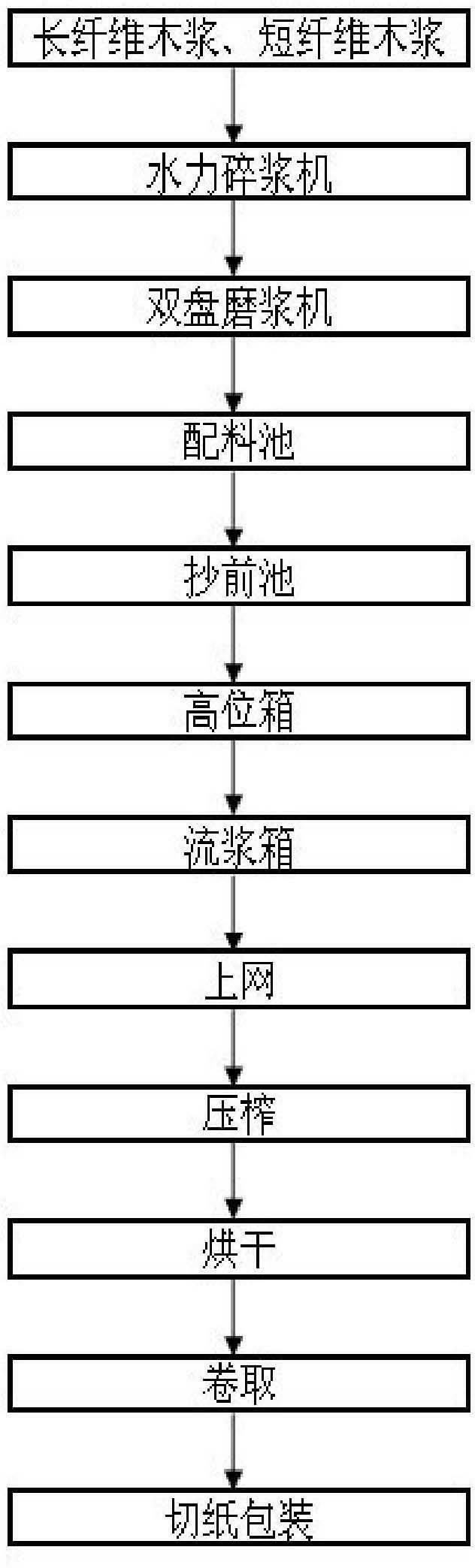

Cotton paper papermaking process

A papermaking process and tissue paper technology, applied in papermaking, textiles, papermaking, paper, etc., can solve the problems of strength wet strength, air permeability, softness, and water absorption that cannot fully meet the needs of high-end markets, achieving good absorbency, The effect of good uniform performance and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Long-fiber wood pulp and short-fiber wood pulp, with a weight ratio of 80:20, are crushed by a hydropulper, and then beaten by a double-disc refiner. The beating method is long-fiber viscous beating, which requires fiber height Silk broom, swelling and fibrillation, try to avoid cutting the fiber to maintain the high strength of the fiber, adopt the method of gradually increasing the weight, cutting the knife in sections, and beating for a long time, that is, the first-stage beating current is 100A, the second-stage beating current is 120A, and the third-stage beating current is 120A. The stage current is 140A, the beating time is controlled at 2 hours, the beating degree is controlled at 35 ° SR, the beating concentration is controlled at 3.2%, and the wet weight is controlled at 11g. 50kg of paper is added to the wet strength agent. During operation, first dilute the wet strength agent in water to a solution with a concentration of 0.5-1.0%, then add it slowly and stir...

Embodiment 2

[0030] Long-fiber wood pulp and short-fiber wood pulp, with a weight ratio of 80:20, are crushed by a hydropulper, and then beaten by a double-disc refiner. The beating method is long-fiber viscous beating, which requires fiber height Silk broom, swelling and fibrillation, try to avoid cutting the fiber to maintain the high strength of the fiber, adopt the method of gradually increasing the weight, cutting the knife in sections, and beating for a long time, that is, the first-stage beating current is 105A, the second-stage beating current is 125A, and the third-stage beating current is 125A. The stage current is 145A, the beating time is controlled at 2 hours and 10 minutes, the beating degree is controlled at 37°SR, the beating concentration is 2.9%, and the wet weight is 10.5g. Add the wet strength agent in an amount of 60kg. During operation, first dilute the wet strength agent in water to a solution with a concentration of 0.5-1.0%, then add it slowly and stir evenly. Tran...

Embodiment 3

[0034] The long-fiber wood pulp and short-fiber wood pulp, with a weight ratio of 85:15, are disintegrated by a hydropulper, and then beaten by a double-disc refiner. Silk broom, swelling and fibrillation, try to avoid cutting the fiber to maintain the high strength of the fiber, adopt the method of gradually increasing the weight, cutting the knife in sections, and beating for a long time, that is, the first-stage beating current is 100A, the second-stage beating current is 120A, and the third-stage beating current is 120A. Sectional current 140A, beating time 2 hours, beating degree 38 ° SR, beating concentration 3.1%, wet weight 10.7g, the paper pulp is prepared, and transferred to the batching tank for pulping. When operating, first dilute the wet strength agent in water to a solution with a concentration of 0.5-1.0%, then add it slowly and stir evenly. Transfer to the forebear tank for dilution, screening, and purification, and add dispersant through the high-level box, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com