Rotary vibrating screening machine

A technology of vibrating screen and screening machine, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increased maintenance cost, frequent vibration frequency, increased production cost, etc., to ensure high efficiency, ensure continuity, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

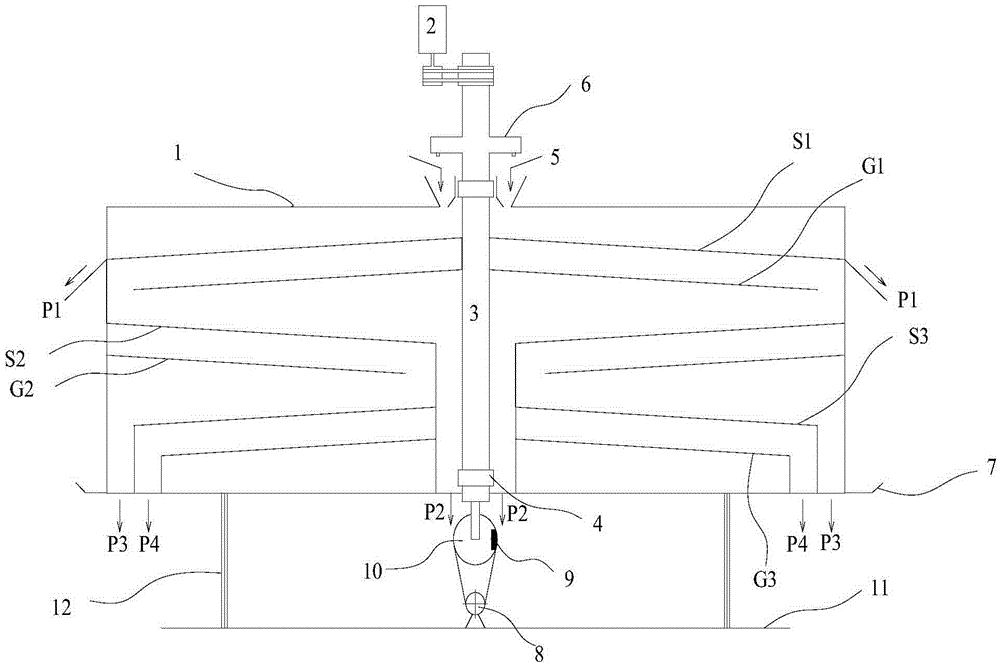

[0042] Such as figure 1 As shown, the rotary vibrating screening machine in this embodiment is a three-stage screening machine, that is, the screening machine contains three-stage screening groups.

[0043] The rotating shaft 3 is rotatably fixed on the support 7 (the support 7 is in figure 1 , 2 not fully drawn in), that is, if figure 1As shown, a bearing 4 is provided between the rotating shaft 3 and the bracket 7 , and the rotating shaft 3 forms a rotation fit with the bracket 7 through the bearing 4 ; the bracket 7 is fixed on the base 11 through the elastic support assembly 11 . The rotating motor 2 is fixed on the upper end of the bracket 7. Of course, the rotating motor 2 can also be fixed on other fixing seats, as long as it is ensured that the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com