Visible light response photocatalysis material Ag@Ag3VO4 and preparation method thereof

A photocatalytic material and visible light technology, applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of many steps, complicated operations, high energy consumption, etc., and achieve simple preparation methods, low cost, The effect of reducing the recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

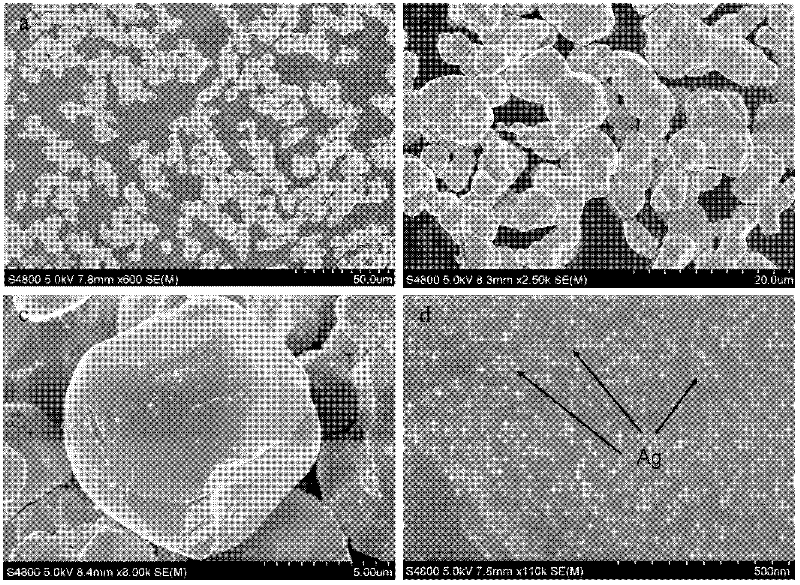

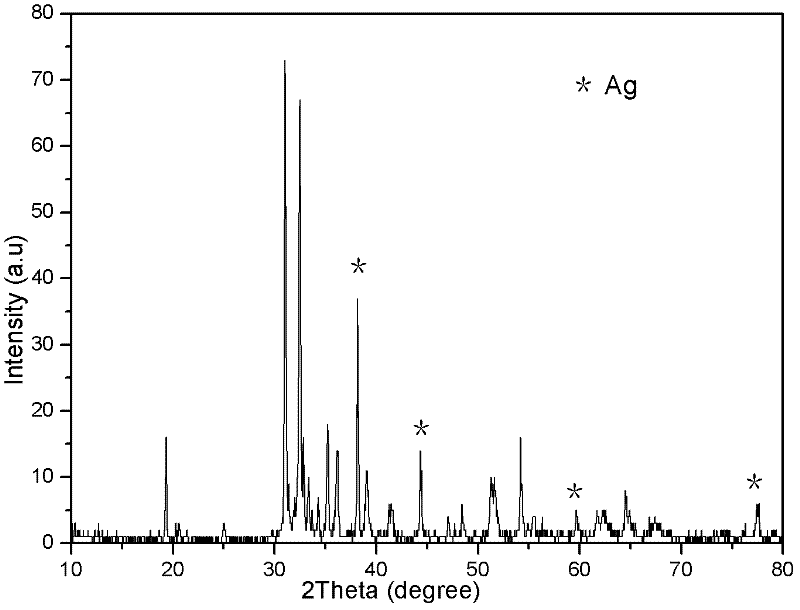

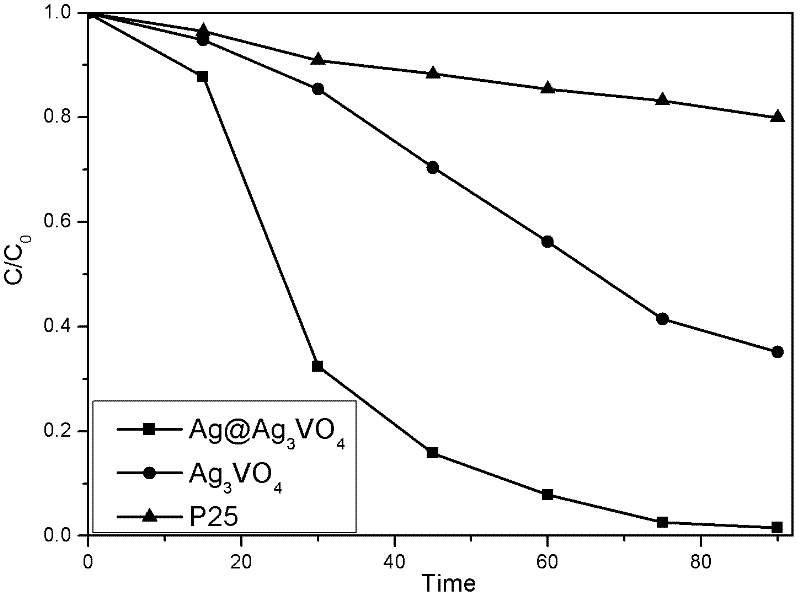

[0032] Take 0.1mol / L NaVO 4 Solution 30ml, slowly drop into 30.9ml 0.3mol / L AgNO 3 In the solution, stir while adding dropwise, continue magnetic stirring for 10 minutes after the drop is complete, add 1mol / L NaOH solution to adjust the pH to 8.0, stir at the same time during the adjustment process, the AgNO in the solution 3 :NaVO 4 =3.09:1 molar ratio, after pH adjustment, continue to stir for 30 minutes, then pack into a 100ml polytetrafluoroethylene reactor with a filling degree of 80% volume ratio, and put it in an oven at 180°C for 24 hours. After the reaction, it was naturally cooled to room temperature, filtered with suction, washed repeatedly with deionized water and ethanol three times, and dried in an oven at 60°C for 12 hours. Micronano powder material AgAg 3 VO 4 , electron microscope photo as figure 1 As shown, the diameter of the silver vanadate particles is 6.5-7.5 μm, and the diameter of the silver particles deposited on the surface is 5-25 nm. figure 2...

Embodiment 2

