Energy-saving vacuum distilling system

A distillation furnace, energy-saving technology, applied in the field of vacuum distillation furnace system, can solve the problems of large current in the power system, unreasonable distribution of the temperature field of the distillation structure, high energy consumption of the product, etc., to reduce the current of the zero line circuit loop, and flexible assembly methods Variable, lower production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

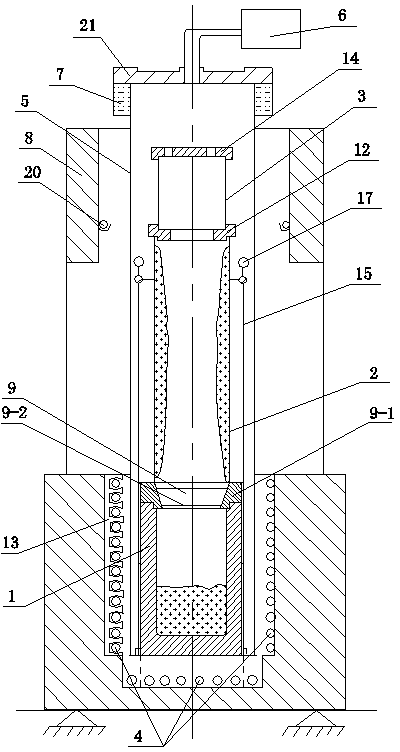

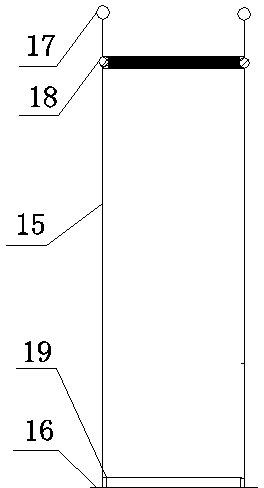

[0026] like figure 1 and figure 2 As shown, an energy-saving vacuum distillation furnace system includes a distillation crucible 1, a condensation crystallization tube 2, a secondary condensation chamber 3 and a spiral resistance heating wire 4. The distillation crucible 1 and the condensation crystallization tube 2 of the distillation furnace system are independent of each other, so The upper end of the condensation crystallization tube 2 is provided with an auxiliary condensation chamber 3; the two sides and the bottom of the distillation crucible 1 are evenly provided with spiral resistance heating wires 4, and these spiral resistance heating wires 4 form a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com