Die-casting connecting method and tool for cable connector

A technology of cable joints and connection methods, which is applied in the direction of connection, circuits, electrical components, etc., can solve the problems of poor connection between cables and joints, inconvenient construction, overheating, etc., achieve beautiful and regular appearance, improve the degree of beauty, and reduce resistance rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

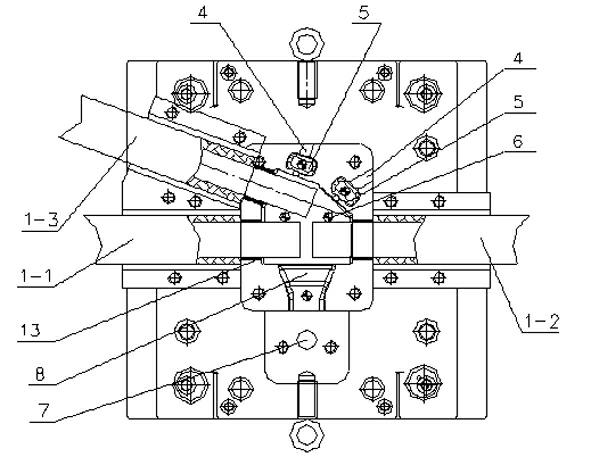

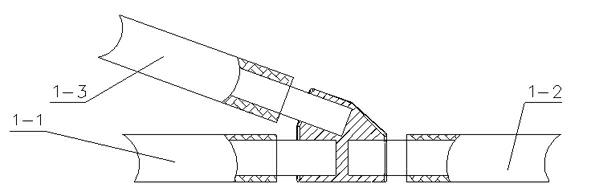

[0026] Step 1. Treatment of the cables Ⅰ1-1, Ⅱ1-2 and Ⅲ1-3 to be die-cast: cut off the rubber sleeves at the ends of the cables Ⅰ1-1, Ⅱ1-2 and Ⅲ1-3 with a knife, and cut off the rubber sleeves with copper wire The ends of cables I1-1, II1-2 and III1-3 with rubber sheaths are bound tightly and coated with a layer of paste flux.

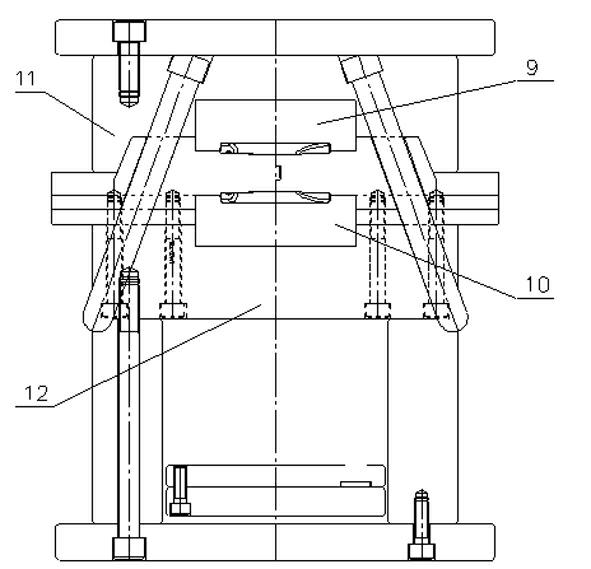

[0027] Step 2. Put the ends of the cables I1-1, II1-2 and III1-3 to be connected into the upper mold core 9 of the die-casting mold after tinning;

[0028] Step 3, pressing the upper mold core 9 of the die-casting mold on the lower mold core 10 and fixing the upper mold core 9 and the lower mold core 10 with bolts;

[0029] Step 4. Quickly press and inject the molten copper water into the die-casting mold through the sprue sleeve 7 and the inner gate 8 of the die-casting machine, and the temperature of the copper water is 1100°C--1300°C;

[0030] Step 5. During die-casting, use the external force of the die-casting head and melted copper water to remo...

Embodiment 2

[0033] Compared with Embodiment 1, only step 1 and step 2 are different, the end of cable IV2-2 is connected with the middle part of cable V2-1 to form cable joint II2, see attached Figure 4 ; Its steps 1 and 2 are:

[0034] Step 1. Treatment of the cable V2-1 and cable IV2-2 to be die-cast: cut off the rubber sheath at the end of the cable IV2-2 with a knife, tie the end of the cable IV2-2 with the rubber sheath removed and paint Apply a layer of paste flux; use a knife to cut off the rubber sheath in the middle of the cable V2-1, use copper wire to tie the middle part of the cable V2-1 with the rubber sheath removed and apply a layer of paste flux;

[0035] Step 2 is: tinning the end of the cable IV2-2 to be connected, tinning the middle part of the cable V2-1 to be connected, and putting the end of the cable IV2-2 and the middle part of the cable V2-1 into the The upper core 9 of the die-casting mould.

Embodiment 3

[0037] Compared with Example 1, only step 1 and step 2 are different, the ends of cable VI3-1 and cable VIII3-3 are connected with the middle part of cable VII3-2 to form cable joint III3, see appendix Figure 5 ; Its steps 1 and 2 are:

[0038] Step 1: Treat the cables Ⅵ3-1, Ⅷ3-3 and Ⅶ3-2 to be die-casted, cut off the rubber sheaths at the ends of the cables Ⅵ3-1 and Ⅷ3-3 with a knife, and cut off the rubber sheathed cables with copper wire Bind the ends of Ⅵ3-1 and cable Ⅷ3-3 tightly and apply a layer of paste flux; use a knife to cut off the rubber sheath in the middle of the cable Ⅶ3-2, and use a copper wire to cut off the rubber sheath in the middle of the cable Ⅶ3-2 Bind tightly and apply a layer of paste flux;

[0039] Step 2: Tin the ends of the cables VI3-1 and VIII3-3 to be connected, tin the middle of the cable VII3-2 to be connected, and tin the ends of the cables VI3-1 and VIII3-3 The middle part of the cable VII3-2 is put into the upper mold core 10 of the die-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com