[0034] 0.1mol / L NaVO 4 Solution 30ml, slowly drop into 30.0ml 0.3mol / L AgNO 3 In the solution, stir while adding dropwise. After the drop is completed, stir magnetically for 10 minutes. Add 1mol / L NaOH solution to adjust the pH to 6.5. Stir at the same time during the adjustment process. The AgNO in the solution 3 :NaVO 4 =3:1 molar ratio, after the pH adjustment, continue to stir for 30 minutes, then put it into a 100ml polytetrafluoroethylene reactor with a filling degree of 80% volume ratio, and put it in an oven at 170°C for 20 hours. After the reaction, cool down to room temperature naturally, filter with suction, wash with deionized water and ethanol repeatedly for 3 times, and dry in an oven at 60°C for 10 hours. The obtained sample is Ag 3 VO 4 ,exist figure 2 , image 3 AgAg 3 VO 4 comparison.

Embodiment 3

[0036] 0.1mol / L NaVO 4 Solution 30ml, slowly drop into 31.5ml 0.3mol / L AgNO 3 In the solution, stir while adding dropwise. After the drop is completed, stir magnetically for 10 minutes. Add 1mol / L NaOH solution to adjust the pH to 8.0. Stir at the same time during the adjustment process. The AgNO in the solution 3 :NaVO 4 =3.15:1, after pH adjustment, continue to stir for 30 minutes, then pack into a 100ml polytetrafluoroethylene reactor, fill 70%, and put it into an oven at 180 degrees Celsius for 24 hours. After the reaction, it was naturally cooled to room temperature, filtered with suction, washed repeatedly with deionized water and ethanol three times, and dried in an oven at 60°C for 12 hours. Got AgAg 3 VO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com