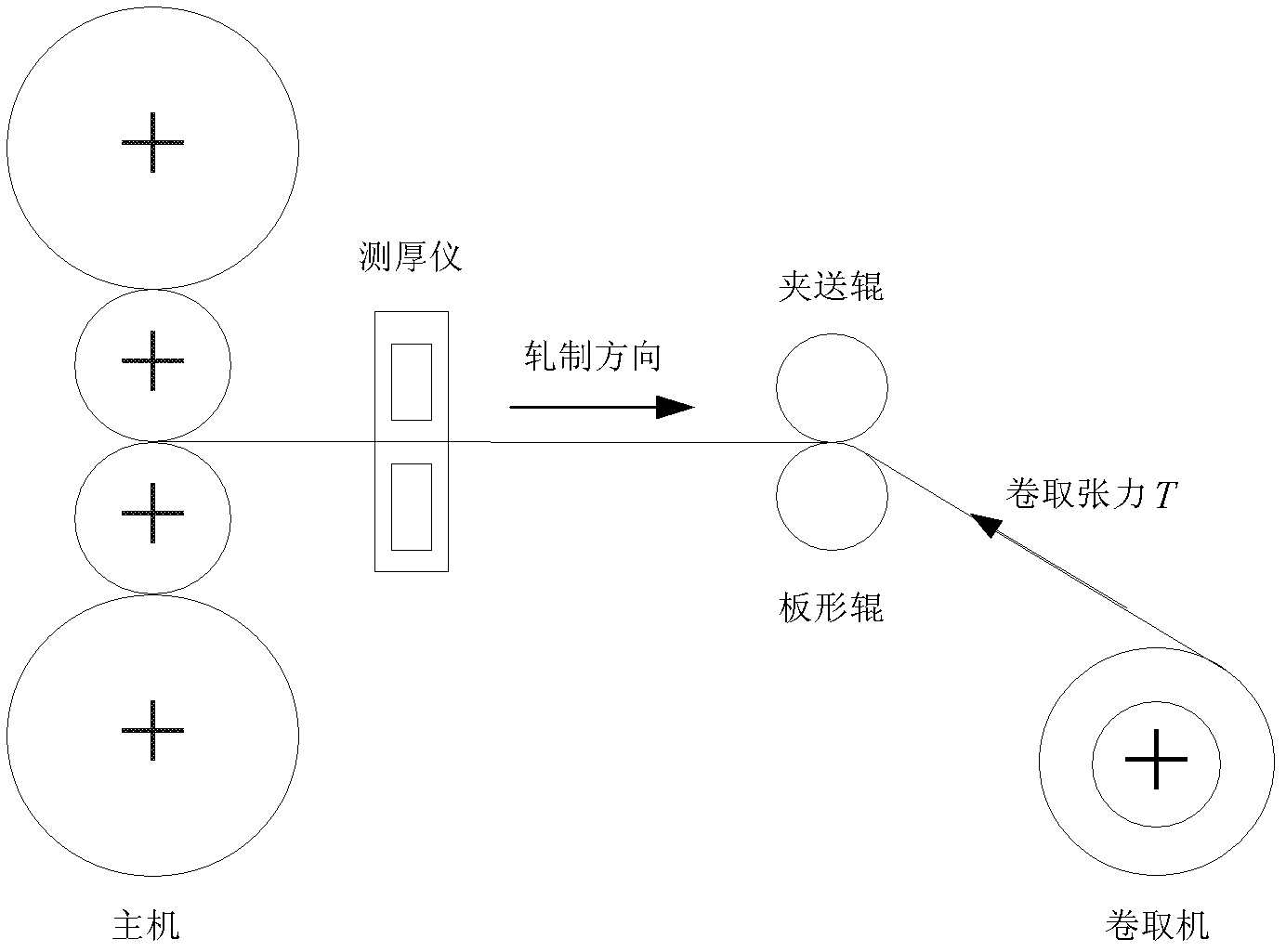

[0028] In this example, the electrical control system of an aluminum foil rolling mill, the coiler is a DC motor, using ABB's DCS800 DC transmission device, using Siemens S7-400PLC system as a test and data recording tool, the maximum speed of the coiling motor is 1197rpm, and the rated output The torque is 3600Nm.

