Magnetic bidentate imide palladium ligand catalyst and preparation method thereof

A technology of bidentate imine and catalyst, which is applied in the field of Suzuki reaction catalyst and its preparation, can solve the problems such as difficult recovery of palladium ligand catalyst, and achieve the effects of reduced activity, less loss, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

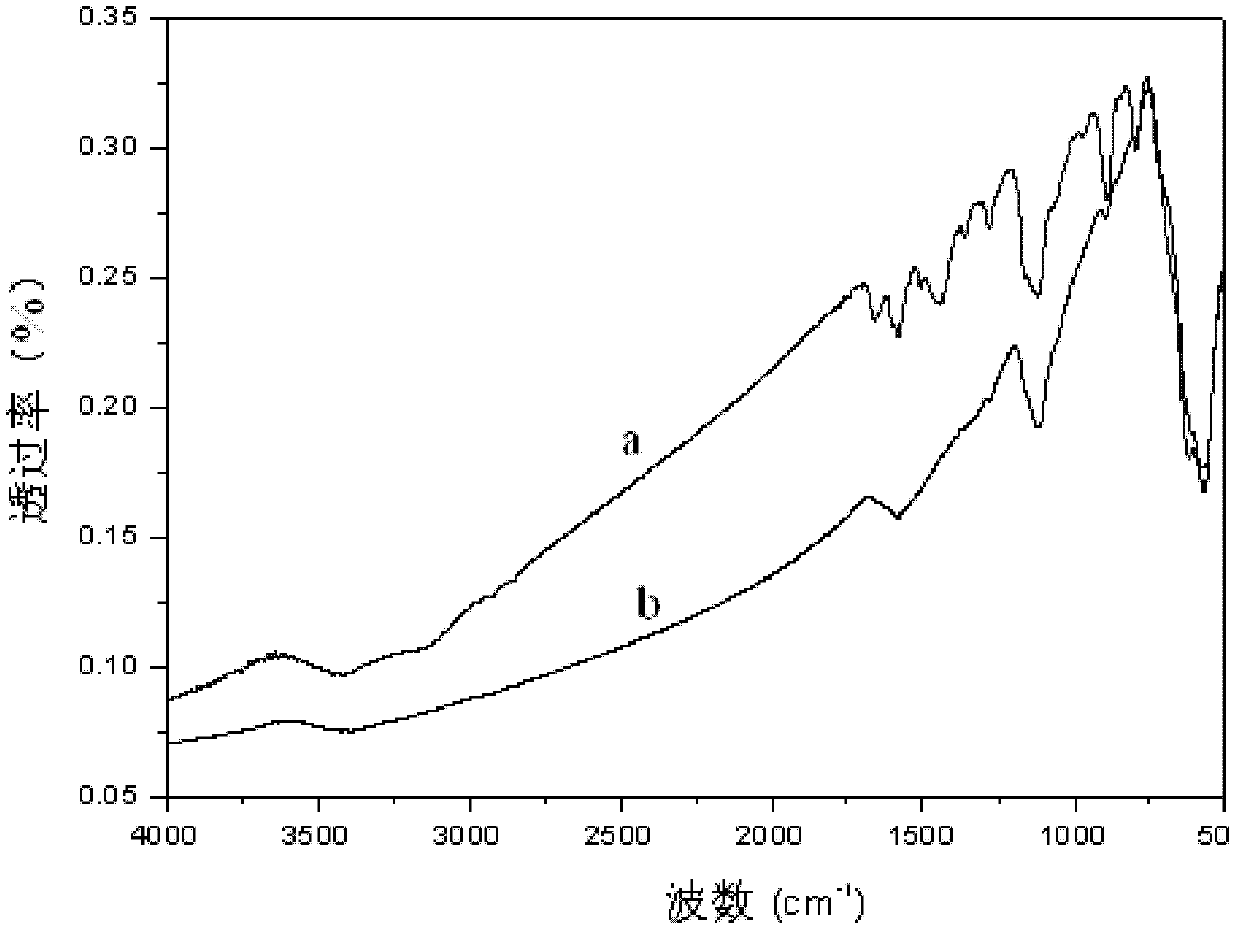

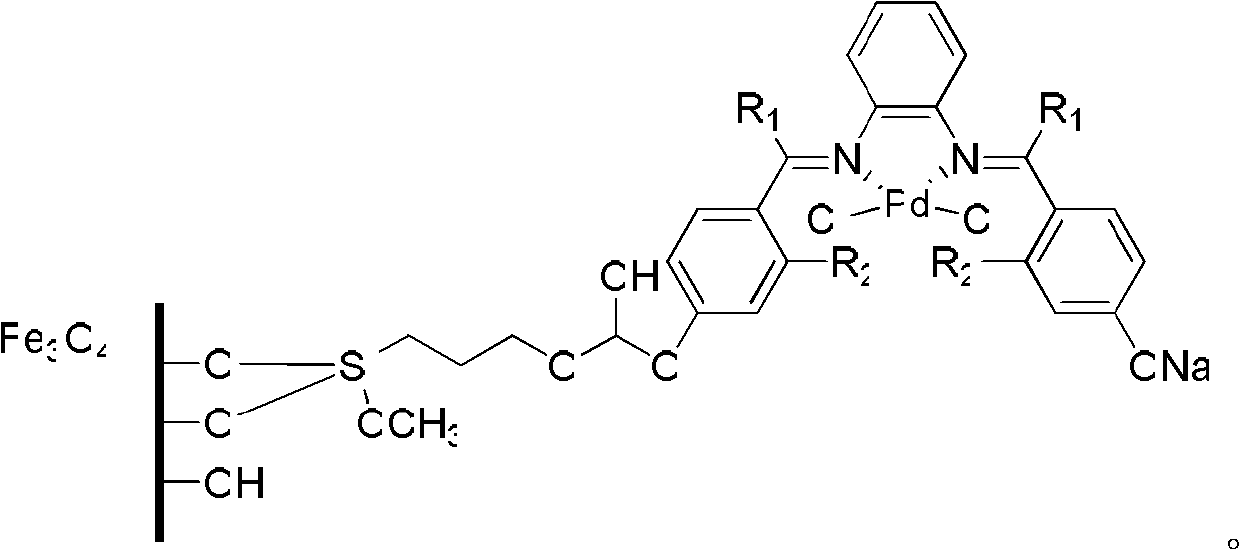

[0016] Embodiment 1: The structural formula of the magnetic bidentate imine palladium ligand catalyst of the present embodiment is:

[0017]

[0018] In this embodiment, palladium is coordinated to superparamagnetic nano-Fe containing bidentate imine ligands. 3 o 4 surface, so the entire palladium-containing catalyst has superparamagnetism and can be magnetized under an external magnetic field, so the catalyst is magnetic under the action of an external magnetic field. When the external magnetic field is removed, the magnetism disappears. With this characteristic, the catalyst can react with the external magnetic field The system is separated, the operation is simple, the catalyst is not easily lost, and the catalyst can be recovered in the reaction system under the external magnetic field. This catalyst was used in the Suzuki reaction, and the activity of the catalyst was not significantly reduced after repeated use for 7 times.

specific Embodiment approach 2

[0019] Specific embodiment two: the preparation method of the magnetic bidentate imine palladium ligand catalyst of the present embodiment is carried out according to the following steps:

[0020] 1. Fe with epoxy bonds on the surface 3 o 4 Preparation: a. Add silane coupling agent HK560 to ethanol according to the volume ratio of silane coupling agent KH560 and ethanol as 1:3-6, and then add hydrochloric acid to adjust the pH value to 5-6 to obtain acidified silane coupling agent Joint agent KH560 ethanol solution; b, under the protection of inert gas, press Fe 3 o 4 Fe 3 o 4 Add it into the acidified silane coupling agent KH560 ethanol solution, heat to 70°C ~ 80°C and stir for 3h ~ 4h, then filter under reduced pressure and vacuum dry to obtain Fe with epoxy bonds on the surface 3 o 4 ;

[0021] 2. Fe supported by bidentate imine ligand 3 o 4 Preparation: The molar ratio of bidentate imine ligand to base is 1:2~2.4, the mass volume ratio of bidentate imine ligand t...

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 2 in that the inert gas in step 1 is nitrogen or argon. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com