Method and equipment for purifying zinc sulfate solution

A technology of zinc sulfate solution and sulfuric acid solution, which is applied in the direction of improving process efficiency, etc., can solve the problems of rising acidity of solution, easy clogging of filter cloth, and affecting purification quality, so as to improve the activity of zinc powder, improve purification quality and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

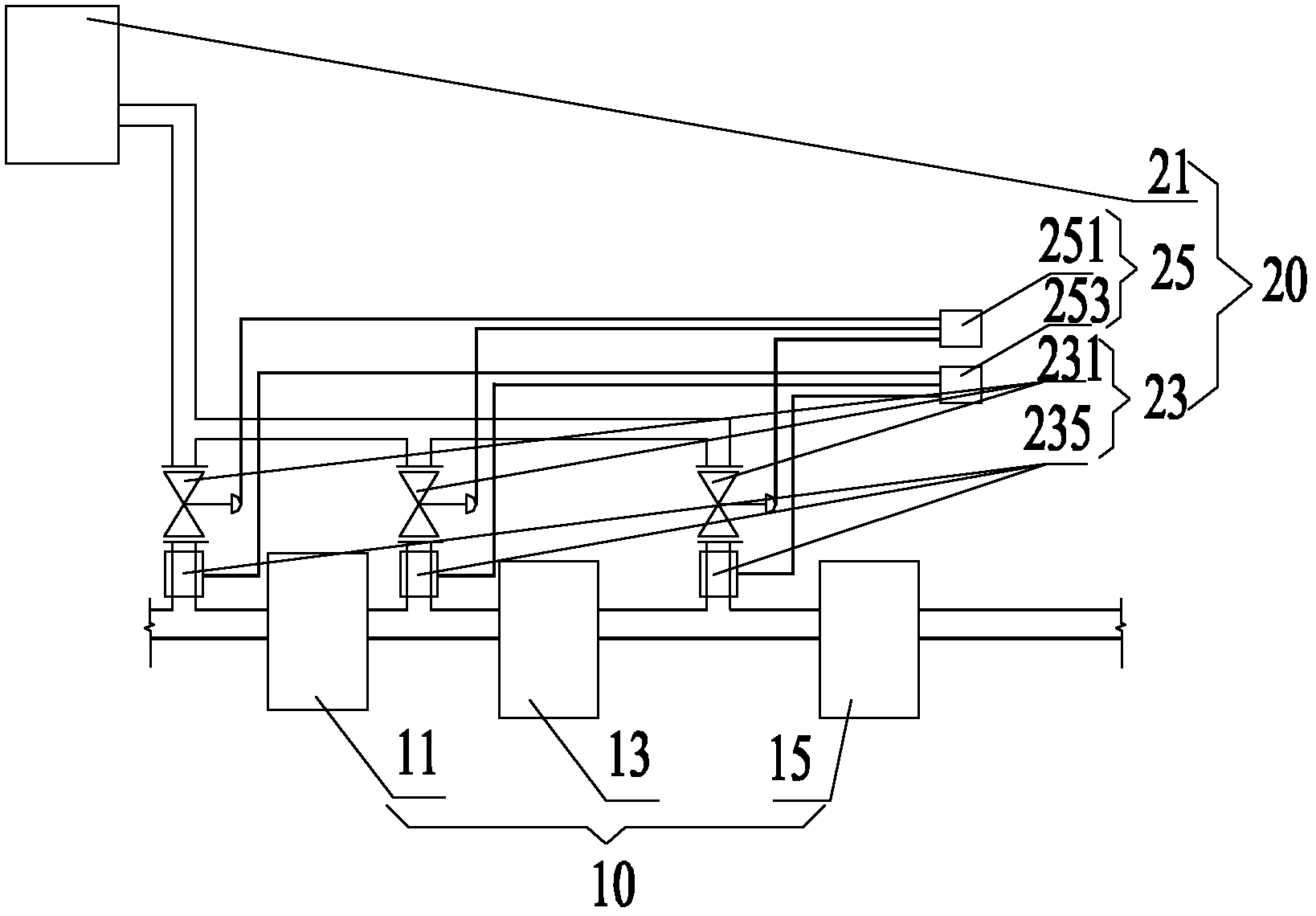

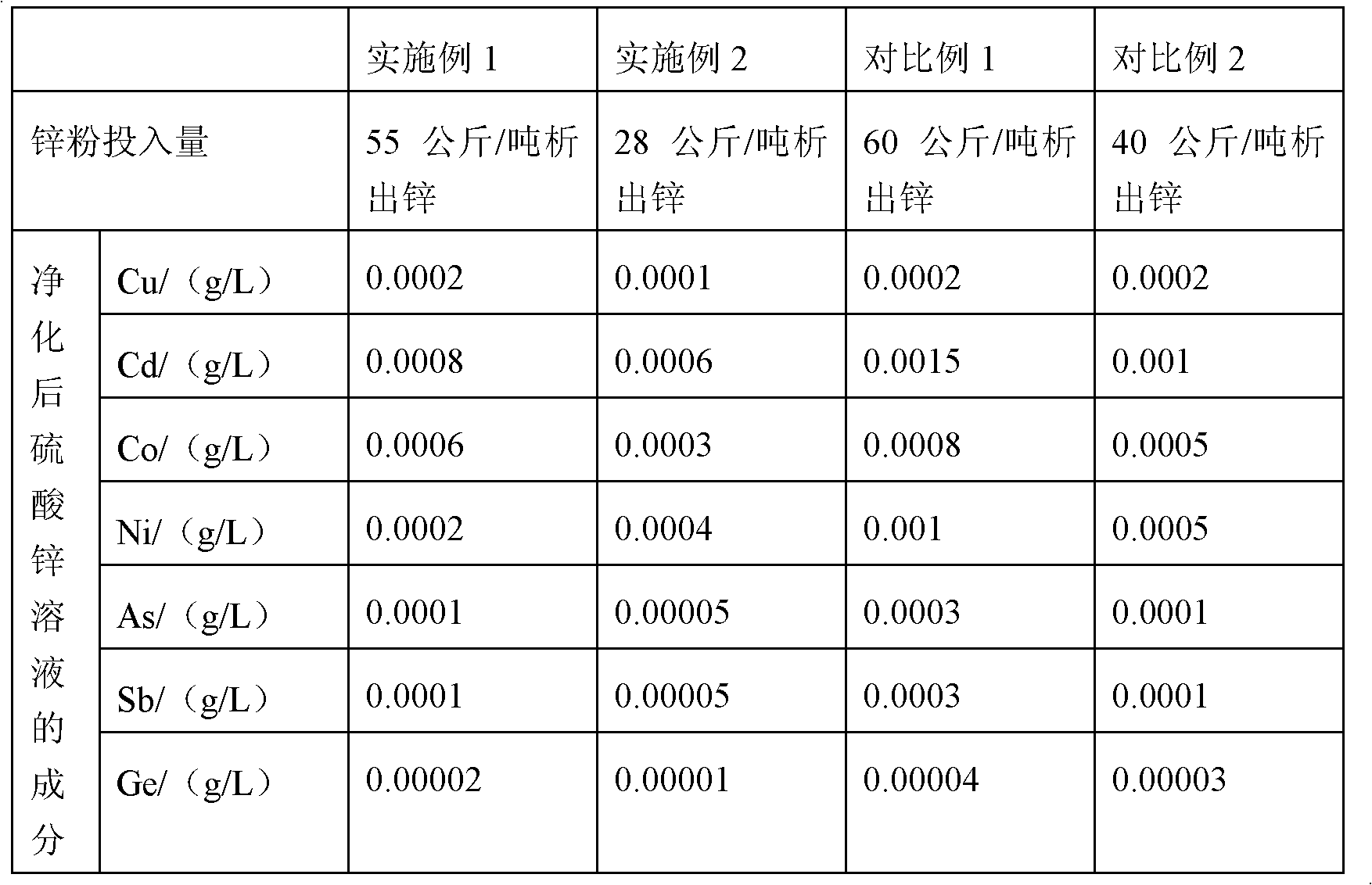

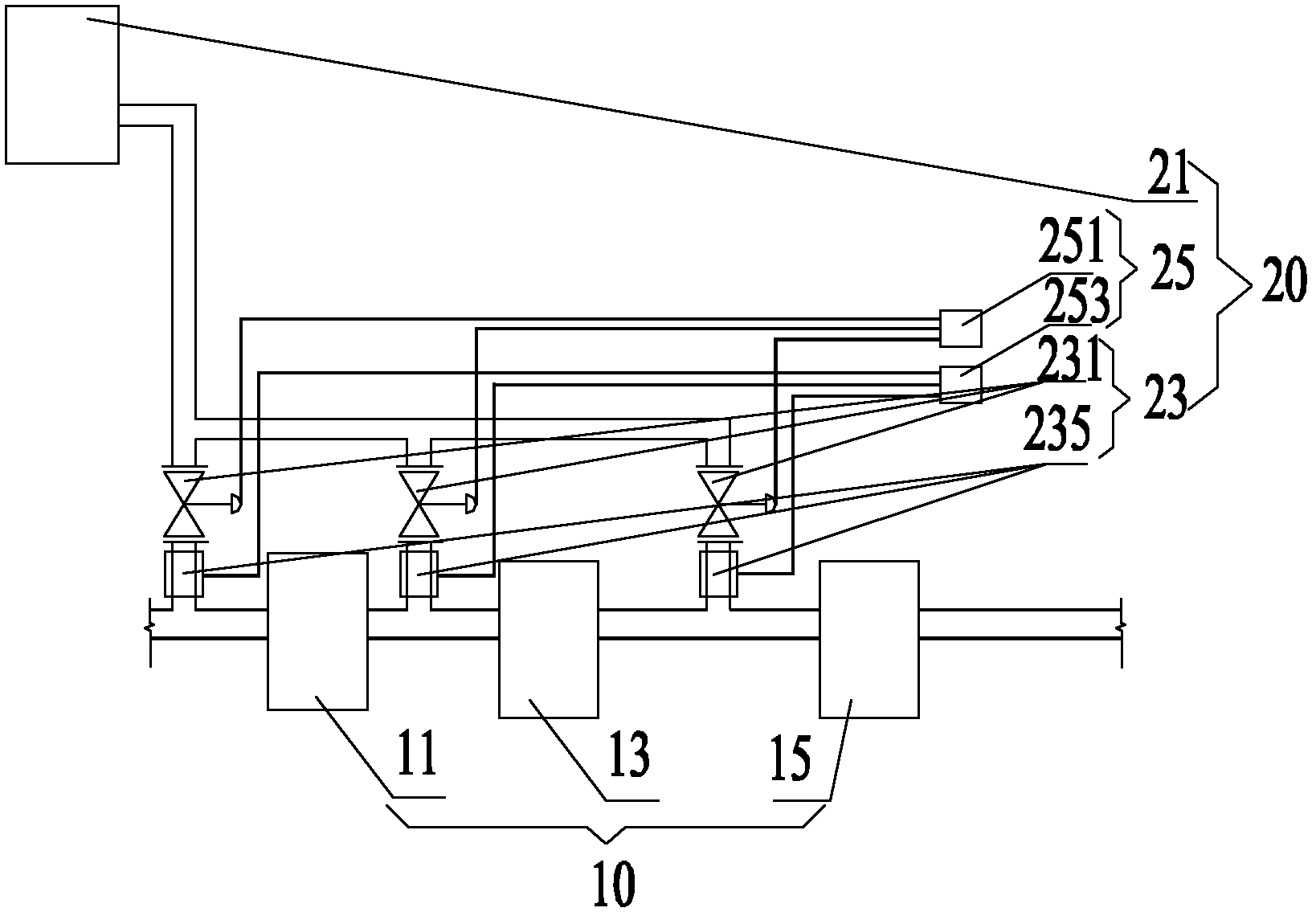

[0046] Equipment: Including 2 purification pools for removing copper and cadmium, 5 purification pools for removing cobalt and nickel, and 3 purification pools for removing cadmium, which are connected in sequence. There are 8 acid adding devices, which are respectively connected with 2 copper removal and cadmium purification pools, the first 4 cobalt removal and nickel purification pools, and the first 2 cadmium removal purification pools.

[0047] Purification method: Purify the zinc sulfate solution by using the antimony salt purification method. After adding zinc powder, each acid adding device adds acid solution to each sub-purification pool respectively, and controls the BT value of the zinc sulfate solution after being purified by each sub-purification pool. 1.2, the input amount of zinc powder in the whole reaction process is shown in Table 1.

Embodiment 2

[0049] Equipment: including 5 copper, cadmium and nickel purification pools connected in sequence, and 6 cadmium removal purification pools. There are 10 acid adding devices, which are respectively connected with 5 copper, cadmium and nickel purification pools, and the first 5 cadmium purification pools.

[0050] Purification method: Zinc sulfate solution is purified by arsenic salt purification method. After adding zinc powder, each acid adding device adds acid solution to each sub-purification pool respectively, and controls the BT value of the zinc sulfate solution after being purified by each sub-purification pool. 2.0, the input amount of zinc powder in the whole reaction process is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com