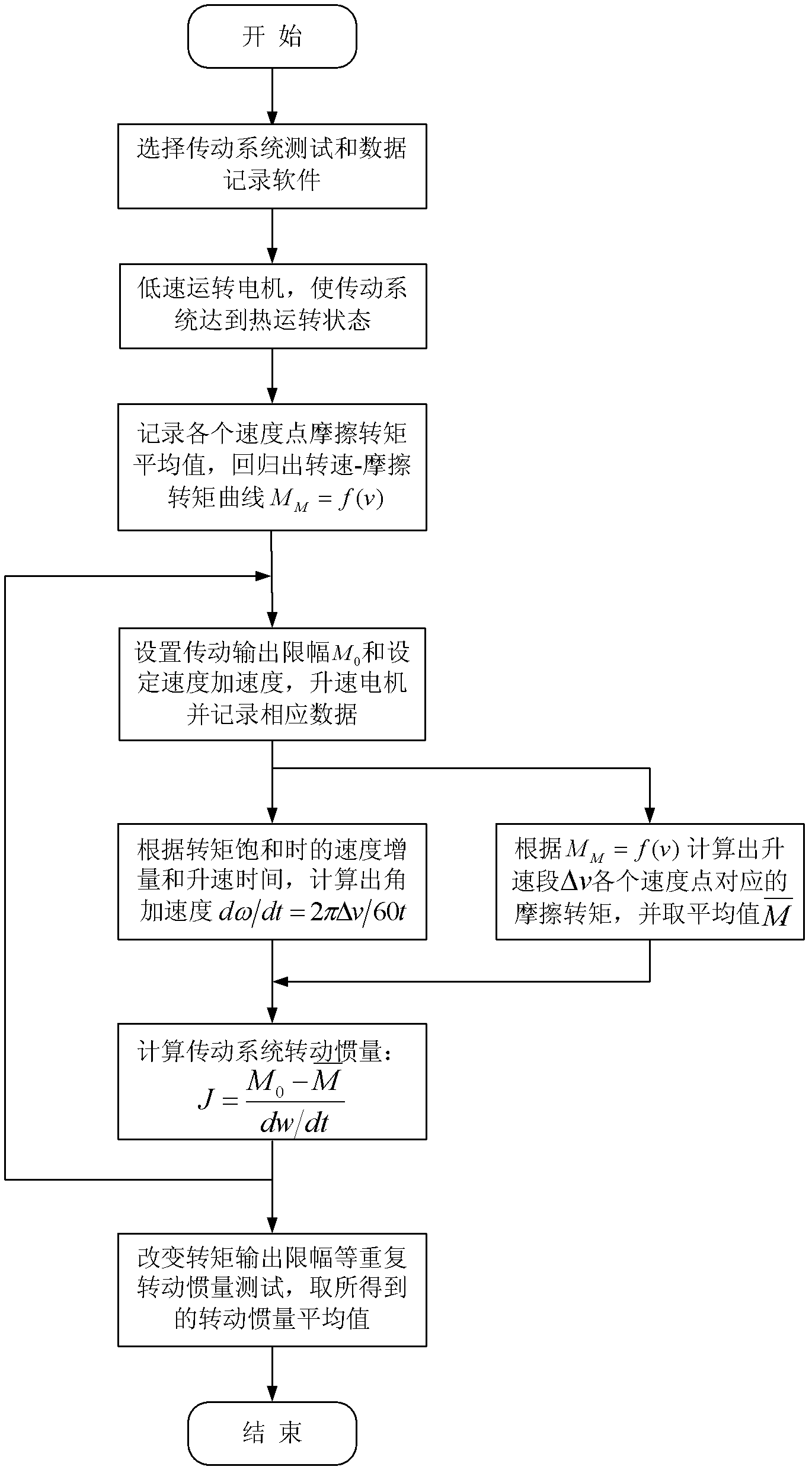

[0029] A method for measuring the moment of inertia of the transmission system in this embodiment, such as image 3 shown, including the following steps:

