Farm-oriented coiled double-welded-side plastic greenhouse film, preparation method thereof and special double-welded-side device

A preparation process and technology for plastic sheds, which are applied in the fields of botanical equipment and methods, horticulture, greenhouse cultivation, etc., can solve problems such as defects in the use of shed film, and achieve the effect of solving transportation and logistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

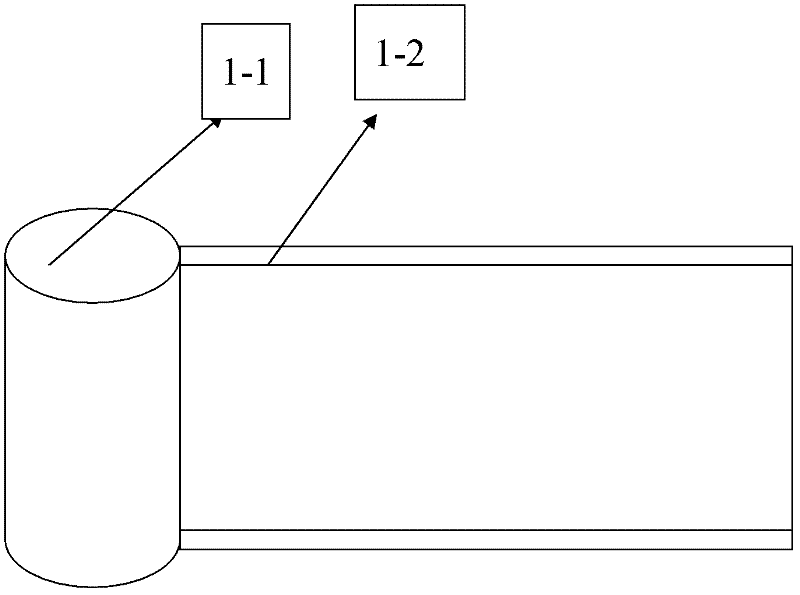

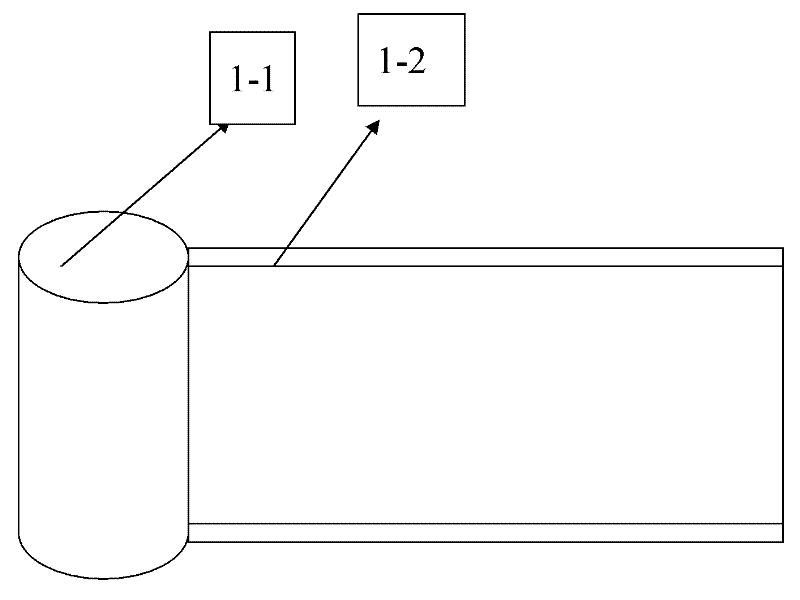

[0011] Such as figure 1 As shown, the agricultural rolling double-welded plastic shed film has a rolled shed film body 1-1, and it is formed with mutually parallel welded edges 1-2 for passing through fixed ropes on both sides of the shed film body 1-1. The welded edge 1-2 is a through elongated hole formed by flanging and welding the side shed film bodies 1-1 on both sides.

[0012] In the present invention, the welded edges for wearing ropes are made by rolling up the two sides during the production and winding process of the shed film. The double-welded edge shed film produced in this way is tightly wound, and the overall volume of the shed film is small, which is convenient for transportation, and ropes are worn on both sides, so it is easy to fix and use.

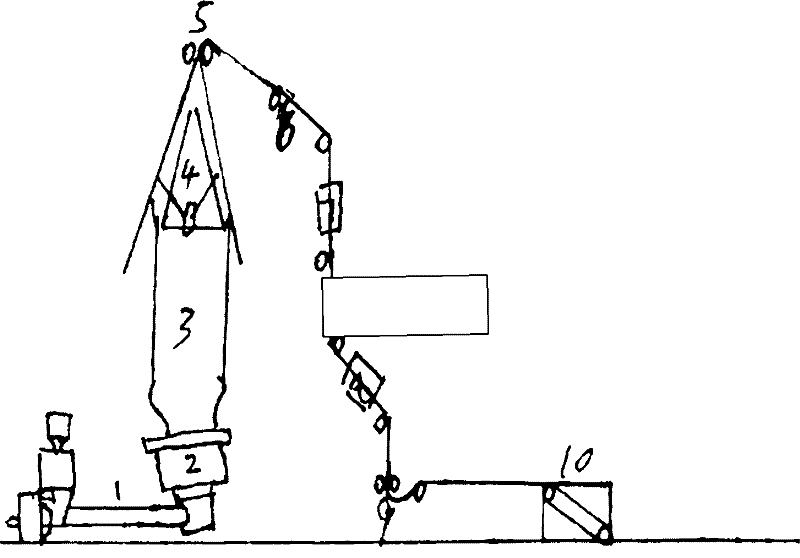

[0013] The preparation process of the agricultural double-welded edge plastic shed film in rolls is to add a second plastic heat sealer after the plastic heat sealer of the plastic film extruder, and add a double-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com