Preparation method and application of magnetic fluorescent nanoparticle with shell-core structure

A fluorescent nanoparticle and nanoparticle technology, applied in the fields of biomedicine and nanomaterials, can solve the problems of easy quenching of fluorescence, rough surface of nanoparticles, poor uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of embodiment 1 superparamagnetic nanoparticles

[0018] Weigh 2.71g FeCl 3 ·6H 2 O and 1.18 g FeCl 2 4H 2 O was dissolved in 50ml of distilled water. After stirring and mixing, 4mL of concentrated ammonia water was added, and stirred at room temperature for 30min. Under the action of a magnetic field, the product was collected and the supernatant was removed. The product was washed 3 times with deionized water, 200 mL each time. The particles were made up to 50 mL with deionized water.

Embodiment 2

[0019] Example 2 Fe 3 o 4 SiO 2 Preparation of nanoparticles

[0020] Take 7.5mL cyclohexane, 1.77mL Triton X-100, and 1.8mL n-hexanol in a 10mL flask, mix well; add 480μL Fe 3 o 4 Aqueous solution, stirring for 5 minutes to form water-in-oil microcapsules, then add 100 μL TEOS, stir and mix, add 60 μL ammonia water; wrap in tin foil, react for 24 hours; add an equal volume of acetone, vortex, break the microemulsion system; place in a magnetic field , let stand for a while, discard the liquid; wash the particles with acetone, absolute ethanol, and water in sequence, 50 mL / time, and vortex and ultrasonically break the particles during the washing process. The particles were resuspended in 50mL of 1M hydrochloric acid and allowed to stand at room temperature for 24h. Place in a magnetic field, let it stand for a while, and discard the liquid; wash the particles with deionized water and absolute ethanol three times, 50 mL each time; resuspend the particles in 20 mL of absol...

Embodiment 3

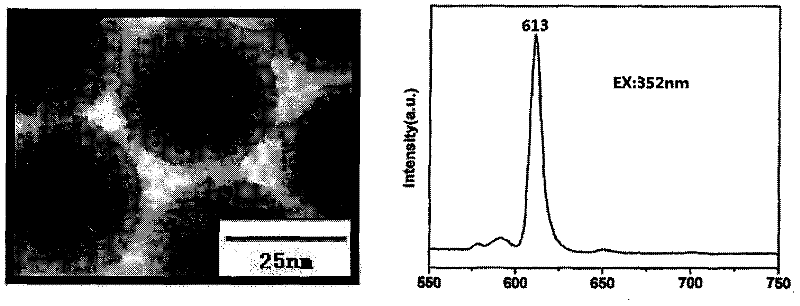

[0021] Embodiment 3 coated rare earth fluorescent complex

[0022] Add 6.3 μL triaminopropyltriethoxysilane to 50 μL 0.1M BHHCT solution, vortex and mix well, let stand at room temperature for 20 minutes, add 50 μL 0.1M EuCl 3 solution, mix well, and stand at room temperature for 20min. This liquid is transferred to the Fe obtained in embodiment 2 3 o 4 SiO 2 In absolute ethanol suspension, protected from light, reflux at 80°C for 18h. Place in a magnetic field, let it stand for a while, and discard the liquid; wash the particles 3 times with deionized water and absolute ethanol, 50 mL each time. After the particles were dried in a vacuum oven at 60° C. for about 12 hours, magnetic nanoparticles coated with fluorescent complexes were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com