Method for injecting surface discharge active material to oxidized ammonium sulfite or ammonium nitrite

A technology for oxidizing ammonium sulfite and creeping discharge, which is applied in ammonium nitrate, chemical instruments and methods, separation methods, etc., can solve the problems of complex radiation beam source technology, and achieve the effect of high oxidation efficiency and fast oxidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

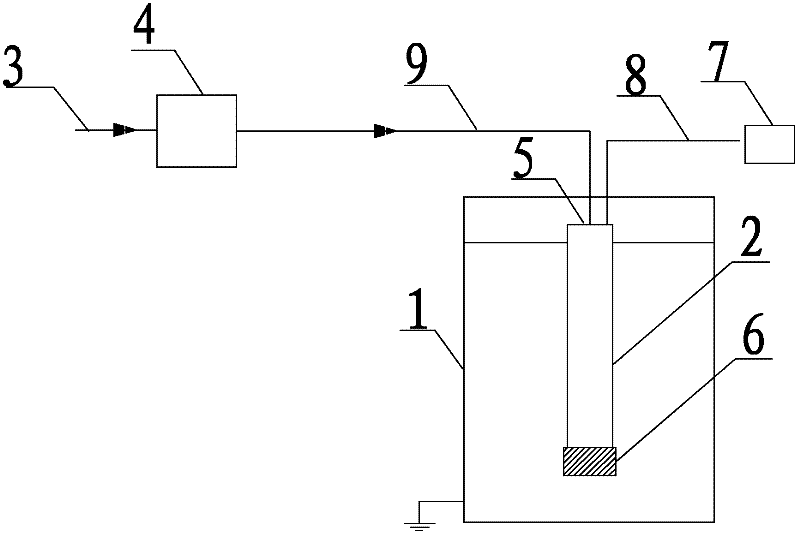

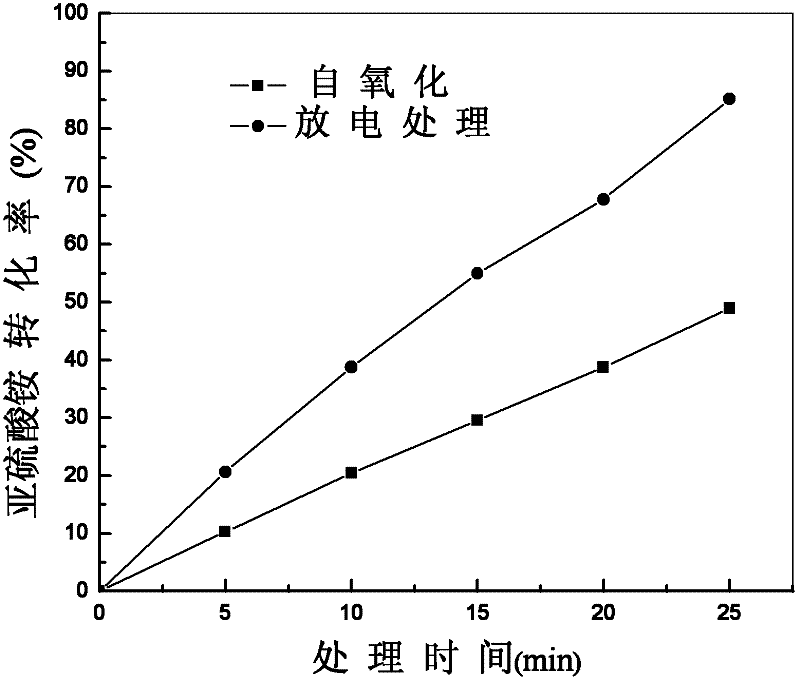

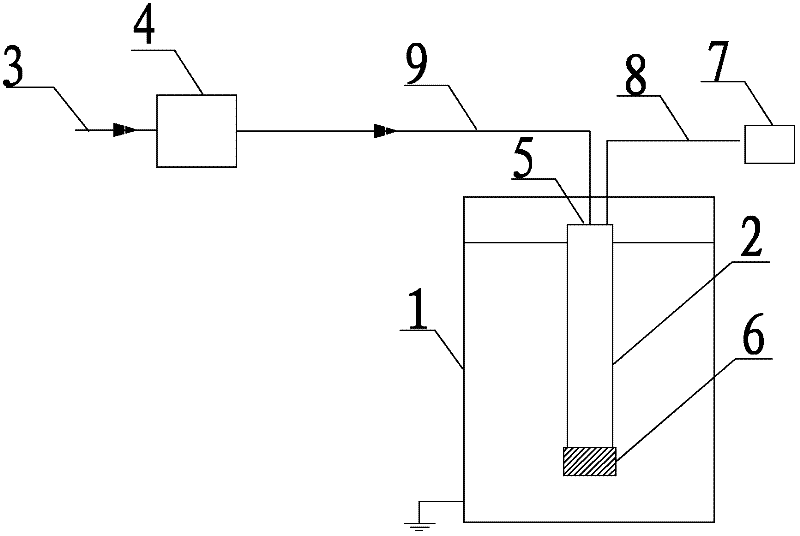

[0013] A method for injecting surface discharge active material into oxidized ammonium sulfite or ammonium nitrite according to the present invention is that the surface discharge system is placed in the reaction pool of ammonium sulfite or ammonium nitrite, and the oxygen-containing gas enters the entrance of the surface discharge system. Under the action of the surface discharge plasma, the oxygen-containing gas is transformed into an active gas containing ozone and atomic oxygen, and enters the solution in the reaction pool from the nozzle at the outlet of the surface discharge system. In the reaction pool, the active material and the ammonium sulfite or Ammonium nitrate reacts and converts to ammonium sulfate or ammonium nitrate.

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. The nitrite concentration used is 0.1mol / L-0.3mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com