High strength oil fence with internal ballast chains

An oil boom, high-strength technology, used in the cleaning of open water surfaces, water conservancy projects, general water supply conservation, etc. Difficulty and other problems, to achieve the effect of significant application effect, increase the overall tensile capacity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

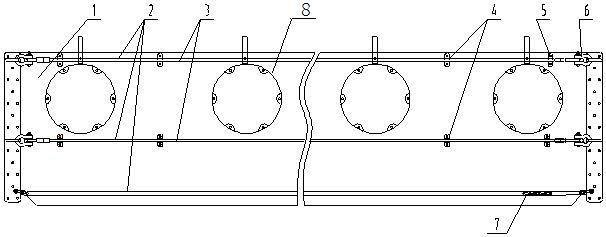

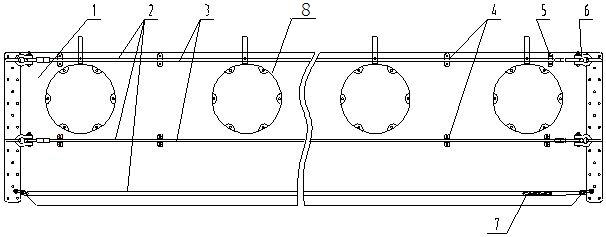

[0014] see figure 1 , a high-strength oil containment boom provided with internally enclosed ballast chains, characterized in that the oil containment boom includes an oil containment boom body 1, an external solid float 8 and a tensile device 2 arranged on the oil containment boom body 1;

[0015] The oil boom body 1 is in the shape of a strip, and the oil boom body 1 is made of oil-resistant rubber cloth; two or three longitudinal tensile devices 2 are provided on the upper, middle or lower parts; the external solid floats 8 are separated by Uniformly and correspondingly fastened on the upper part of the oil boom body 1;

[0016] The tensile device 2 is composed of two groups, two groups of stainless steel wire ropes 3 and multiple sets of guard plates 4 and ballast c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com