Model compensating method for controlling thin film deposition rate in physical gaseous phase thin film deposition process

A thin-film deposition and physical gas phase technology, applied in the field of microelectronics, can solve the problems of material intrinsic performance device characteristics deviating from design requirements, affecting the precise control of thin-film thickness, and reducing the efficiency of machine use, etc. The effect of stable microstructure and performance and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In the vacuum thermal evaporation coating process heated by resistance, the heating current I is used as the compensation object process parameter X, that is, X=I, the source material consumption and I 2 are linearly related, so T is defined as

[0065] T = ∫ 0 t Ydt = ∫ 0 t I 2 dt

[0066] The mathematical model of film deposition rate R that needs to be established has the following form:

[0067] R=aI+p 3 T 3 +p 2 T 2 +p 1 T+R 0

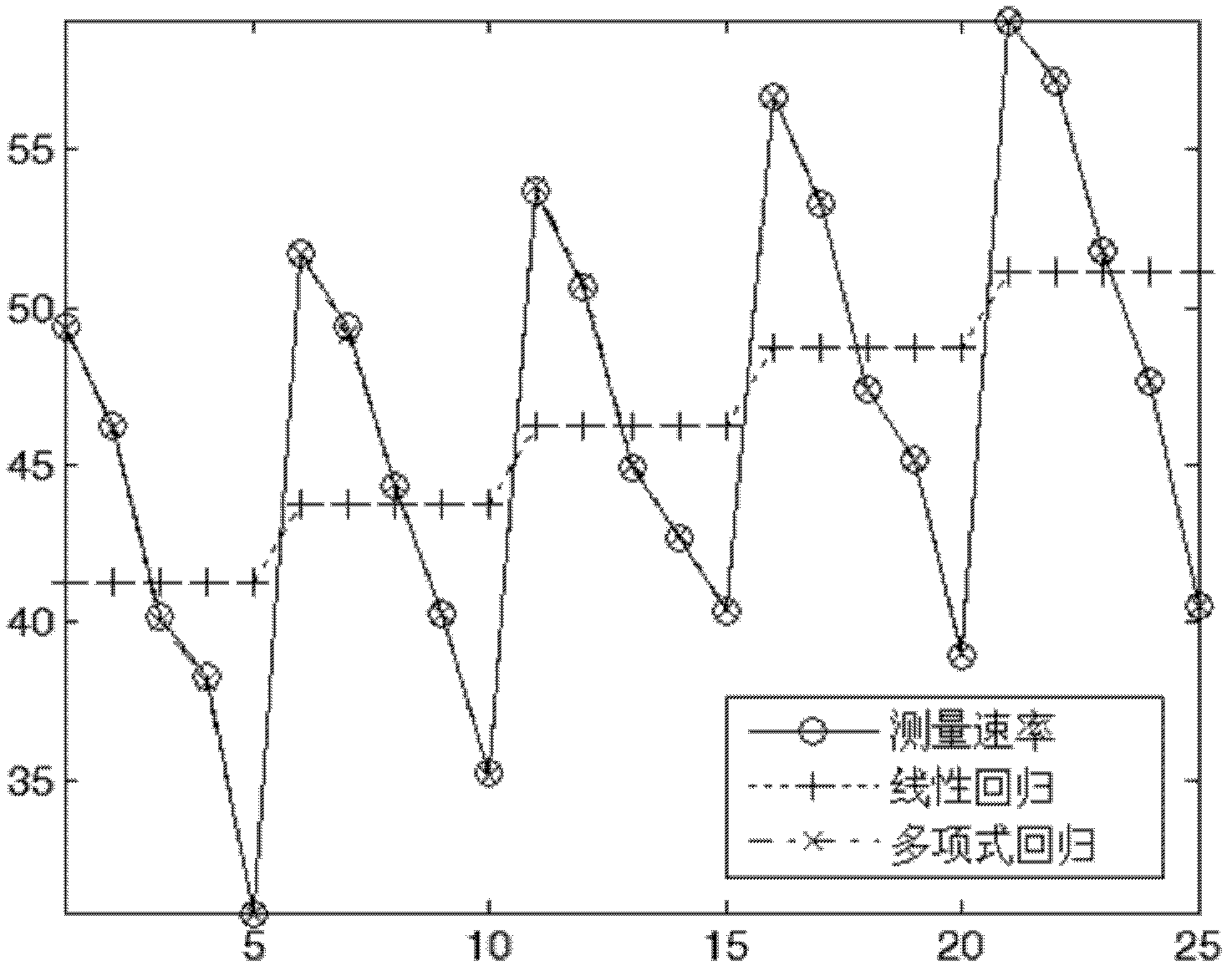

[0068] According to the test machine data, perform linear regression and polynomial regression through the Matlab program, and obtain the corresponding regression coefficients: a, p 3 ,p 2 ,p 1 and R 0 .

[0069] Compensation coefficient k 3 、k 2 、k 1 :

[0070] k 3 = - ...

Embodiment 2

[0077] In the DC magnetron sputtering coating process, through the joint action of voltage and magnetic field, ionized inert gas Ar ions are used to bombard the target to generate ions, atoms or molecules, which are deposited on the substrate to form a thin film. In addition to using DC power P as the compensation target process parameter, if the magnetic field strength B can be automatically controlled and recorded, it is also possible to use the process parameters related to the magnetic field as the compensation target process parameter. This compensation method is expected to increase the utilization rate of source materials . Since target consumption is dependent on both electric power and magnetic field strength, the integral object Y can take the product of the two.

[0078] The compensation object process parameter X and the historical record parameter T are respectively defined as:

[0079] X = B;

[0080] T = ∫ 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com