[0030] Step 1: The PLC system is connected to the DC transmission device through the PROFIBUS-DP network, set 51 groups of corresponding parameters in the DC transmission device DCS800, read the actual speed and output torque of the motor to the PLC system, and record the actual data of each cycle to the Save in the data module of PLC;

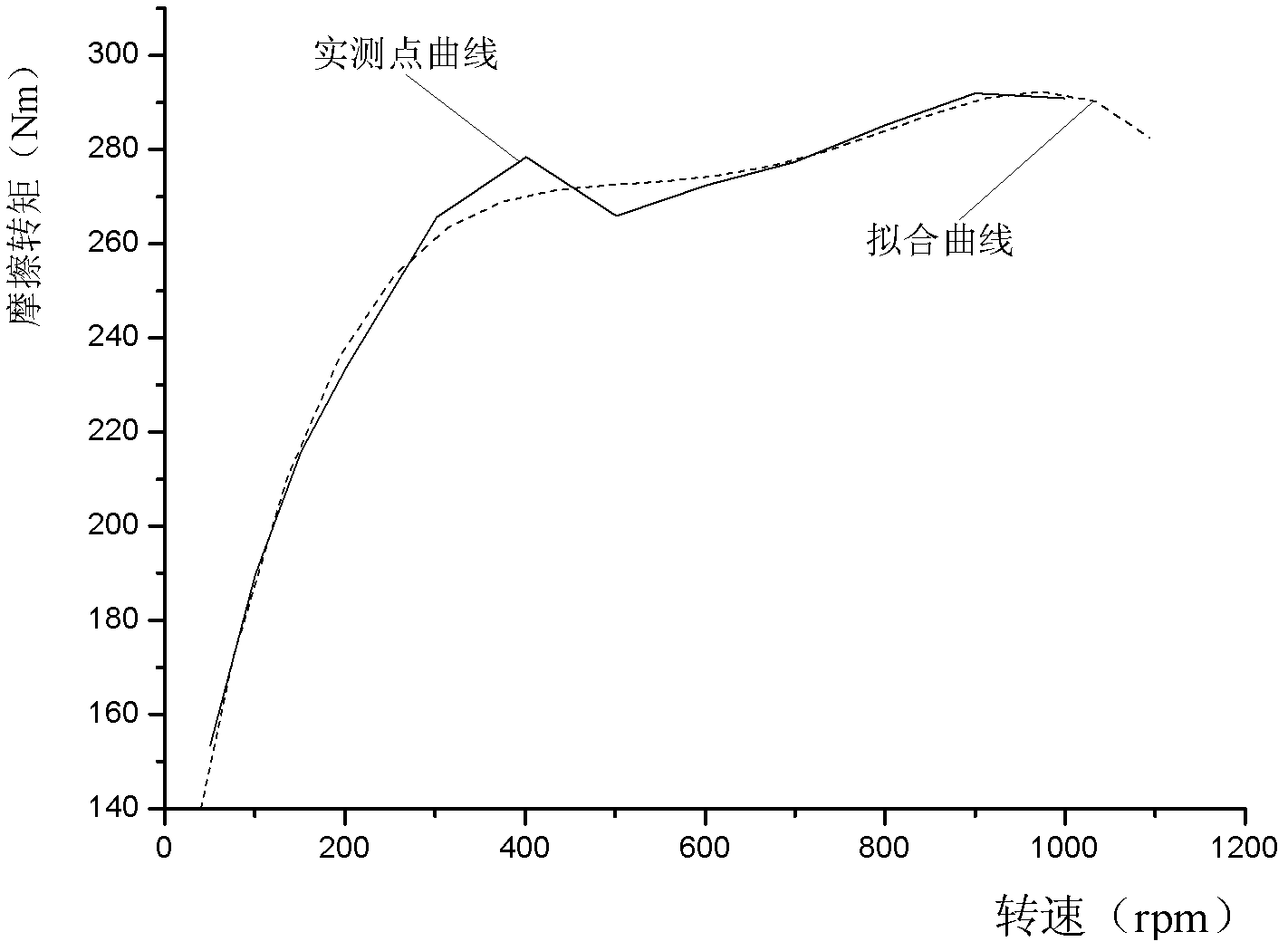

[0031] Step 2: Run the motor at a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com