Control method of normal-pressure low-temperature plasma power supply and power supply device

A technology of low-temperature plasma and power supply device, which is applied in the direction of output power conversion device, electrical components, AC power input conversion to AC power output, etc., which can solve the problems of perforation and damage of the processed fabric, and achieve the purpose of avoiding perforation and damage, The effect of improving reliability and facilitating flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

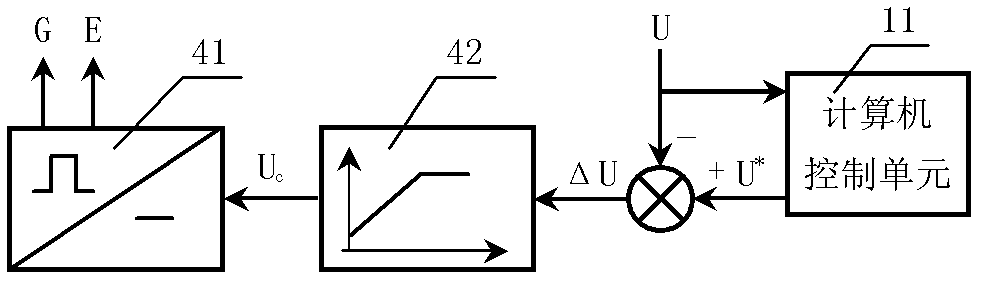

[0028] see figure 1, the present invention is an atmospheric pressure low temperature plasma power supply device for fabric surface treatment, mainly composed of a rectification filter unit 1, a Buck converter 2, a Hall voltage transformer 3, a Buck converter control unit 4, and a Hall current transformer 5. H-bridge inverter control unit 6, H-bridge inverter 7, DC blocking capacitor 8, high-frequency step-up transformer 9, computer control unit 11 and auxiliary power supply unit 12. The AC input side of the rectifier bridge in the rectification filter unit 1 is input from the mains; the straight uncontrollable DC output from the rectification filter unit 1 is sent to the input end of the Buck converter 2; the straight controllable DC output from the Buck converter 2 Send it to the DC input terminal of the H-bridge inverter 7; the AC output terminal of the H-bridge inverter 7 is connected to the primary side winding of the high-frequency step-up transformer 9 after being passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com